Structuring

Process for creating microscopically structured surfaces and new surface properties.

During structuring, the material is melted in a controlled manner using a laser beam and solidified by the process control in such a way that a defined surface structure is created. Structuring can change the optical, mechanical, haptic or biological properties of the processed components. ACSYS laser centers work with pulsed lasers such as innovative Femtosecond Lasers for structuring.

Large field removal: paint removal on large and complex components

Seamless laser processing of components with an area of up to 1,250 mm × 1,250 mm in one piece with the highly developed Large Field Removal technology.

Laser ablation: material removal with laser technology

Laser ablation refers to the removal of material with the help of ultra-short pulsed laser radiation. The process is suitable for high-precision structuring and texturing of surfaces.

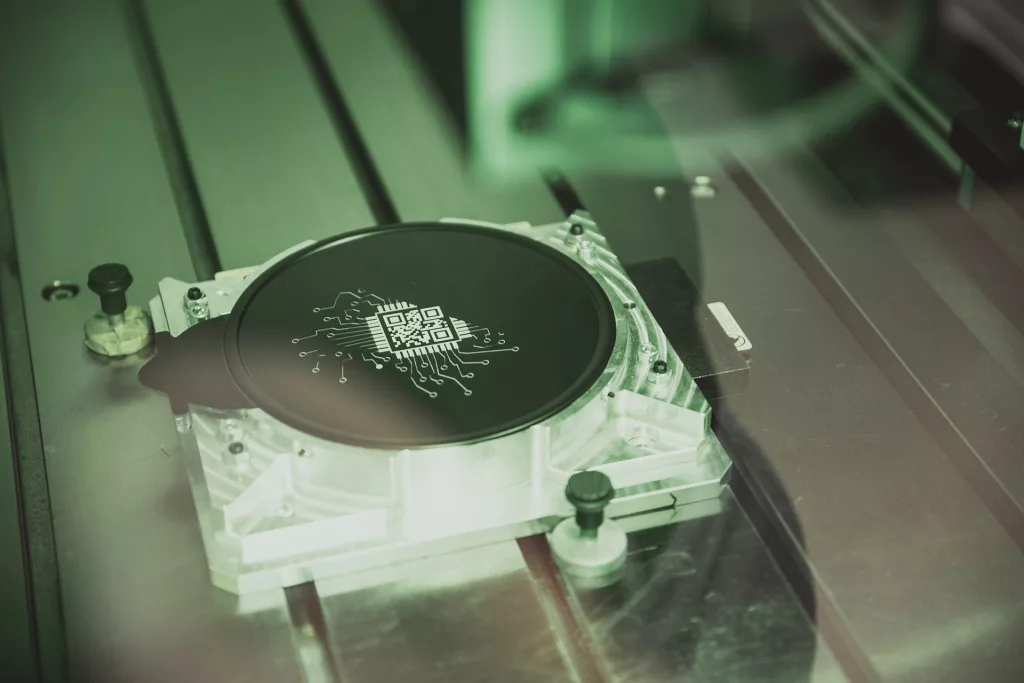

Microstructuring

Microstructuring can be used to create complex 3D geometries and micro- and nanoscale structures on almost any surface. ACSYS uses Femtosecond lasers for this purpose. These allow a pulse duration of less than one picosecond. The heat input is so minimal that even sensitive materials such as plastics, glass, semiconductors or biological tissue can be provided with microstructures.

Surface functionalization

The surfaces of many workpieces can also be specifically functionalized using laser structuring. ACSYS laser systems, for example, use a process called Direct Laser Interference Patterning (DLIP). This creates interference patterns that can improve the adhesion of coatings, increase the corrosion resistance of materials or minimize surface friction.

Laser freezing

Laser freezing is primarily used for the production of polished molding tools such as dies for coin or medal production. It is the alternative of choice to classic frosting, in which a polished surface is partially masked and then sandblasted under a microscope. This is a very complex process, which the laser can perform much faster, more cost-effectively and more precisely.

Polishing / Finishing

With ACSYS Femtosecond Lasers and our patented Pulse Forging® technology, you can make surfaces clean, smooth and shiny – similar to polishing. Neither the material properties nor the hardness of the treated material are changed. In combination with Direct Laser Engraving, precise engravings with filigree gradients and finely polished surfaces are possible without changing tools. Pulse Forging® works more accurately than any other process and smoothes even the smallest structures with a surface accuracy of SA 0.1µm.

