Scores with space and robustness

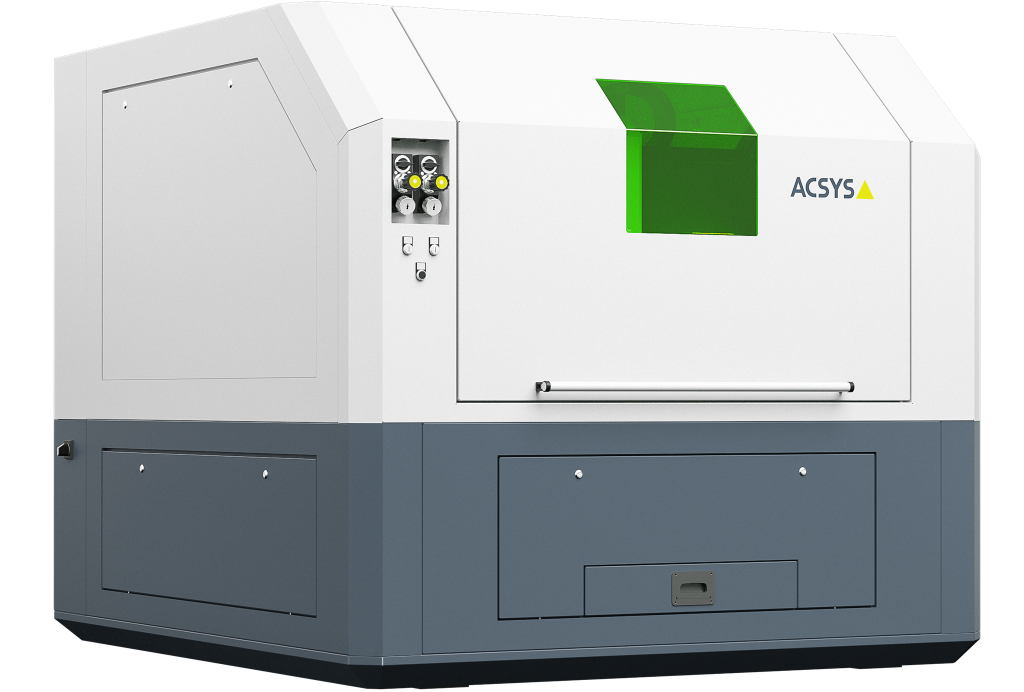

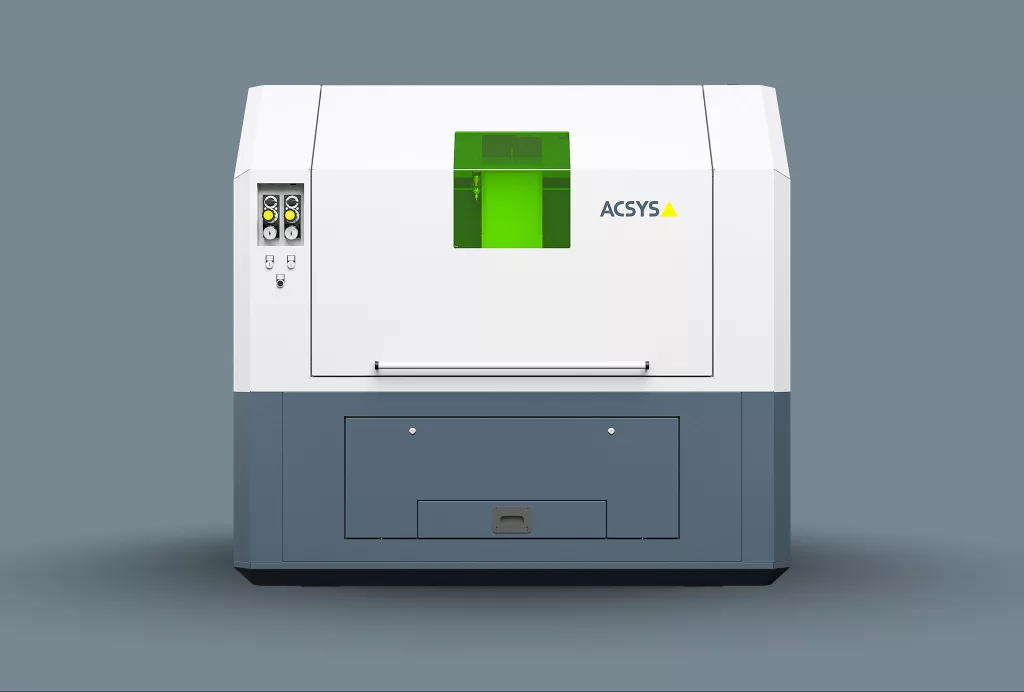

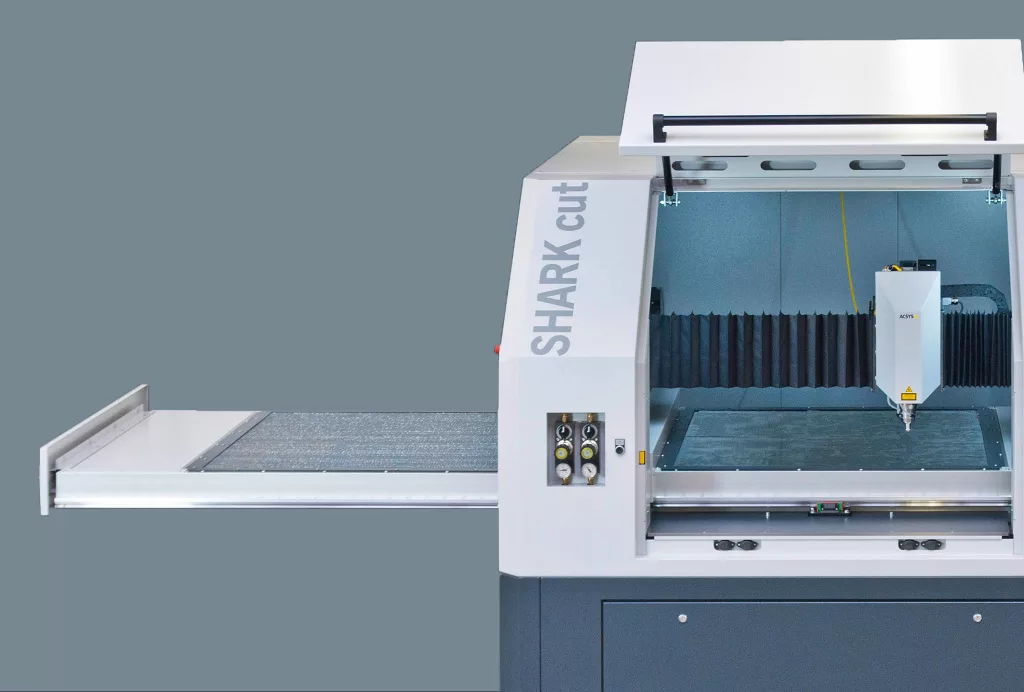

For laser cutting over longer distances, you need a system that has enough space for your workpieces and the necessary robustness for precise processing. Just like the SHARK®: The innovative laser cutting center from ACSYS accepts sheet metal in formats up to 1,250 mm × 1,250 mm and processes workpieces precisely and vibration-free. The result is precision contours of excellent quality.

The power of precision lies in calm.

Generous interior space, compact system dimensions, high flexibility and speed: the SHARK® scores with precisely these strengths. Above all, however, the system impresses with its reliably high precision in industrial use. This is guaranteed by the low-vibration machine bed made of granite. It gives the system the necessary calmness for cutting precise contours. This makes the SHARK® a highly specialized laser cutting center for demanding tasks.

