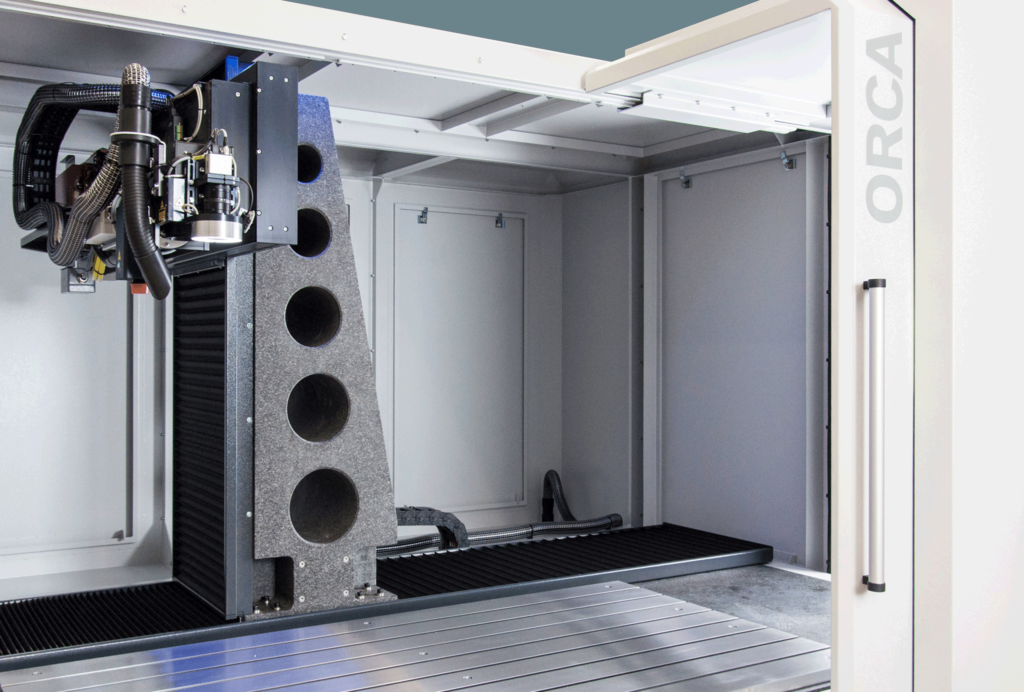

Plenty of space. All possibilities.

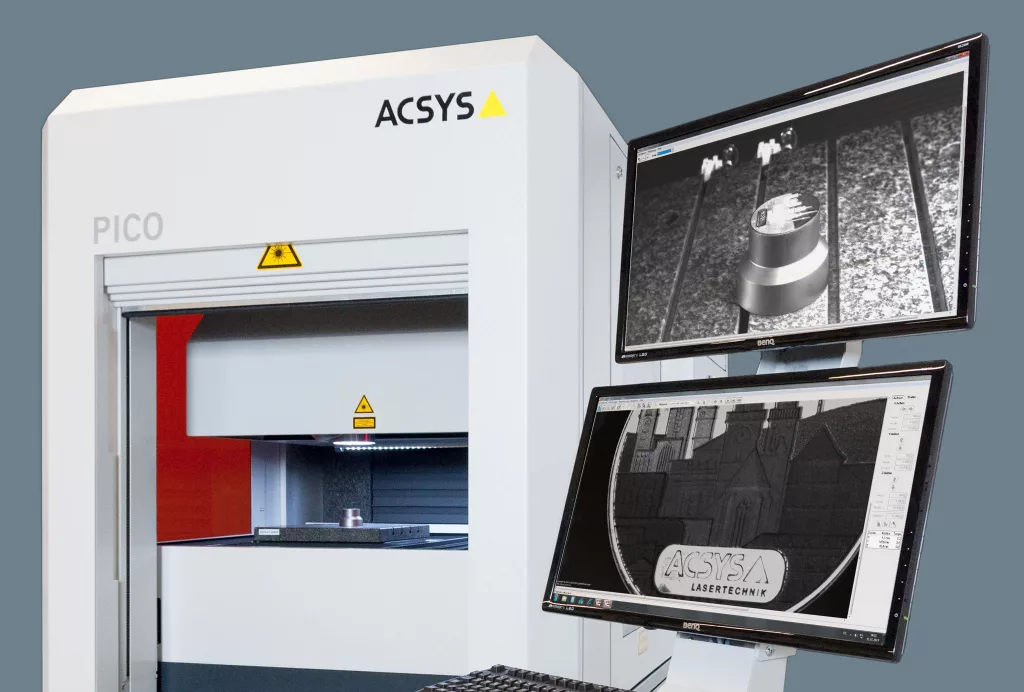

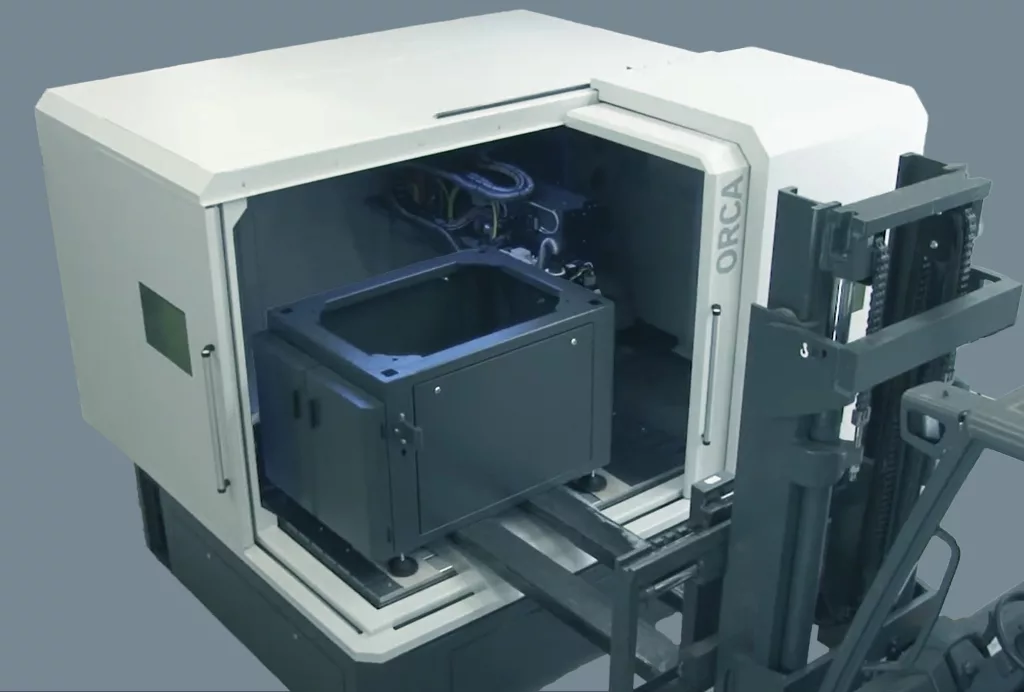

How can you now apply markings or engravings to solid workpieces with micrometer precision? Quite simply and economically with the ORCA® large-capacity laser center – the largest series-produced laser processing system from ACSYS. Our engineers have thought of everything in the design, even around corners. This is demonstrated by the innovative door concept: a solution with doors that open wide over the corner so that the ORCA® can also be easily loaded with large and bulky workpieces using a forklift or crane.

Precision in all dimensions

One of the strengths of the ORCA® is precise laser processing in all dimensions – for both small and larger-than-average workpieces. With a processing area of 2,900 mm × 1,000 mm, the system offers an impressive amount of space. Agility included, because with the ORCA® up to five NC-controlled axes ensure maximum dynamics and flexibility during laser processing.

ORCA®

Engraving, marking, structuring, welding

ORCA® is the perfect solution for all workpieces that are heavy, large or simply bulky and need to be processed precisely by laser. Whether engraving, marking, structuring or welding: ORCA® masters all of these laser processes if required and impresses with its high precision and repeat accuracy – even with bulky components and multi-sided processing. This is guaranteed by the stable construction of the machine body and a machine bed including a granite traveling column. Another special feature: The ORCA® is equipped with a movable control panel so that the extra-wide door opening can be fully utilized and the machine can be worked on optimally. It is simply moved to the side as required.

