Marking

Efficient and permanent labeling of a wide variety of materials and workpieces.

The laser marking process is used for labeling or marking workpieces. Advantage: Almost all materials can be marked by laser. The laser markings are waterproof, smudge-proof and durable. They can be applied quickly, individually and automatically. This is what makes the process so efficient and the method of choice for permanent part marking.

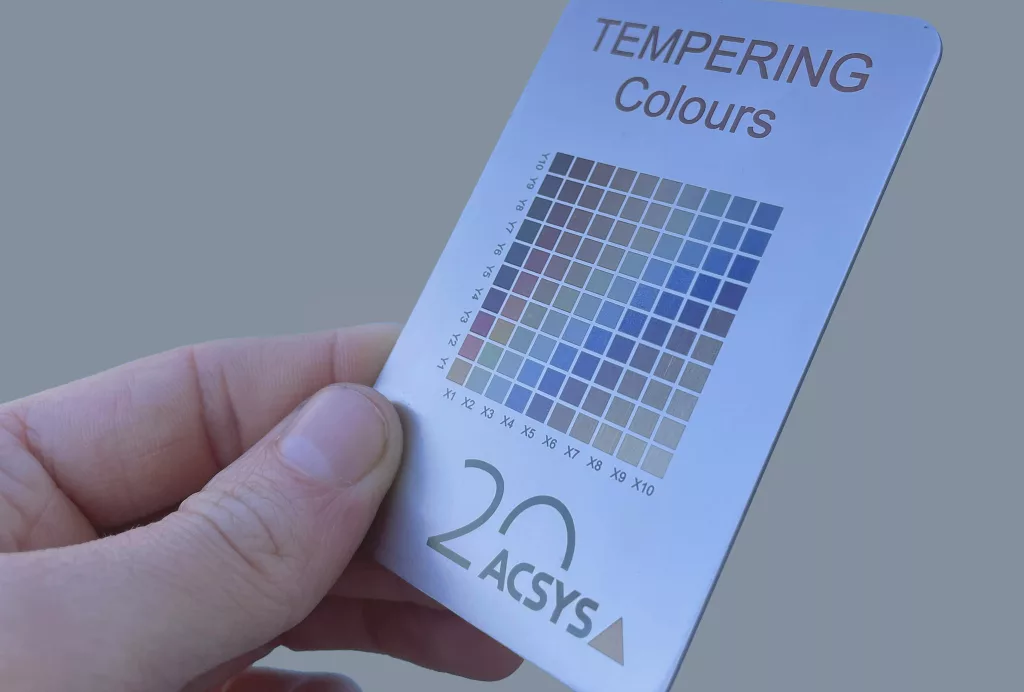

Tempering mark

When metal is heated, it becomes discolored. It takes on a different color depending on the temperature and duration of heating. This phenomenon is known as the tempering effect. Example of unalloyed tool steel: This turns white-yellow at a tempering temperature of 200 °C, turns purple-red at 270 °C and gray at 660 °C. There are other shades in between. The laser allows tempering temperatures to be achieved quickly and precisely and metal surfaces and structures to be produced in different colors without the use of additives. The markings are temperature-stable up to the lowest tempering temperature used and can be realized with maximum accuracy. Laser systems from ACSYS position the colors with micrometer precision.