SHARK® cut

Cutting

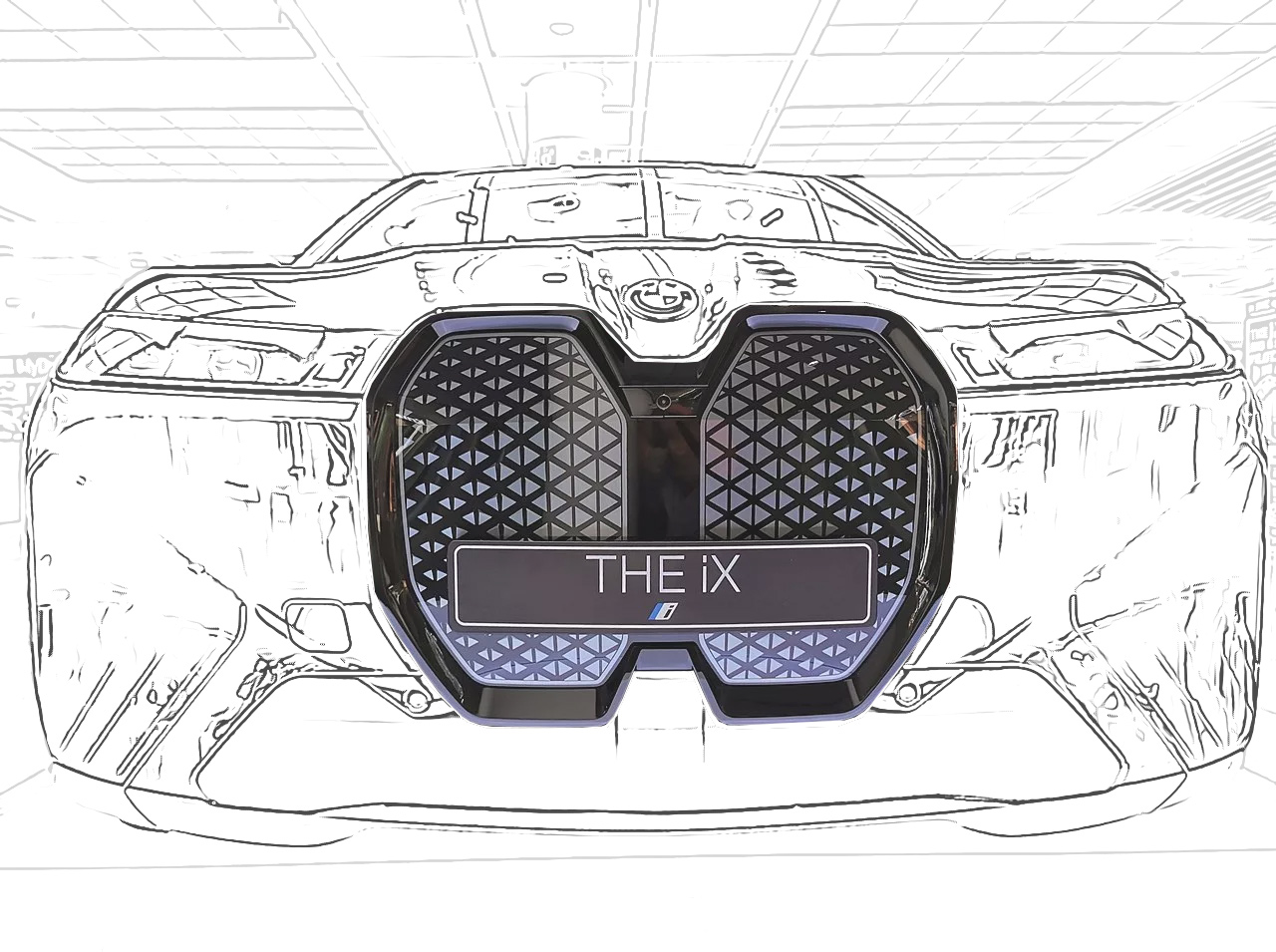

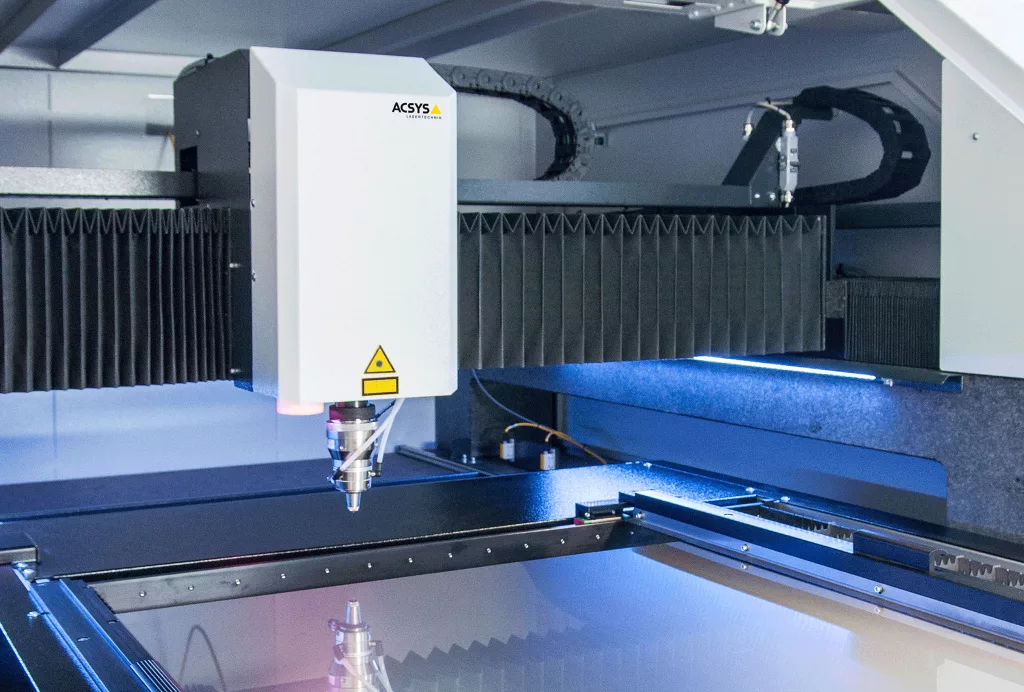

The SHARK® cut is the ideal choice for precise laser cutting in an industrial environment. In addition to the heavy granite machine bed, other precision technologies such as automatic distance control and highly dynamic linear motors ensure this. The latter also guarantee above-average processing times. The SHARK® cut is not only designed for speed and precision. The laser cutting center also impresses with its versatility with regard to different workpiece sizes and geometries. Sheets with a surface area of up to ~1.56 m² (1,250 mm × 1,250 mm) are easy pickings for the SHARK® cut in classic laser cutting. In addition, a program-controlled dividing head can be used as a fourth rotary axis and with a manually adjustable fifth axis for interpolated laser cutting. This enables the processing of round components.

In combination with the appropriate ACSYS software, there are virtually no limits to the processing possibilities. Whether inlays, templates or high-precision cut parts: With AC-Laser, the laser software suite from ACSYS, you as a user can achieve first-class