The laser processing system is even more flexible in technical terms. Not only individual components, but also palletized workpieces can be processed highly efficiently. There are also numerous ACSYS options for even higher processing requirements if required. For example, the camera-supported Live Adjustment System, or LAS for short. It enables precise positioning of the workpieces and thus ensures consistently perfect results.

Another highlight is the optional electrically swiveling galvo head. It can be positioned manually or software-controlled from horizontal to vertical – steplessly, so that the laser can process even complex workpieces on several sides in a single operation.

Add-on technologies for specific requirements

The ORCA® large-capacity laser center is designed as standard for precision with large, heavy and bulky workpieces. As standard, the ORCA® offers everything you would expect from a modern laser processing system. If your machining requirements are anything but standard, we offer you a portfolio of options that is as broad as it is technologically unique. You will find a solution for almost every requirement and can customize your ORCA®.

All-in-One Quick-Change System

A high-precision laser system solution for three completely different laser processes: The patented quick-change system from ACSYS enables marking, engraving and cutting with laser technology. The laser is guided by a galvanometer scanner and either gravure optics (F-theta, plane field optics, telecentric optics) or a laser cutting head is attached.

DFC – Dynamic Focus Control

The DFC module from ACSYS ensures that the laser focus is constantly and dynamically tracked on curved components. This saves you the time-consuming task of splitting the layout into different focus layers. What’s more, even complex 3D geometries can be processed precisely with the dynamic focus control. Reductions in processing quality are a thing of the past.

DFS – Double Focusing System

With the Double Focusing System (DFS), you can see at a glance whether the laser processing head is at the correct focus distance from the workpiece. The correct focus distance can be determined in this way, especially for surfaces that are difficult to access or difficult to measure.

A pilot laser marks the center of the laser processing field and also offers the advantage that either fitting rectangles or the contour lines of the layout can be displayed directly. A high-resolution camera transmits images directly from the interior to the monitor on the control panel. The Double Focusing System is also available with green laser systems.

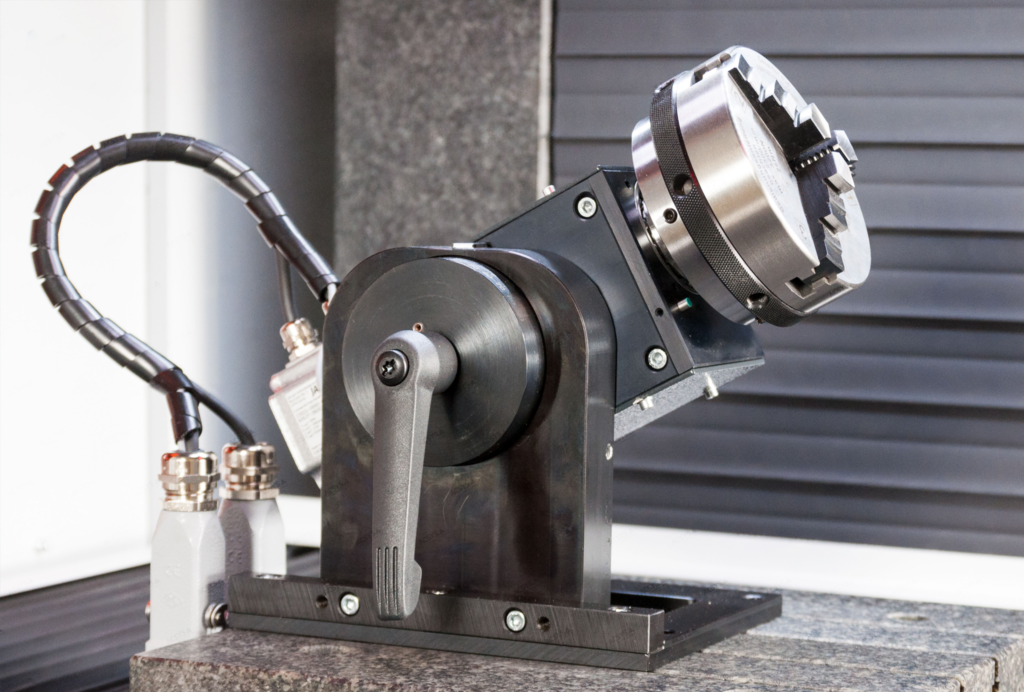

Dividing Heads

ACSYS offers you various dividing heads for precise angular positioning and further turning of workpieces. Each of the devices is NC-controlled and has an electric rotary axis as well as a manually or electrically adjustable swivel axis. Dividing heads are used for the internal and external marking of rings and cylindrical or conical workpieces. They are available with manual feed or automatic feed with automatic loading.