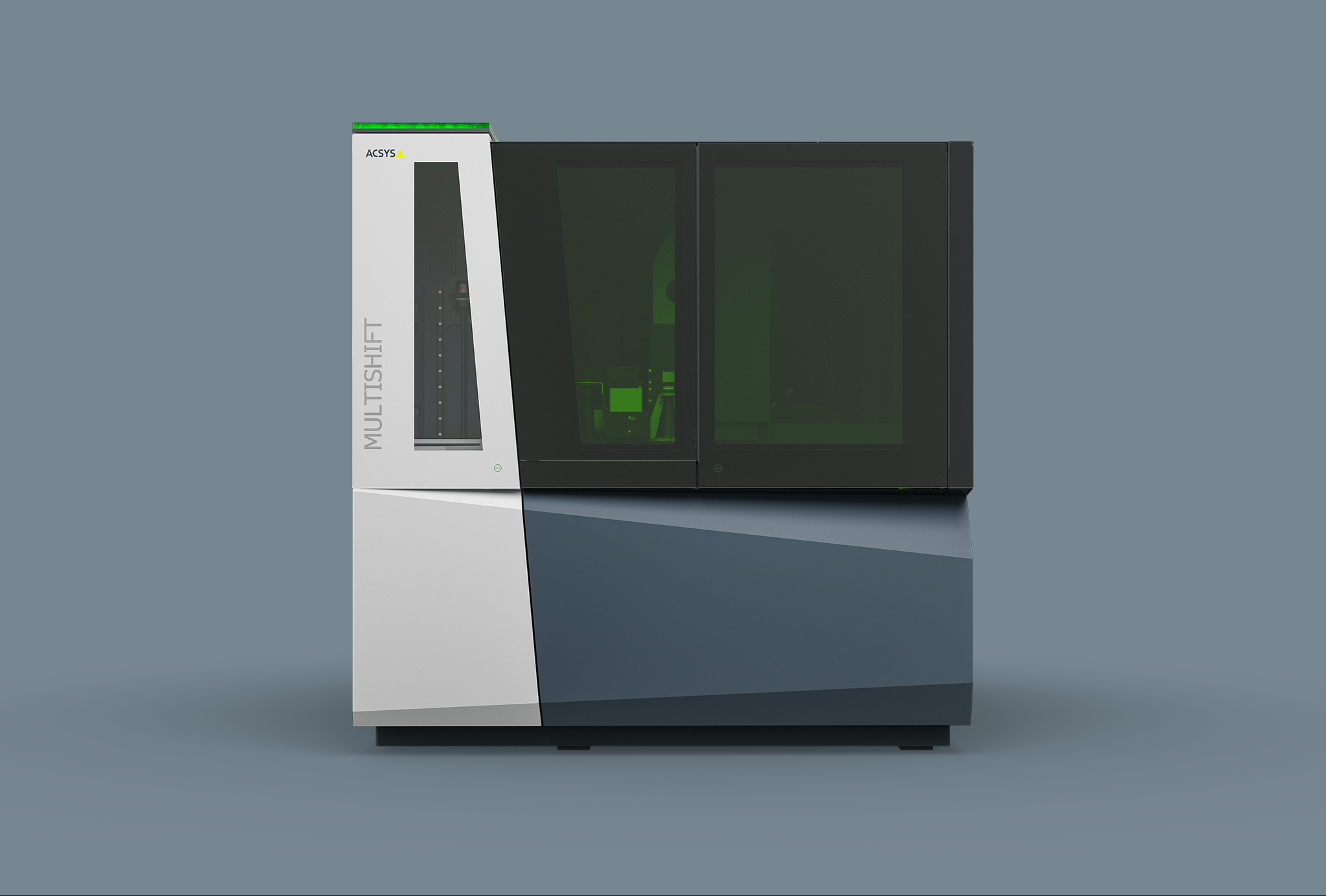

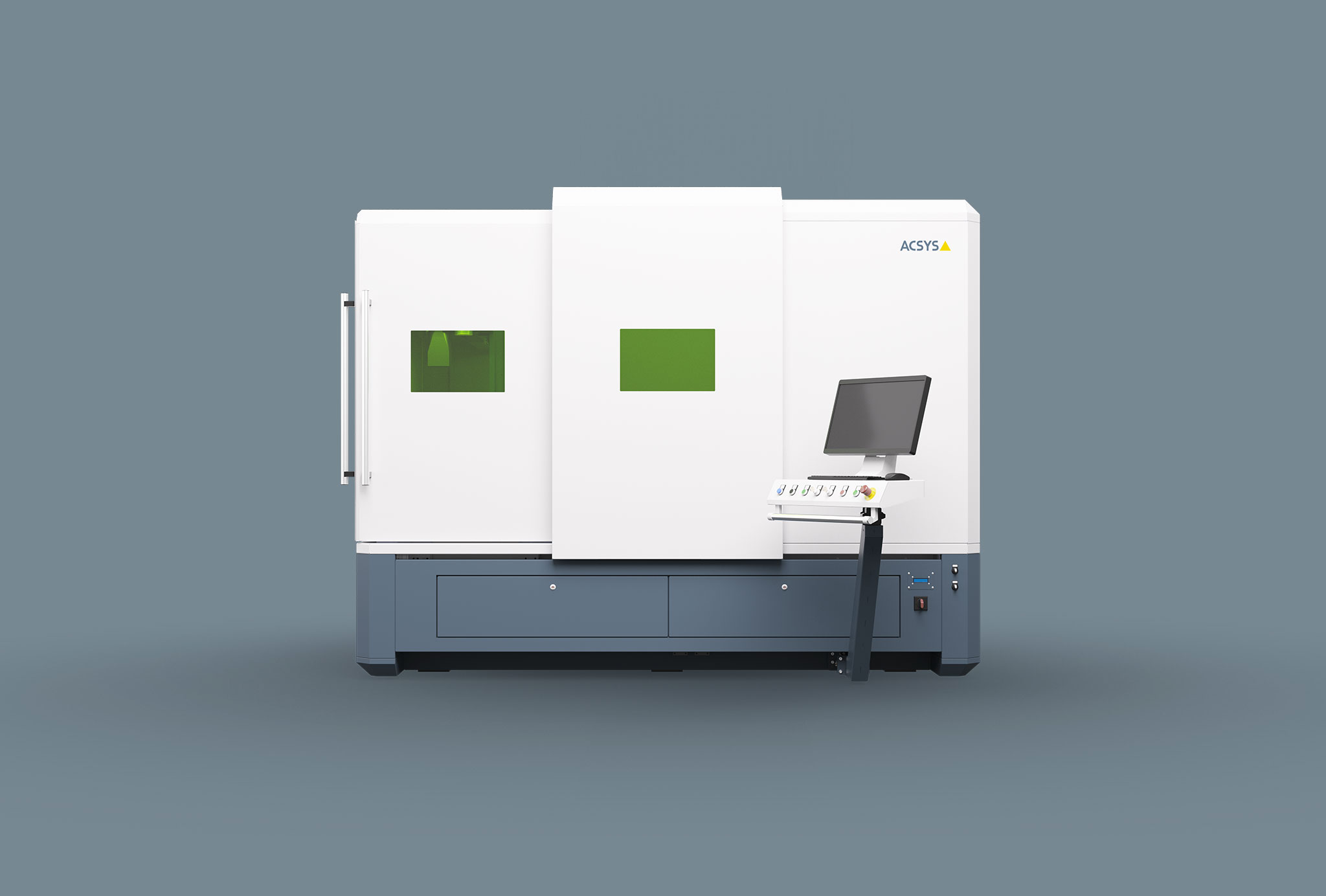

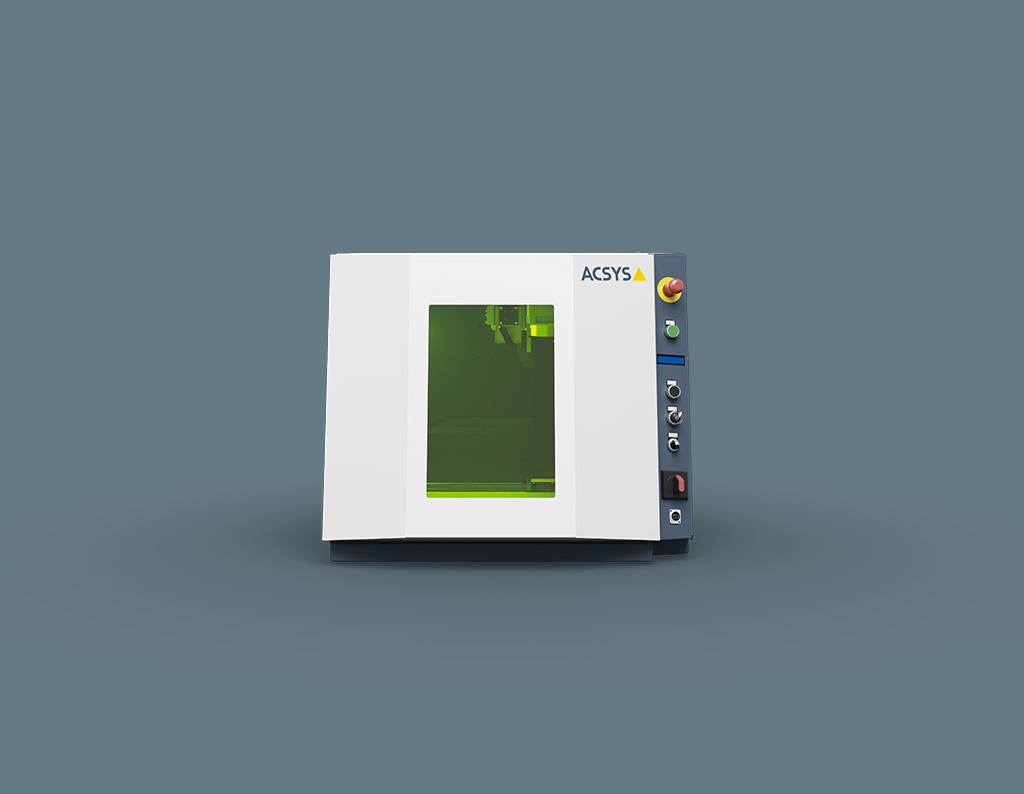

Products and solutions

Do you have any questions?

Our application consulting service supports you with all questions relating to your application.