results in all disciplines. If required, additional functions such as the Live Adjust System (LAS cut) – the innovative camera system for laser cutting applications – can be added. It shows you the usable processing area on the screen and allows you to precisely position the cutting layout. For fewer rejects and higher material yields with massively reduced set-up times.

Add-on technologies for specific requirements

SHARK® laser cutting systems are designed for precision and efficiency as standard. That’s what makes them so economical. We offer you a broad and technologically unique portfolio of options so that you can benefit even if your machining requirements are anything but standard. You will find a solution for almost every requirement and can put together your own individual SHARK®.

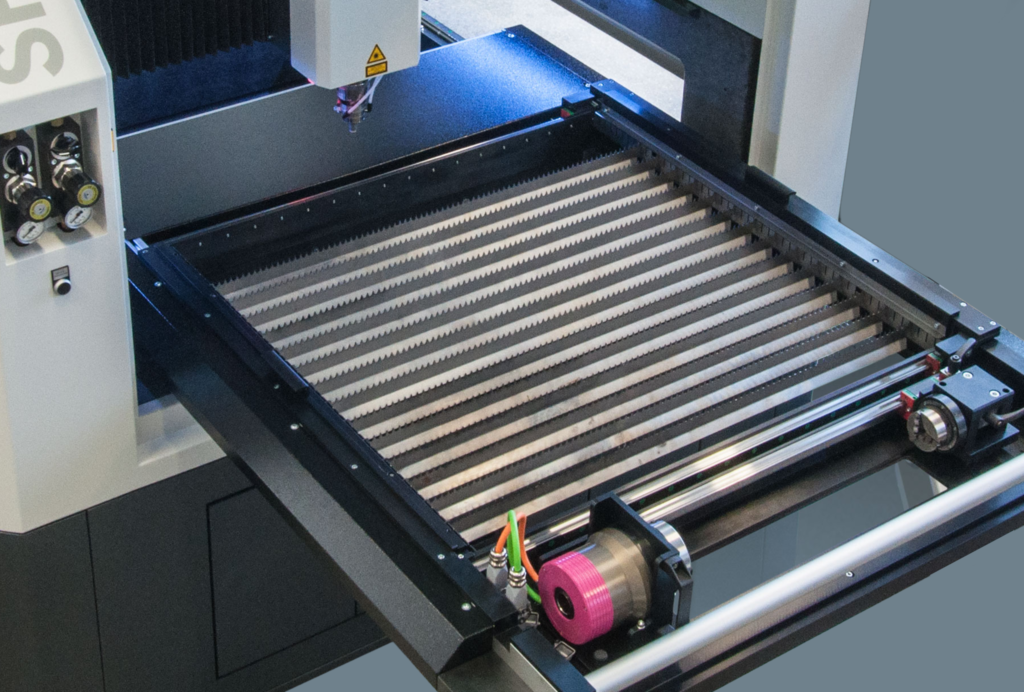

Cutting Table

Front drawer

Component and workpiece drawers allow components to be fed into and out of the laser system safely and accurately. ACSYS drawer systems also score points with improved ergonomics and increased flexibility in workpiece handling. The load capacity of the front drawer varies depending on the machine type and equipment.