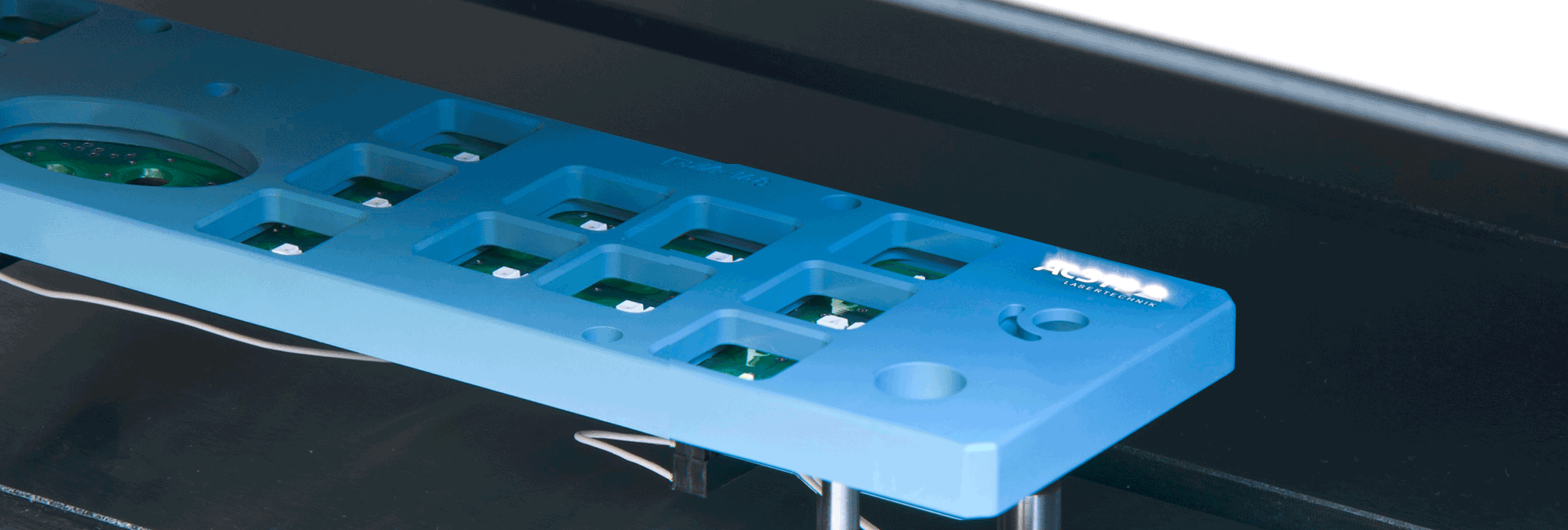

Deep lettering / engraving marking

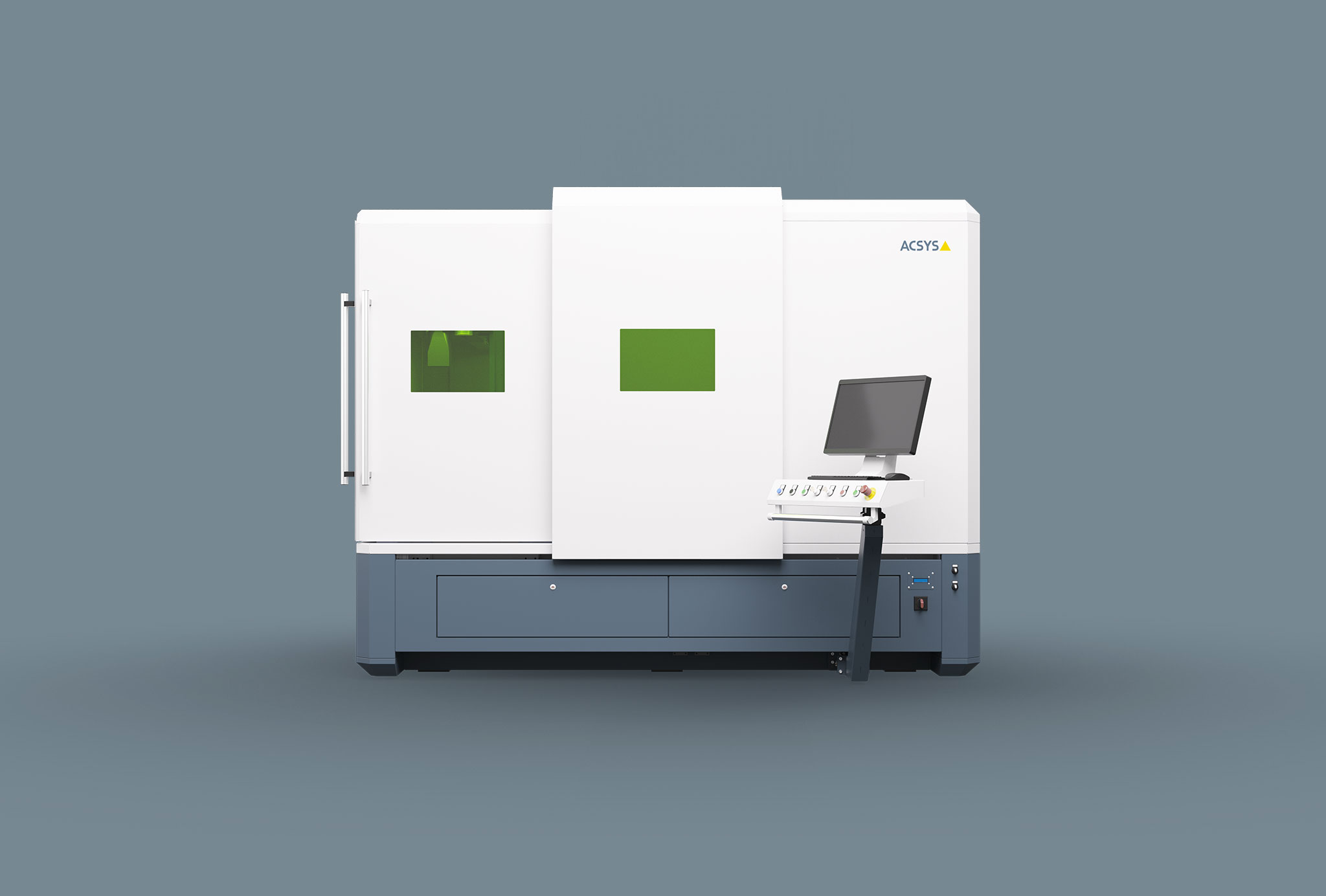

Deep marking is based on the same process principle as laser engraving: material is selectively melted and vaporized using the thermal energy of the laser beam. This laser-induced removal by melt displacement results in a slightly deeper marking on the machined workpieces. Laser systems from ACSYS can even handle the process fully automatically, meaning that blanks can be marked in non-productive times and without operating personnel, and even large-scale deep marking on flat or round parts is possible.

Foaming

This process is particularly suitable for marking technically suitable plastics. How it works: The laser beam melts the surface of the plastic. Gas bubbles form in the material and are trapped when it cools. This increases the volume of the plastic in the processed areas, which now appear slightly raised. One of the strengths of ACSYS laser systems: thanks to their multi-axis functionality, they can even mark large plastic webs in one piece.

Carbonize

During carbonization, the laser radiation penetrates the material and is absorbed by colour pigments. These react chemically, resulting in a permanent color change in the material itself. The surface of the workpiece remains virtually unchanged. Important to know: The effect described can only be achieved with plastic materials, some paints and technical ceramics. It depends largely on the wavelength of the laser radiation. The color changes can be controlled by selecting the pigments and the base material.

