Medical technology

Laser systems from ACSYS ensure maximum precision, flexibility and sterility for medical products. Even the smallest components can be efficiently and precisely marked, engraved, structured, cut and welded using laser technology. Manufacturers of MedTech products have been using our customized laser systems for the production of surgical instruments, implants and medical devices for many years. We are the first port of call when it comes to laser processing in medical technology. With our many years of expertise in medical technology, we are the first port of call when it comes to top quality, maximum process reliability and compliance with medical and hygiene standards in the manufacture of medical products and solutions.

Permanent marking

With the help of laser marking, important information can be permanently applied to implants, medical equipment and MedTech devices. Especially when it comes to cleaning and sterilization, marking with laser technology offers an advantage over conventional methods. In addition, individualization via barcodes, logos or serial numbers can be easily integrated into the software. Even complex 3D geometries can be marked to a high standard using laser marking.

Fine blanking

Laser fineblanking is particularly suitable for medical products that are based on tubular blanks. It can be used to cut a wide range of extremely fine components out of metal, plastic or organic material without contact, from stents to aortic valve replacement (TAVI). In addition, Ultra Short Pulse Lasers (USPL) offer an efficient and precise solution for fine cutting of temperature-sensitive materials such as Nitinol.

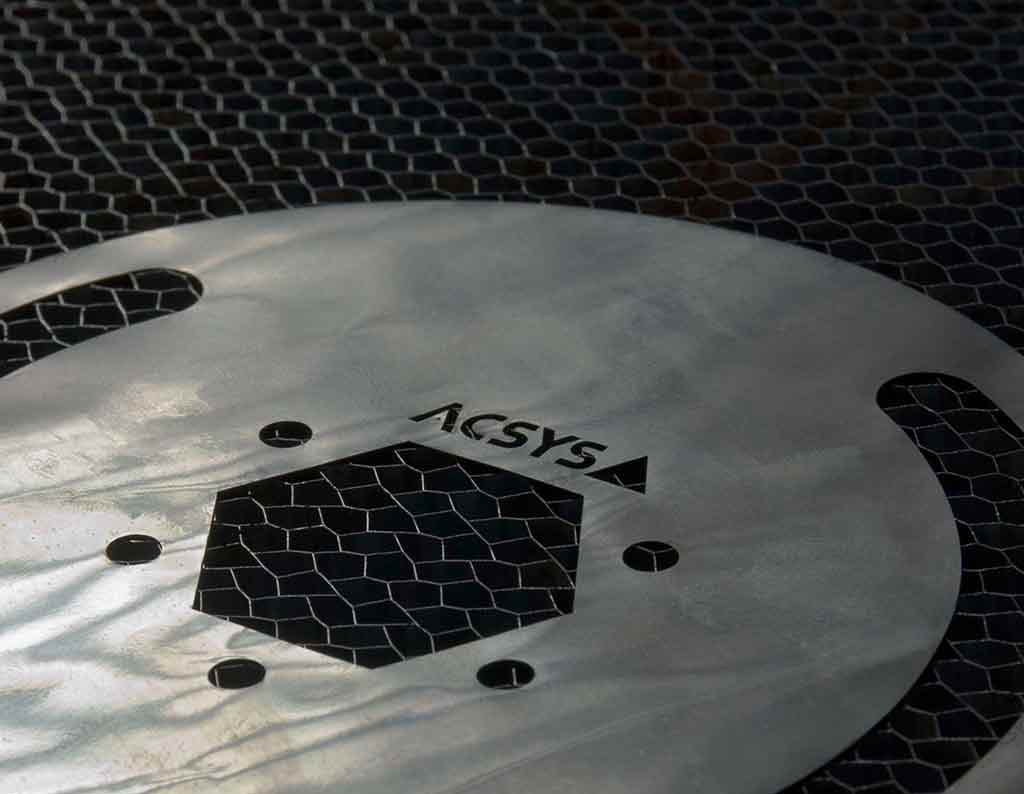

Micromachining

The possible applications for laser microstructuring in medical technology range from osseointegration and microfluidics to the lotus effect. Femtosecond lasers can be used to create micro- and nanoscale structures on almost any surface and geometry. Compared to conventional processes such as etching technology, processing with ultra-short pulse lasers (USPL) offers significant advantages in terms of quality, efficiency and environmental friendliness. Femtosecond lasers can also be used to clean surfaces, for example to remove impurities from upstream processes.

Products and solutions

Your ACSYS laser expert

Do you have any questions?

I am happy to help.

Ardalan Masoumi

Business Development Manager

Telephone: +49 7154 80875 531

E-Mail: a.masoumi@acsys.de