Interchangeable drawer

To reduce set-up times and to load the laser cutting system parallel to production time, the exchangeable drawer is an option to increase performance. Finished lasered workpieces can be ejected and new workpieces set up in a single process step.

Cutting Table Board

Cutting table boards specifically adapted to the processing result, material type and thickness ensure optimum results during laser processing. While a honeycomb cutting board with its honeycomb structure guarantees optimum flatness, improves air circulation and minimizes reflections, a lamella cutting board with its parallel steel lamellas is particularly suitable for heavy and large objects as well as for plastics and composite materials. The lamella structure reduces vibrations and at the same time ensures easy cleaning and maintenance as well as a high degree of flexibility in material processing. Steel slats are particularly strong and can be replaced cost-effectively when worn.

DFC cut – Dynamic Focus Control

Dynamic Focus Control (DFC cut) ensures that the optimum energy is always generated at the focal point of the lens during laser cutting and laser fine cutting. For this purpose, the laser focus is constantly and dynamically monitored and tracked so that even the finest surface differences have no effect on the cutting result. In addition, free-form surfaces can be processed in this way without optical distortion or compromising on quality.

Dividing Head cut

The CNC-controlled precision dividing head is optimized for exact laser cutting and offers particularly high flexibility in terms of the size and scope of the workpieces to be cut. For processing round components, the software-controlled dividing head cut can be used as a fourth rotary axis and manually adjustable fifth axis for interpolated laser cutting.