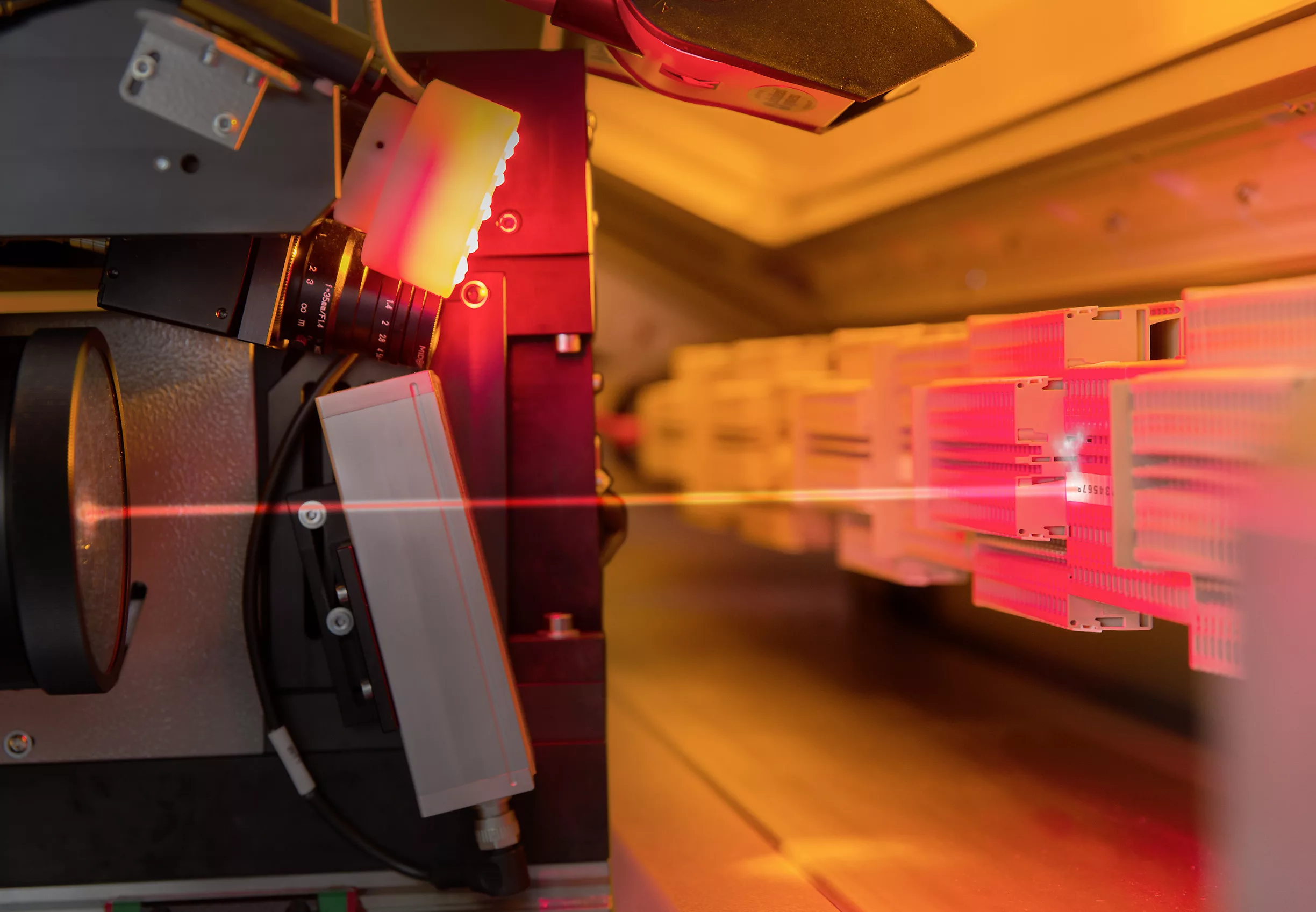

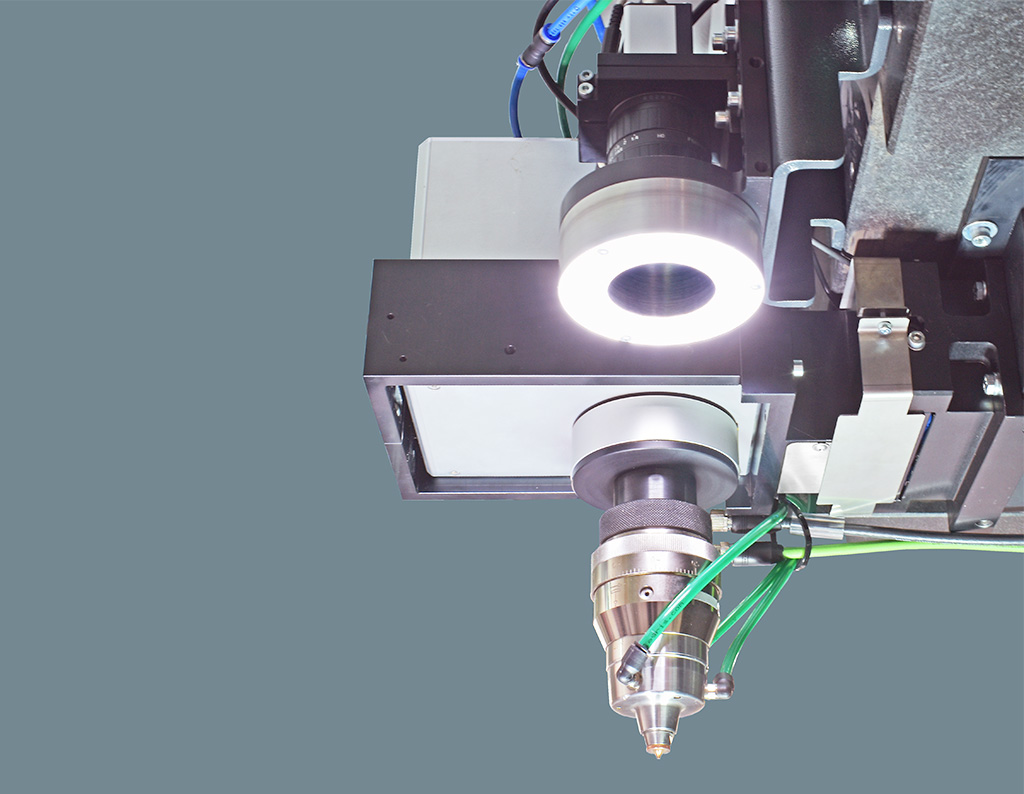

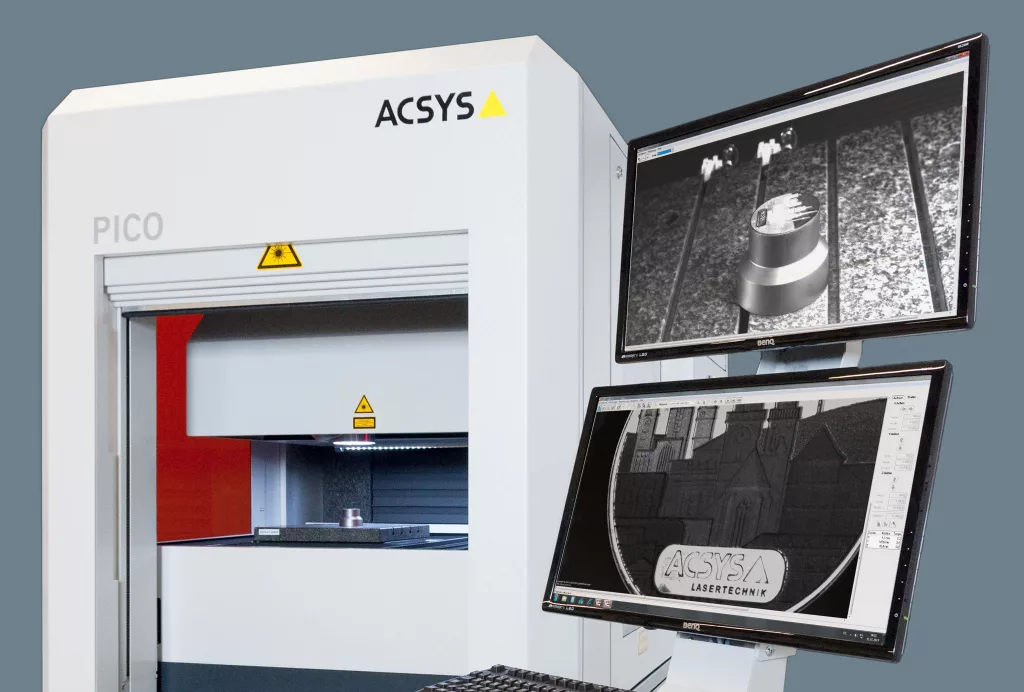

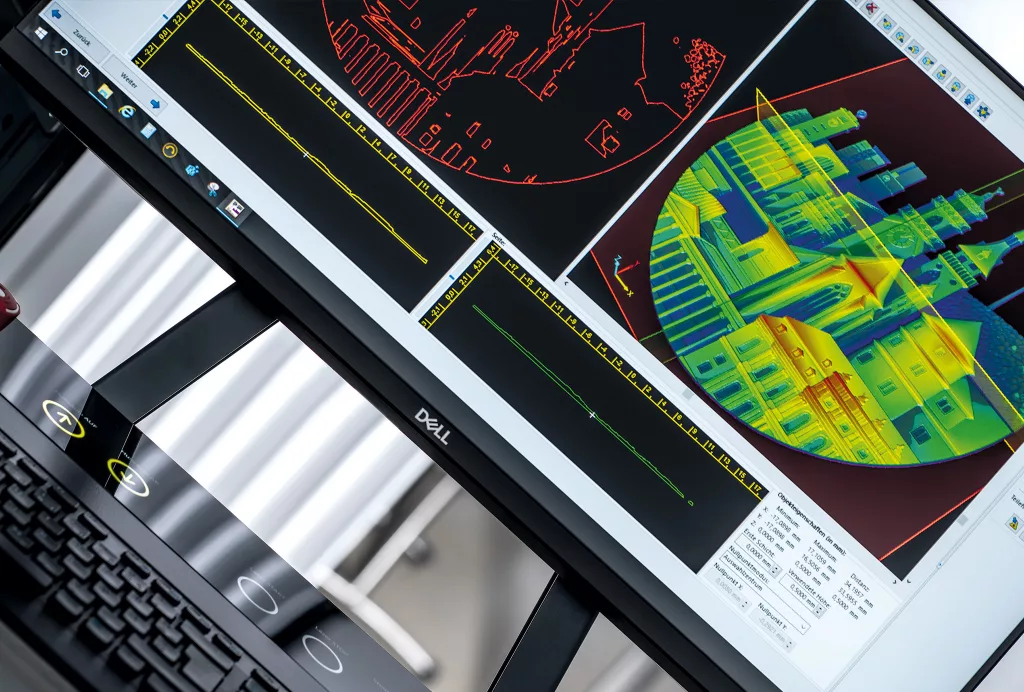

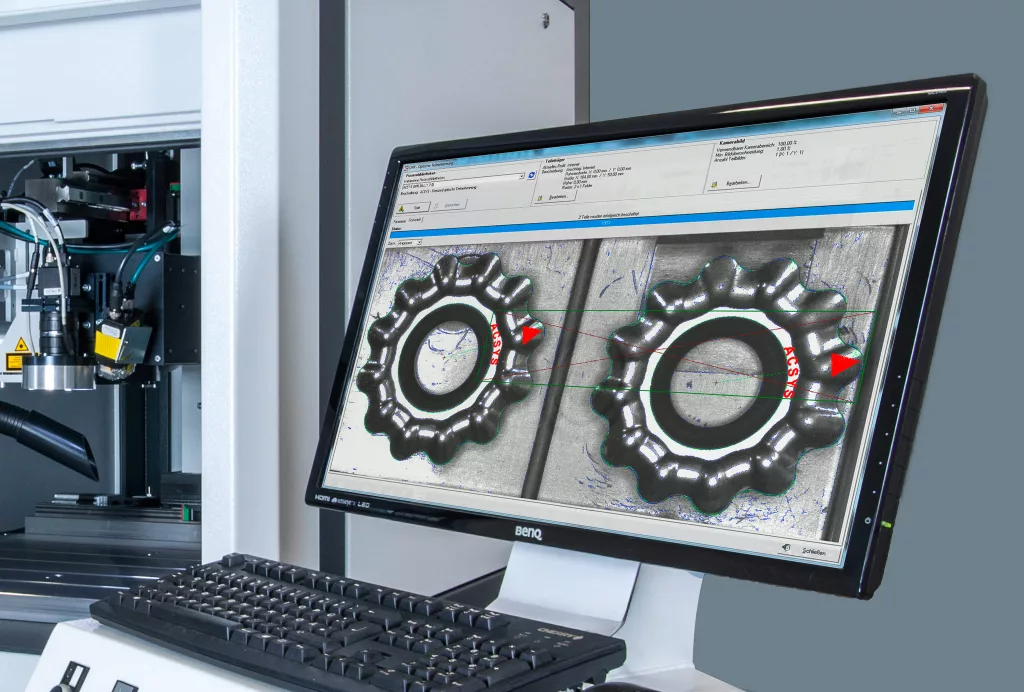

LAS – Live Adjustment System

The camera-supported Live Adjustment System significantly reduces your set-up effort and enables the exact positioning of even the smallest workpieces in the system. The principle: a high-resolution camera transmits images directly from the interior to the monitor on the control panel. With the help of the infinitely variable digital zoom function, you can bring all the details of a workpiece onto the screen and place layouts with absolute precision. The target result is displayed as a preview. If required, new layouts, markings, barcodes or data matrix codes can even be created and implemented directly on the monitor – without additional workpiece measurement.

The LAS is also available as a dual camera system for the highest precision requirements. The first camera shows an image of the workpiece inserted for processing. This is the basic LAS function. The second camera provides a view directly through the beam path of the laser and delivers a high-resolution partial image of the workpiece region to be processed.