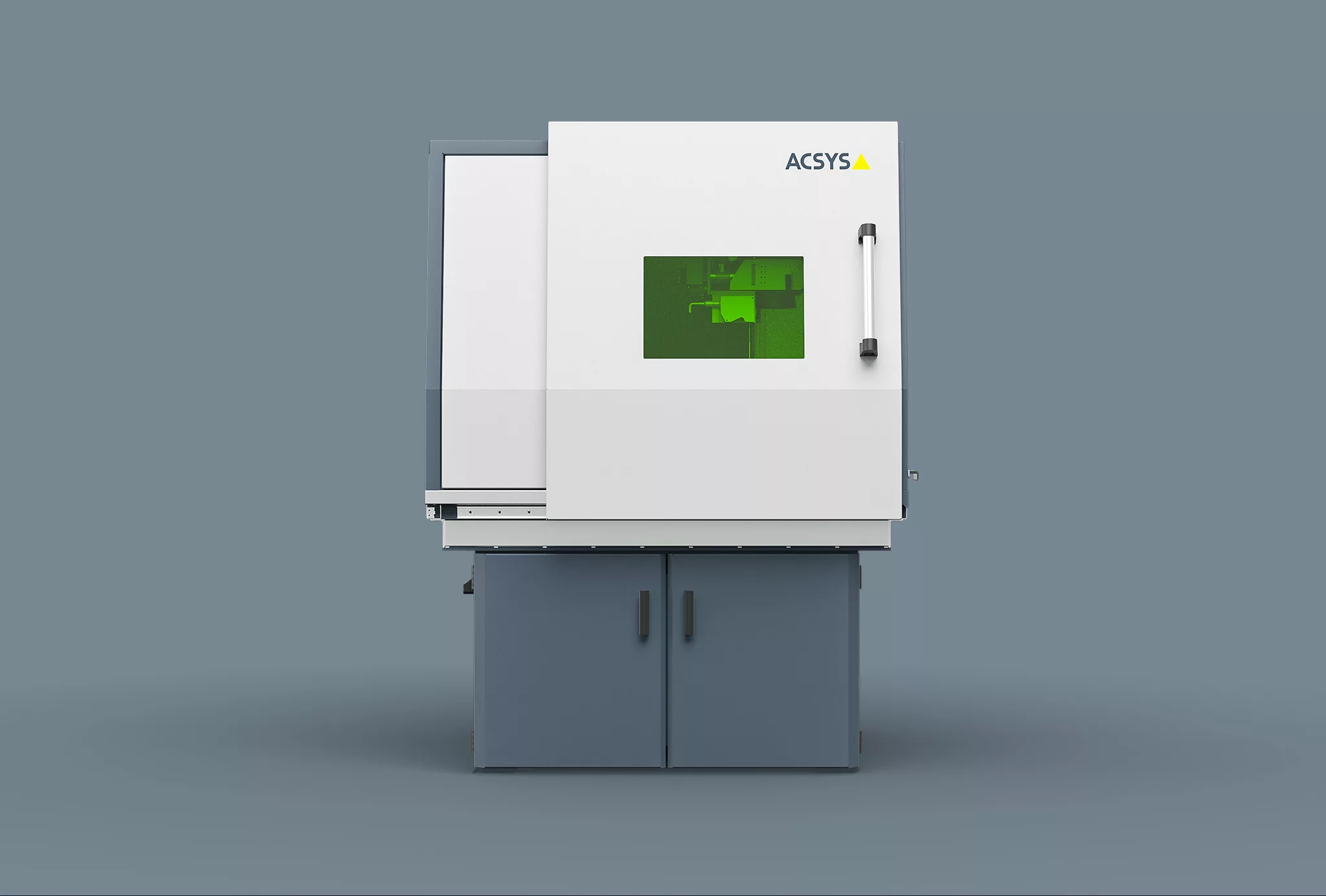

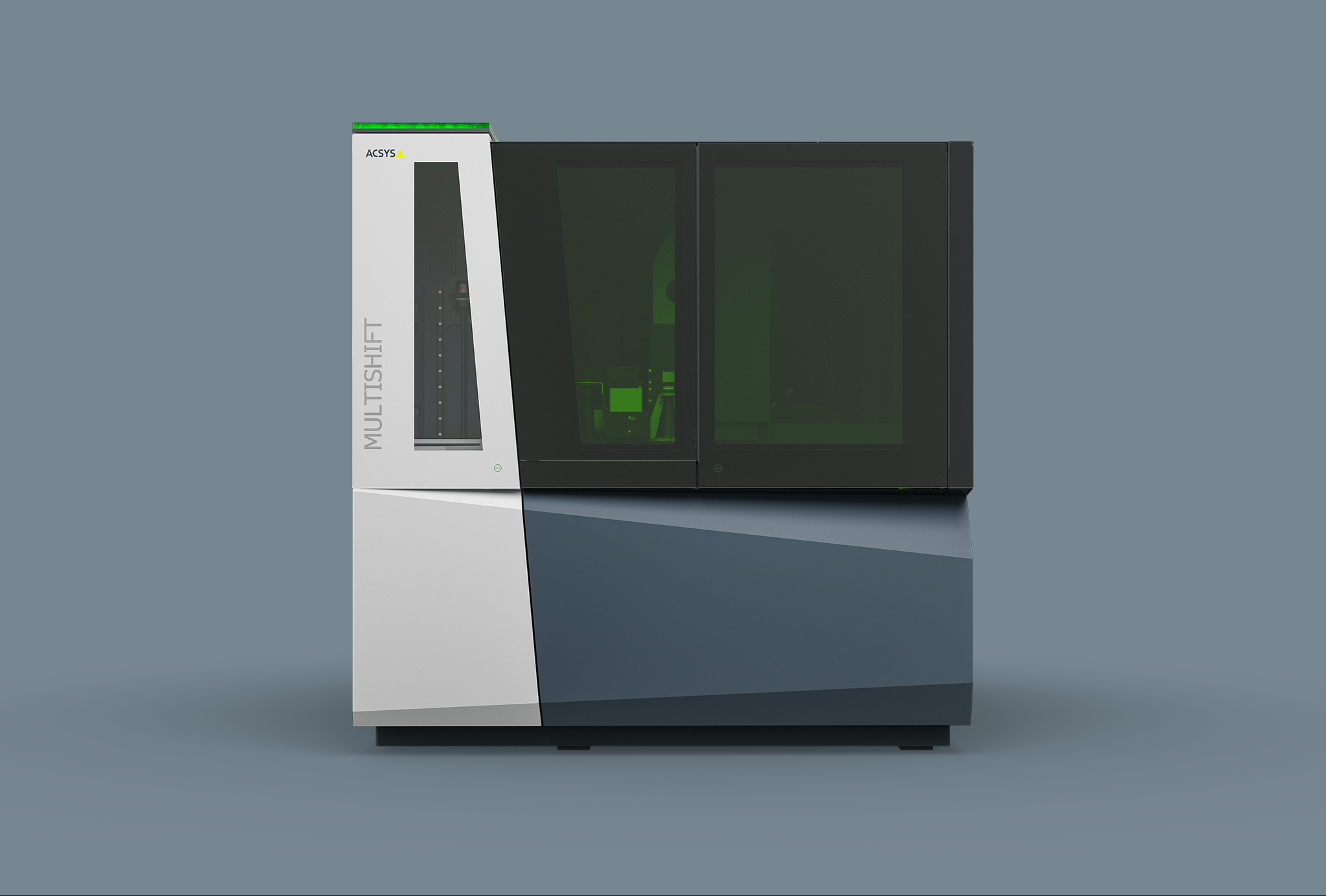

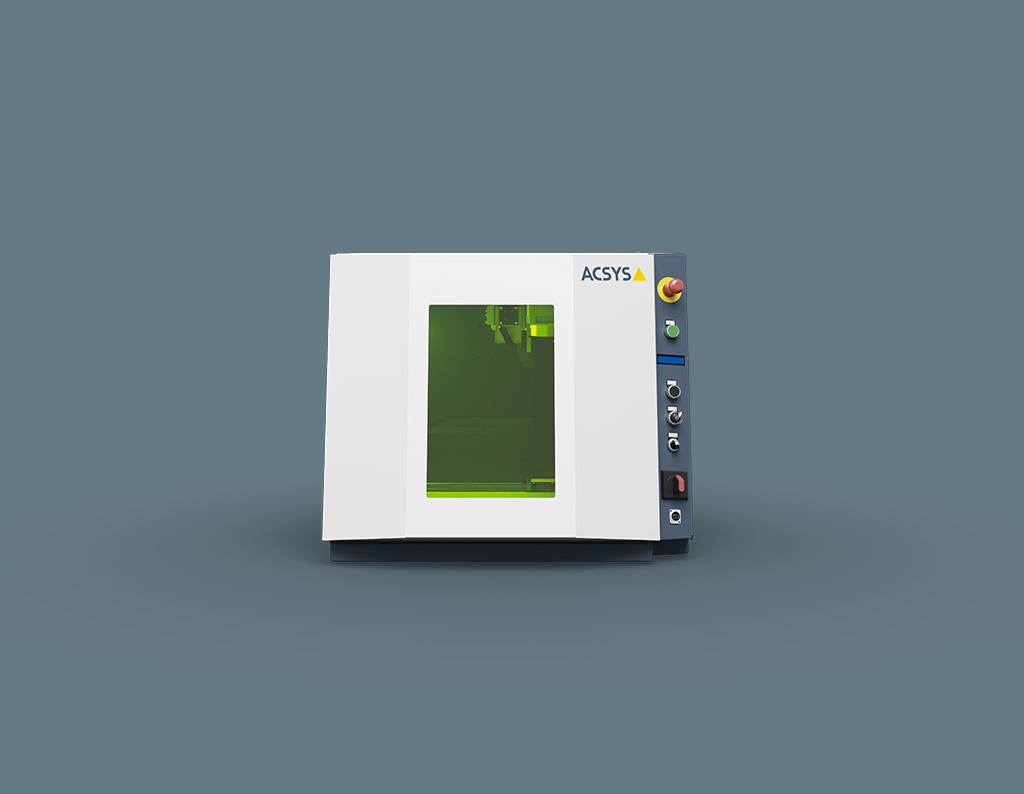

Products and solutions

Service, support and customer service

You can rely on that.