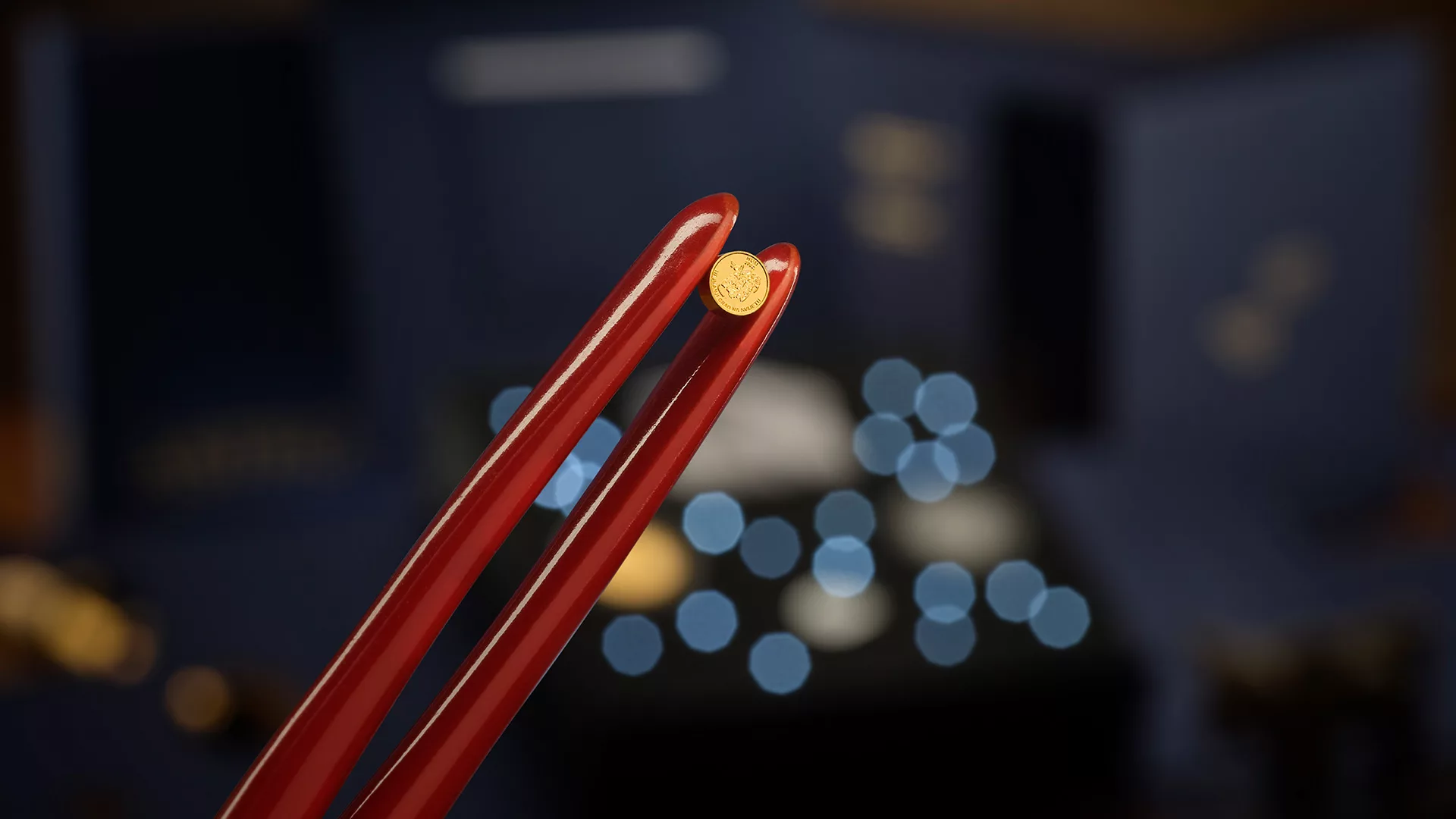

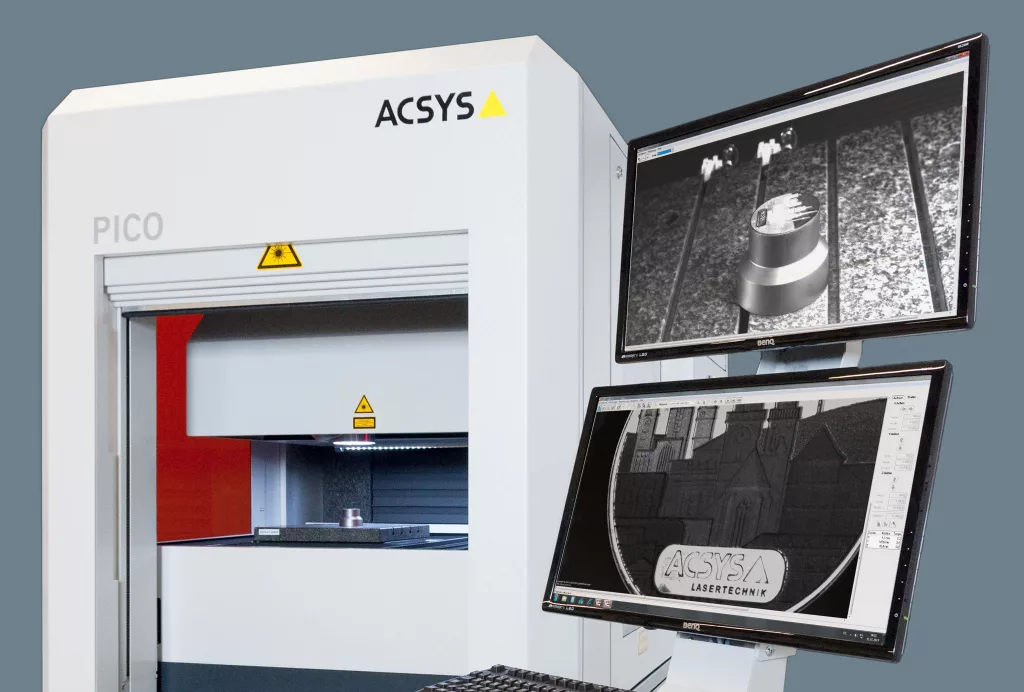

LAS cut – Live Adjustment System cut

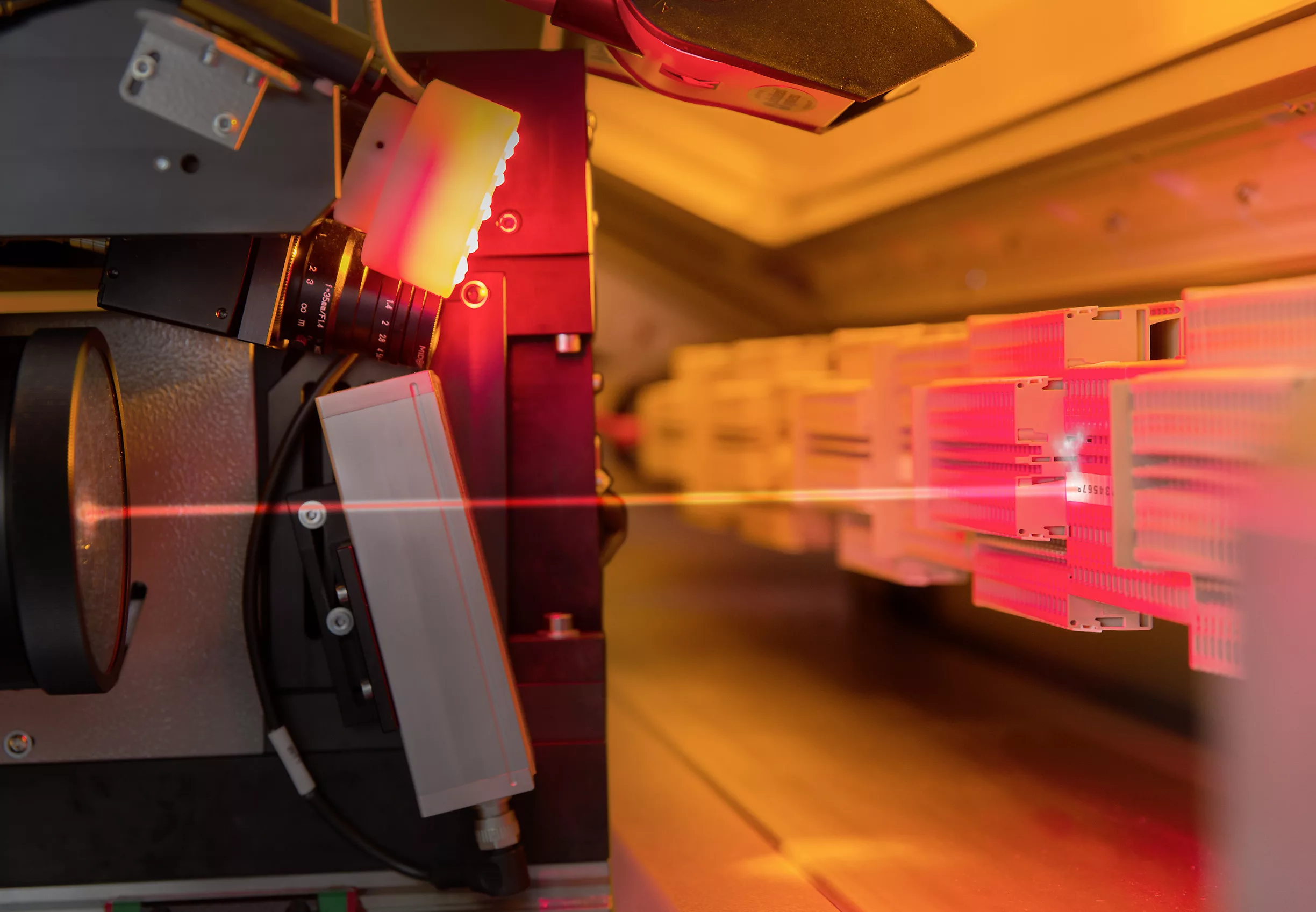

The camera-supported Live Adjustment System cut significantly reduces your set-up effort and enables the exact positioning of even the smallest workpieces in the system. The principle: a high-resolution camera transmits images directly from the interior to the monitor on the control panel. With the help of the infinitely variable digital zoom function, you can bring all the details of a workpiece onto the screen and place layouts with absolute precision. The target result is displayed as a preview. If required, new layouts, markings, barcodes or data matrix codes can even be created and implemented directly on the monitor – without additional workpiece measurement.

The LAS cut is also available as a dual camera system for the highest precision requirements. The first camera shows an image of the workpiece inserted for processing. This is the basic LAS function. The second camera provides a view directly through the beam path of the laser and delivers a high-resolution partial image of the workpiece region to be processed.

Smart software solutions for optimal results

ACSYS’ own software enables you to fully exploit the potential of your laser systems. In addition to numerous functions for controlling the laser processes and for automation, our software offers a wide range of interfaces and customization options, adapted to your individual requirements on request. The user-friendly interface is easy to operate and provides a wealth of information and functions for optimizing the laser process.