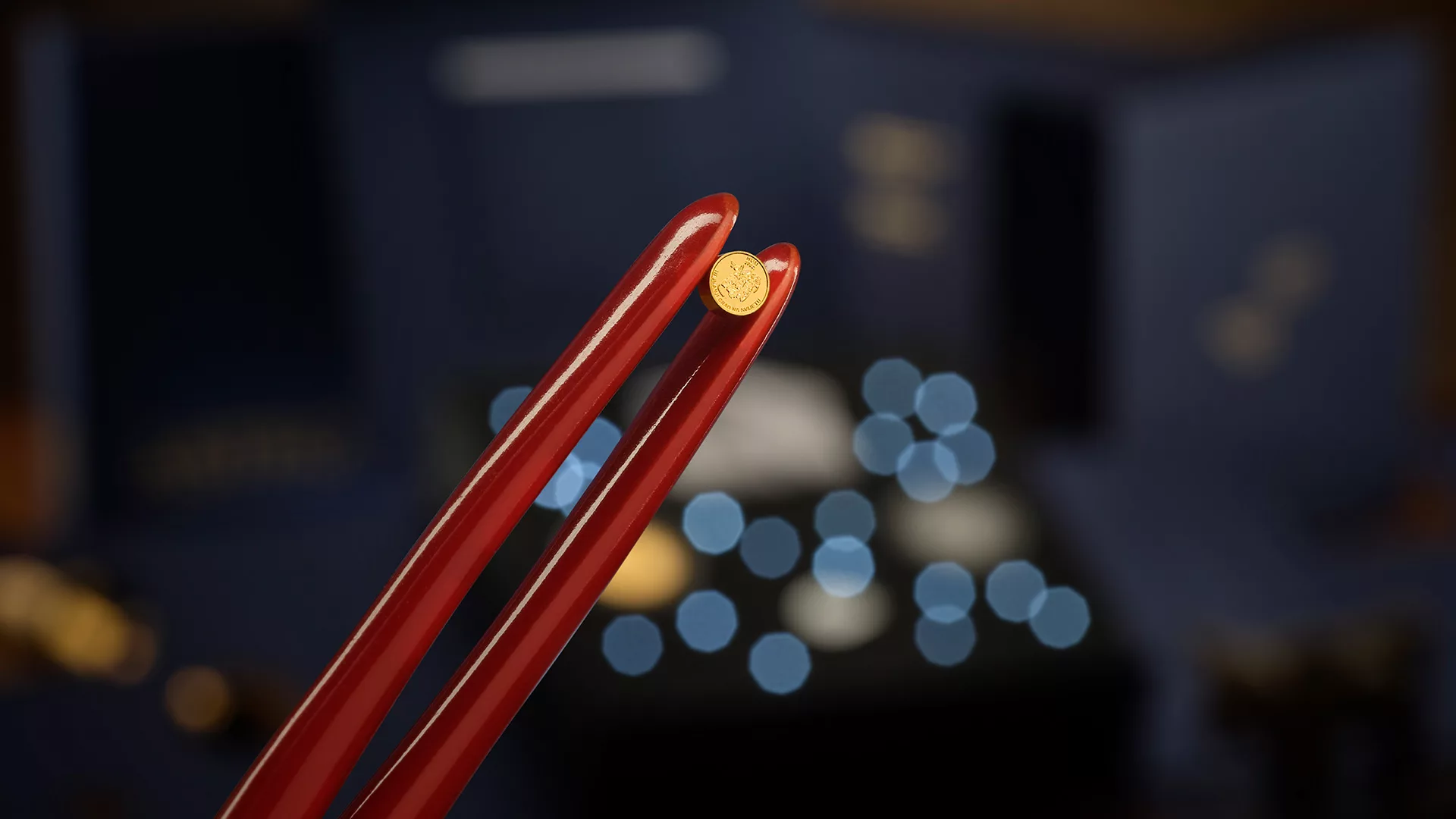

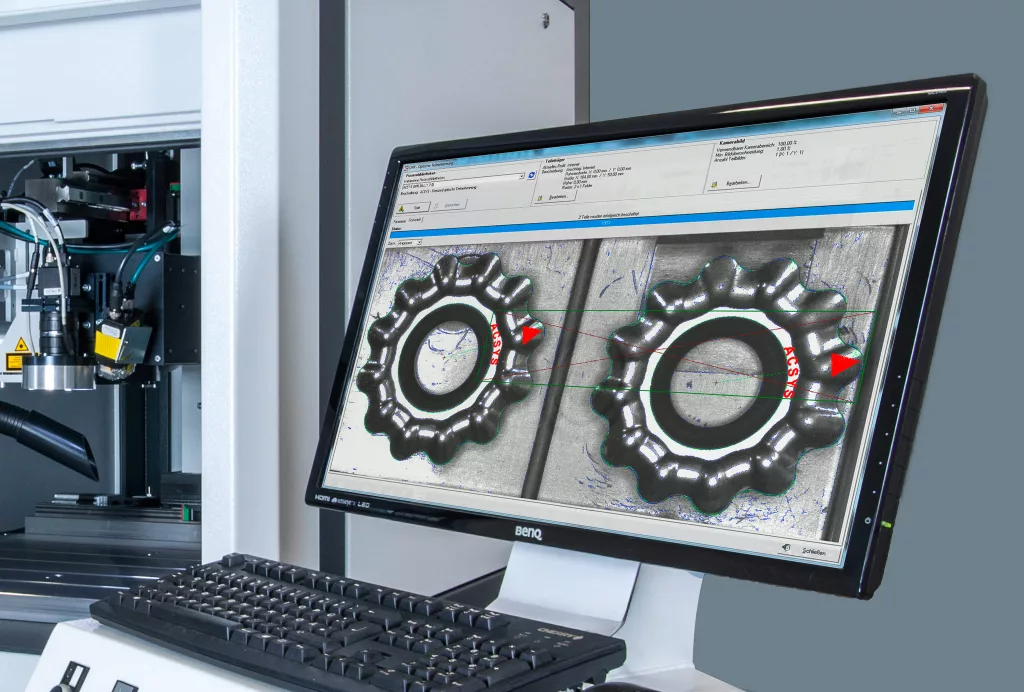

OPR – Optical Parts Recognition

Optical part recognition from ACSYS is the key to highly efficient batch processing. The system is ideal if you feed several workpieces of the same type to your ACSYS system in bulk at the same time in order to process them in a single pass. How it works: The OPR camera module captures the parts on the workpiece carrier. The associated software uses the images to recognize the position and alignment of each individual workpiece and controls the laser so that the engravings or markings are always made exactly at the predefined position.

PLD – Pilot Laser Module

The Pilot Laser Module (PLD) generates a visual pointing laser that makes it much easier to position the workpiece correctly under the laser processing head. The clearly visible red light beam of the pilot laser offers several advantages: On the one hand, it marks the center of the laser processing field and also indicates a fitting rectangle according to the layout specification. Optionally, the fitting rectangles of all layout elements and, in the case of small layouts, the contour lines of the layout can also be displayed directly.

And with the help of the AC-LASER software, reference points and cutting edges can be precisely traced, allowing the laser process to be simulated before actual processing. In this way, the accuracy can be checked in advance and, if necessary, adjusted and simulated again without consuming material.

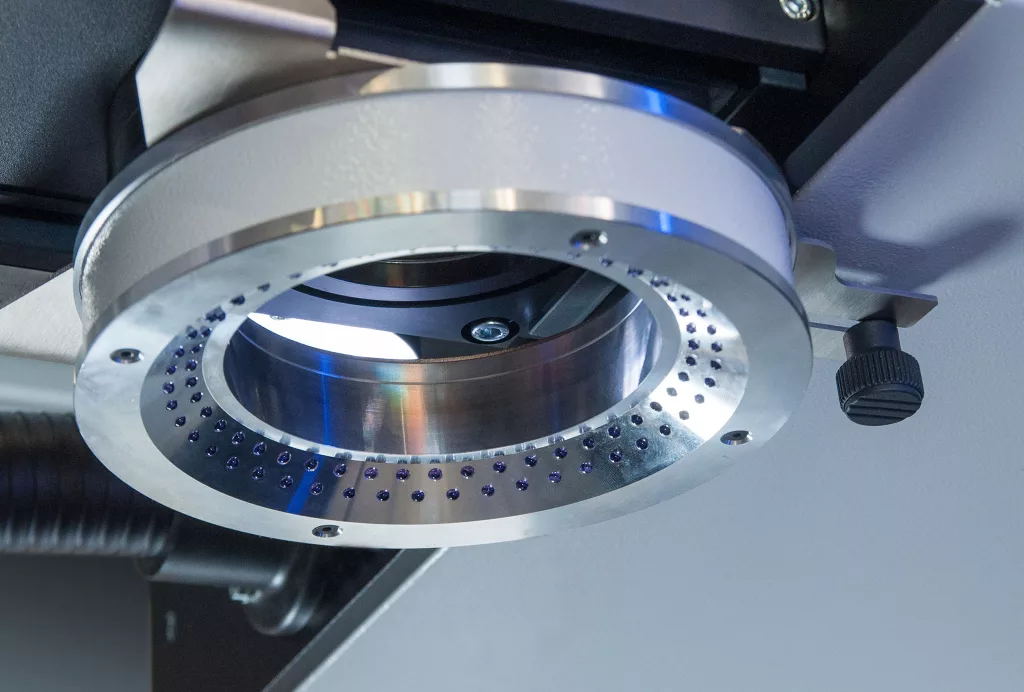

Quick Lens Changer

Demanding applications require the lens or optics to be changed for high-precision laser processing. With the quick lens changer from ACSYS, quick and easy changing when using different processing optics is child’s play. And the AC-LASER software ensures that all parameters are set correctly straight away – no matter how often you have to change the lens. The smart quick lens change system from ACSYS ensures consistently high-quality precision machining of the workpieces and maximizes efficiency in the production process.