AC-LASER

Achieve outstanding results with the powerful modules of the AC-LASER software. Thanks to the graphical user interface, you can implement any requirement in the shortest possible time without having to compromise on design or quality. Intelligent image processing functions reduce set-up times to a minimum.

The AC-LASER software enables productivity without compromise. The close integration and uniform functionality of different modules enables you to consistently implement your ideas and requirements.

Performance features

- Camera image

The LAS – Live Adjust System enables precise positioning of even the smallest workpieces.

- Multi-axis functions

Up to 7 controlled axes can be moved simply at the click of a mouse or fully automatically.

- 3D functionality

Extensive processing options for 3D engraving with integrated depth control and digitizing functions.

- Special programming

Customer-specific layout and sequence programming as well as database connections.

- Professional text layout tools

Line spacing, spacing and typeface changes can be programmed and modified with any font installed on Windows.

- Material parameter wizard

Simple search for suitable laser parameters for a wide range of materials. Automatic creation of a parameter scale from data in an extensive parameter database.

- Barcode and DataMatrix code

Comprehensive processing module for barcodes and DataMatrix codes.

- Dual laser control

The software can manage and control two laser sources in parallel.

- Split layout

Intelligent segmentation. Large-area engravings on flat or round parts are “intelligently” separated and optimized.

- Multiple Execution

Intelligent batch processing. The laser machine can control its tasks fully automatically overnight or at weekends and process several blanks automatically.

Custom Programming

Do you need to integrate third-party software? Or do you need to connect databases or spreadsheets live? Our in-house developed software allows a wide range of customizations, from cloud connection to machine-to-machine communication with OPC/UA.

Exploit the full potential of your ACSYS laser system with our customizable software. In addition to numerous functions for controlling the laser processes and for automation, we offer you customized interfaces and customer-specific programming.

LAS – Live Adjustment System

Our unique Live Adjustment System (LAS) is just one example of how ACSYS intelligently combines hardware and software. Only with a powerful software solution can machine vision be turned into recognition. The camera-supported Live Adjustment System significantly reduces your set-up effort and enables the exact positioning of even the smallest workpieces in the system.

The principle: a high-resolution camera transmits images directly from the interior to the monitor on the control panel. With the help of the infinitely variable digital zoom function, you can bring all the details of a workpiece onto the screen and place layouts with absolute precision. The target result is displayed as a preview. If required, new layouts, markings, barcodes or data matrix codes can even be created and implemented directly on the monitor – without additional workpiece measurement.

Material Parameter Wizard

The material parameter wizard makes it easy to search for suitable laser parameters for a wide range of materials. The automatic creation of a parameter scale on the respective material and the subsequent adjustment in the software quickly and easily lead to the best results.

Automation, laser system & software: everything from a single source

At ACSYS, we combine hardware, software, processes and automation to create integrated solutions for your success. And because we not only manufacture systems, but also supply the software to go with them, we can tailor processes and complete turnkey-solutions perfectly to your needs and challenges. With our wide range of automation options, you can make your laser process more efficient. It does not matter whether a robot feed, a rotary indexing table, a system interlinking or another automation solution is required.

Conveyor technology

Laser systems from ACSYS can be seamlessly integrated into existing conveyor systems. Through intelligent interlinking, throughput times can be optimized and processes made more efficient. In addition, an optimized material flow through precisely coordinated conveyor systems and handling technology ensures less space is required and conveying capacities are increased.

From the safe and effective transportation of your workpieces to perfectly orchestrated hardware and software processes: ACSYS supplies turnkey conveyor technology in conjunction with innovative laser systems from a single source.

Pallet handling

The automatic stacking and destacking of palletized workpieces saves a great deal of time in the process sequence. ACSYS laser systems can be combined with various picking systems to handle pallets fully automatically, safely and effectively. For example, two pallet towers ensure that unprocessed workpieces are stacked from one side and fed into the laser process, while finished parts are stacked on the other side for removal. Depending on your requirements and processes, we will work with you to find the ideal pallet handling solution to integrate precise and efficient laser processing into your production process.

Success stories “Made by ACSYS”

Your personal contact

Do you have any questions?

I am happy to help.

Isabell Richter

Reception

Telephone: +49 7154 80875 0

E-Mail: info@acsys.de