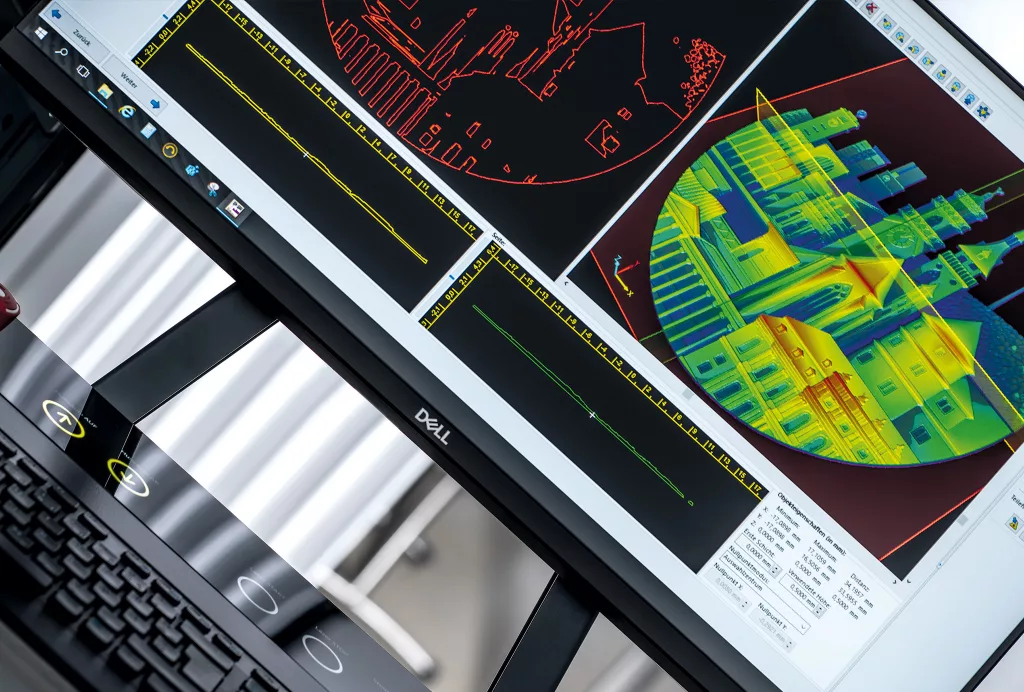

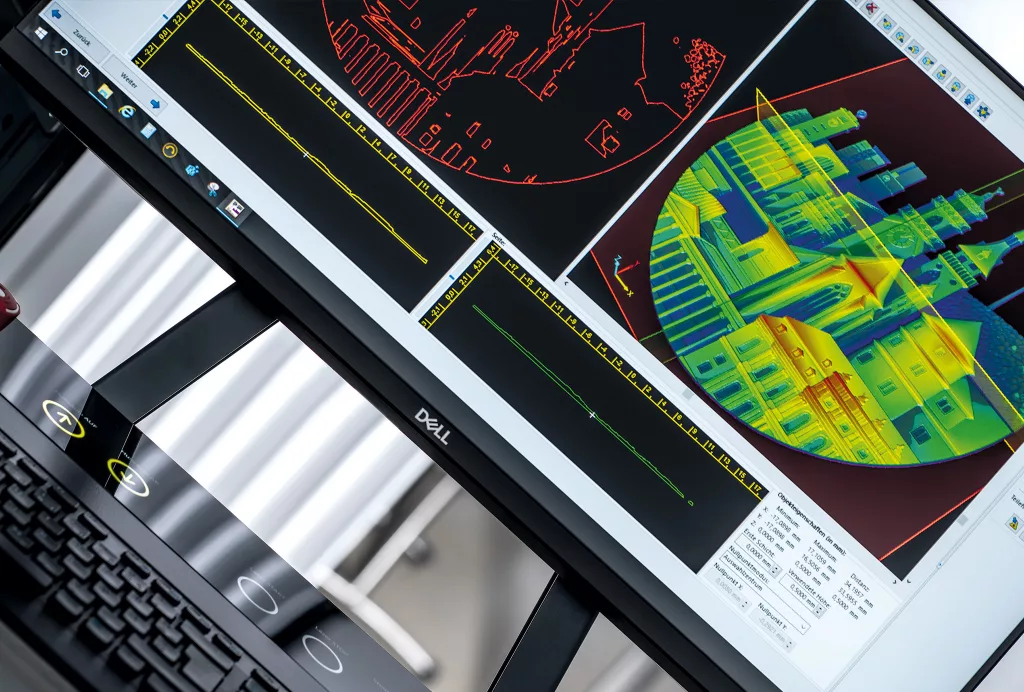

RAS – Rapid Area Scan

With the unique Rapid Area Scan process, you can speed up the high-precision digitization of templates for the creation of 3D models by up to 30 times – including the transfer of data to CAD tools. Instead of a single measuring point, a complete measuring line is projected. This means that an original can be scanned in blocks and significant time savings can be realized during the scanning process. The scanned segments are merged by the software without any loss of quality. The line width can also be adjusted flexibly and easily. And with the precise preview of the scan, you have full control.

The Rapid Area Scan System can be integrated into all ACSYS precision laser systems of the µ series – also as a retrofit. And the direct interface to tools such as CarveCo saves even more time. RAS also offers the great advantage of scanning and processing in one system.

Smart software solutions for optimal results

ACSYS’ own software enables you to fully exploit the potential of your laser systems. In addition to numerous functions for controlling the laser processes and for automation, our software offers a wide range of interfaces and customization options, adapted to your individual requirements on request. The user-friendly interface is easy to operate and provides a wealth of information and functions for optimizing the laser process.

3D Assistant

The 3D assistant makes it easy to create complex 3D and micro-engravings. A graphic preview makes it easier to set up the workpiece. Thanks to automated readjustment of the laser focus, even very deep 3D engravings can be realized in top quality. A very high surface quality is achieved through the targeted parameterization of the laser.

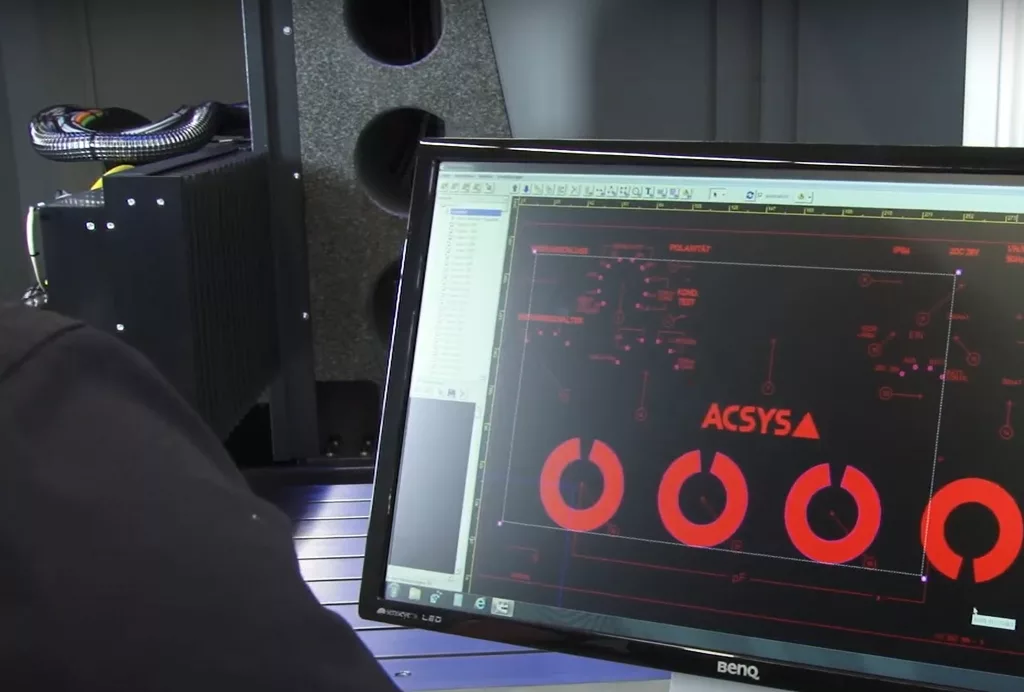

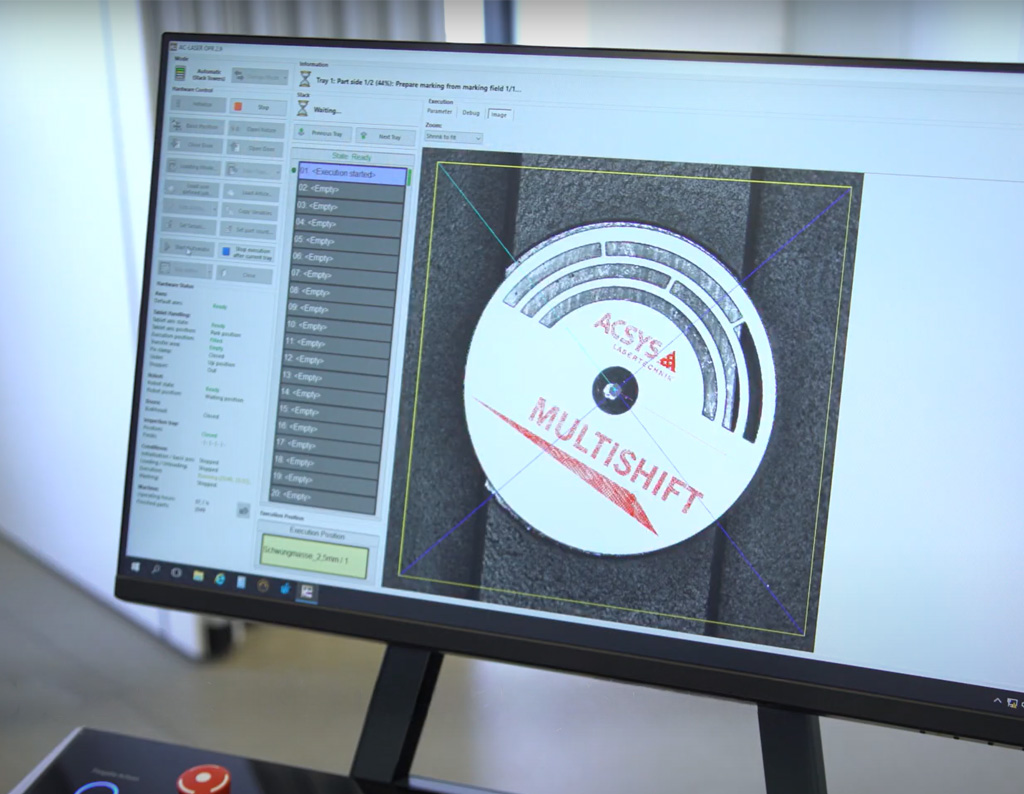

AC-LASER

Achieve outstanding results with the powerful modules of the AC-LASER software. Thanks to the graphical user interface, you can implement any requirement in the shortest possible time without having to compromise on design or quality. Intelligent image processing functions reduce set-up times to a minimum.

The AC-LASER software enables productivity without compromise. The close integration and uniform functionality of different modules enables you to consistently implement your ideas and requirements.

Performance features

- Camera image

The LAS – Live Adjust System enables precise positioning of even the smallest workpieces.

- Multi-axis functions

Up to 7 controlled axes can be moved simply at the click of a mouse or fully automatically.

- 3D functionality

Extensive processing options for 3D engraving with integrated depth control and digitizing functions.

- Special programming

Customer-specific layout and sequence programming as well as database connections.

- Professional text layout tools

Line spacing, spacing and typeface changes can be programmed and modified with any font installed on Windows.

- Material parameter wizard

Simple search for suitable laser parameters for a wide range of materials. Automatic creation of a parameter scale from data in an extensive parameter database.

- Barcode and DataMatrix code

Comprehensive processing module for barcodes and DataMatrix codes.

- Dual laser control

The software can manage and control two laser sources in parallel.

- Split layout

Intelligent segmentation. Large-area engravings on flat or round parts are “intelligently” separated and optimized.

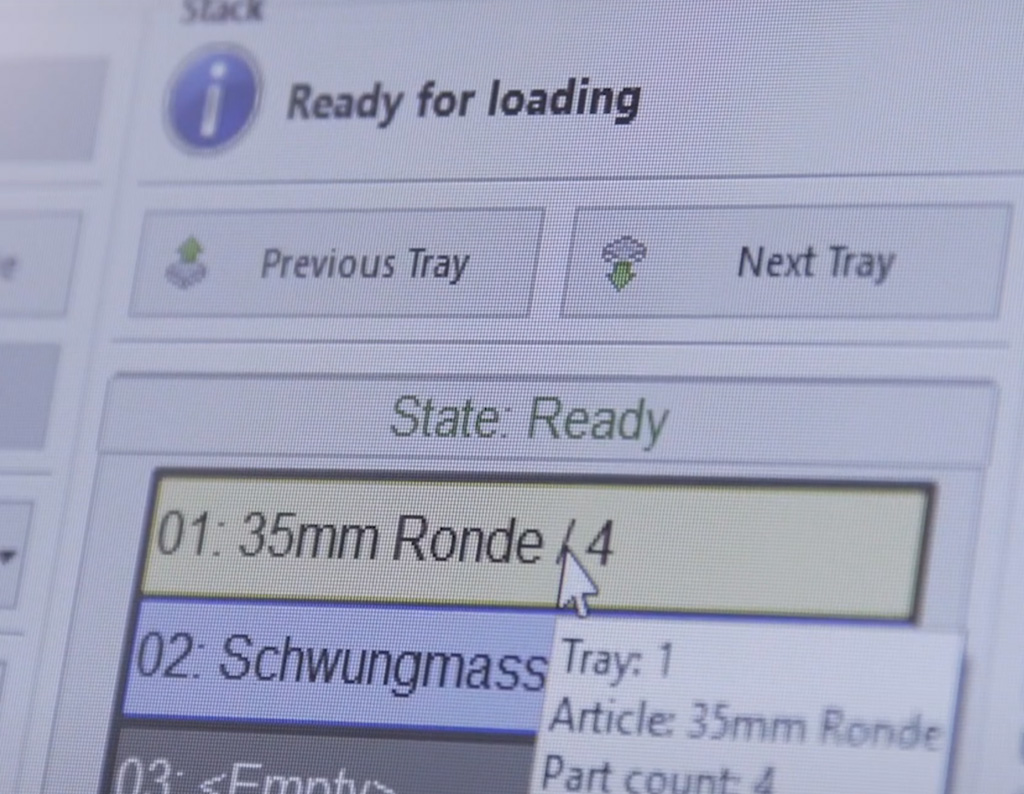

- Multiple Execution

Intelligent batch processing. The laser machine can control its tasks fully automatically overnight or at weekends and process several blanks automatically.

Barcode, DataMatrix & QR code

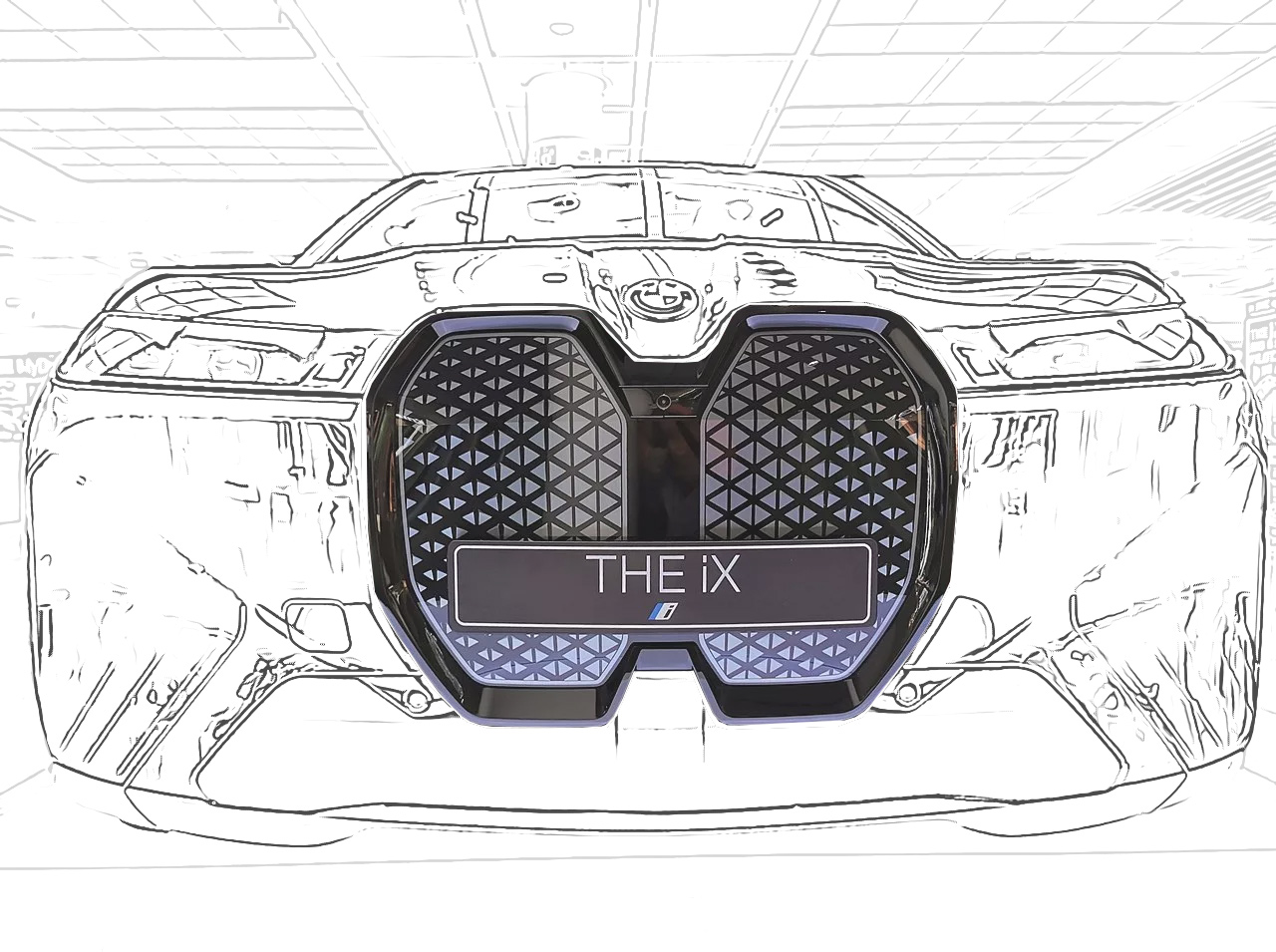

In addition to 1D codes (barcode / barcode), 2D codes such as QR, DataMatrix, Aztec, Code One and dot codes or stacked codes are increasingly being used for marking workpieces. ACSYS offers special software modules for the generation of barcodes, DataMatrix and QR codes, which allow codes to be generated automatically on the fly. Especially when it comes to compliance with ISO 29158, durable and high-quality markings are required, particularly for printed circuit boards, in medical technology or for components in the mobility sector, as well as for the marking of wear tools.

Custom Programming

Do you need to integrate third-party software? Or do you need to connect databases or spreadsheets live? Our in-house developed software allows a wide range of customizations, from cloud connection to machine-to-machine communication with OPC/UA.

Exploit the full potential of your ACSYS laser system with our customizable software. In addition to numerous functions for controlling the laser processes and for automation, we offer you customized interfaces and customer-specific programming.

Database Integration

Whether serial numbers, product markings, data matrix and QR codes or personalization – connecting our laser systems to existing databases is now almost a standard requirement. Thanks to an open database interface, a wide range of database formats from different manufacturers can be connected. In addition to various SQL databases and flat file formats, proprietary database management systems can also be connected to ACSYS laser systems. We will be happy to advise you on the database connection of relational, object-oriented and object-relational databases.

DFC – Dynamic Focus Control

Complex 3D geometries, such as curved components, require the harmonious interaction of powerful hardware and smart software. With the help of Dynamic Focus Control (DFC), the laser focus is constantly and dynamically tracked for curved components, eliminating the need for time-consuming separation of the layout into different focus positions.

LAS – Live Adjustment System

Our unique Live Adjustment System (LAS) is just one example of how ACSYS intelligently combines hardware and software. Only with a powerful software solution can machine vision be turned into recognition. The camera-supported Live Adjustment System significantly reduces your set-up effort and enables the exact positioning of even the smallest workpieces in the system.

The principle: a high-resolution camera transmits images directly from the interior to the monitor on the control panel. With the help of the infinitely variable digital zoom function, you can bring all the details of a workpiece onto the screen and place layouts with absolute precision. The target result is displayed as a preview. If required, new layouts, markings, barcodes or data matrix codes can even be created and implemented directly on the monitor – without additional workpiece measurement.

Material Parameter Wizard

The material parameter wizard makes it easy to search for suitable laser parameters for a wide range of materials. The automatic creation of a parameter scale on the respective material and the subsequent adjustment in the software quickly and easily lead to the best results.

Multiple Execution

Use our intelligent batch processing to control your laser processes fully automatically overnight or throughout the weekend.

With Multiple Execution, you can organize your pending orders reliably, quickly and efficiently. The module monitors the order stock as well as the error-free processing of the process batch.

Small series in particular benefit from the possibilities offered by Multiple Execution for the laser processing of blanks. Intelligent batch processing is an efficient solution for automating production processes, both for automated material feeding and for material handling of finished workpieces.

OPR – Optical Parts Recognition

Software and hardware in perfect harmony: The OPR camera module captures the parts on the workpiece carrier. The associated software uses the images to recognize the position and alignment of each individual workpiece and controls the laser so that the engravings or markings are always made exactly at the predefined position. This makes optical part recognition from ACSYS the perfect solution if you feed several workpieces of the same type to your laser system in bulk at the same time in order to process them in a single pass.

Professional Text Layout Tools

With the help of our convenient layout tools, you can easily combine text, graphics and images to create individual designs. Whether circular texts with individually selectable fonts or different geometric objects and patterns – you have complete design freedom for engraving, marking and structuring your products. And thanks to the intuitive graphical user interface, operation is easy even for inexperienced users.

Split Layout

For particularly large layouts, ACSYS offers smart segmentation for flat and round parts. This allows particularly large workpieces to be engraved, marked and structured using laser technology. For this purpose, the layout is intelligently divided and separated using the split layout technique and then lasered in an approach-optimized manner.

Automation, laser system & software: everything from a single source

At ACSYS, we combine hardware, software, processes and automation to create integrated solutions for your success. And because we not only manufacture systems, but also supply the software to go with them, we can tailor processes and complete turnkey-solutions perfectly to your needs and challenges. With our wide range of automation options, you can make your laser process more efficient. It makes no difference whether a robot feeder, system interlinking or another automation solution is required.

Conveyor technology

Laser systems from ACSYS can be seamlessly integrated into existing conveyor systems. Through intelligent interlinking, throughput times can be optimized and processes made more efficient. In addition, an optimized material flow through precisely coordinated conveyor systems and handling technology ensures less space is required and conveying capacities are increased.

From the safe and effective transportation of your workpieces to perfectly orchestrated hardware and software processes: ACSYS supplies turnkey conveyor technology in conjunction with innovative laser systems from a single source.

Pallet handling

The automatic stacking and destacking of palletized workpieces saves a great deal of time in the process sequence. ACSYS laser systems can be combined with various picking systems to handle pallets fully automatically, safely and effectively. For example, two pallet towers ensure that unprocessed workpieces are stacked from one side and fed into the laser process, while finished parts are stacked on the other side for removal. Depending on your requirements and processes, we will work with you to find the ideal pallet handling solution to integrate precise and efficient laser processing into your production process.

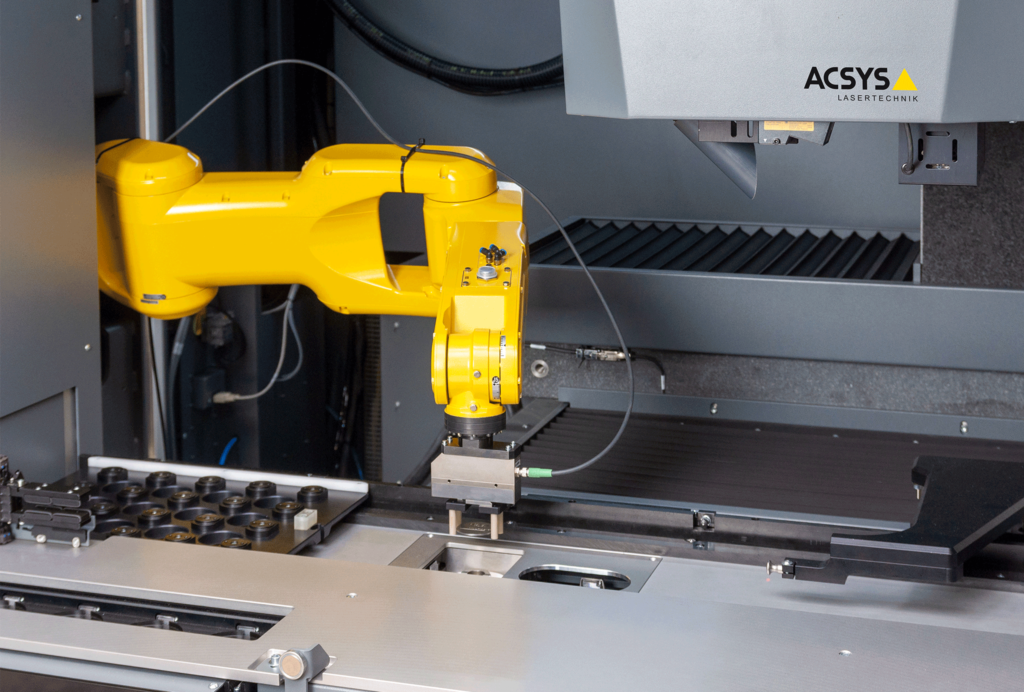

Robots

Intelligent industrial robots ensure efficiency, precision and flexibility. Increase productivity in laser processing and at the same time ensure optimum production results with maximum repeat accuracy. At ACSYS, you benefit from a wide range of different robot systems that we integrate seamlessly into systems and your processes.

Our intelligent robotics solutions offer a wide range of benefits. For example, flexible interfaces such as OPC/UA and sophisticated software functions ensure optimized movements, increased safety and outstanding results in laser processing. Your advantage: hardware, software, integration and service come from a single source and are perfectly coordinated.

See our robot solutions for a wide range of applications and industries for yourself and benefit from the advantages of Industry 4.0 and automation.

Success stories “Made by ACSYS”

Your personal contact

Do you have any questions?

I am happy to help.

Isabell Richter

Reception

Telephone: +49 7154 80875 0

E-Mail: info@acsys.de