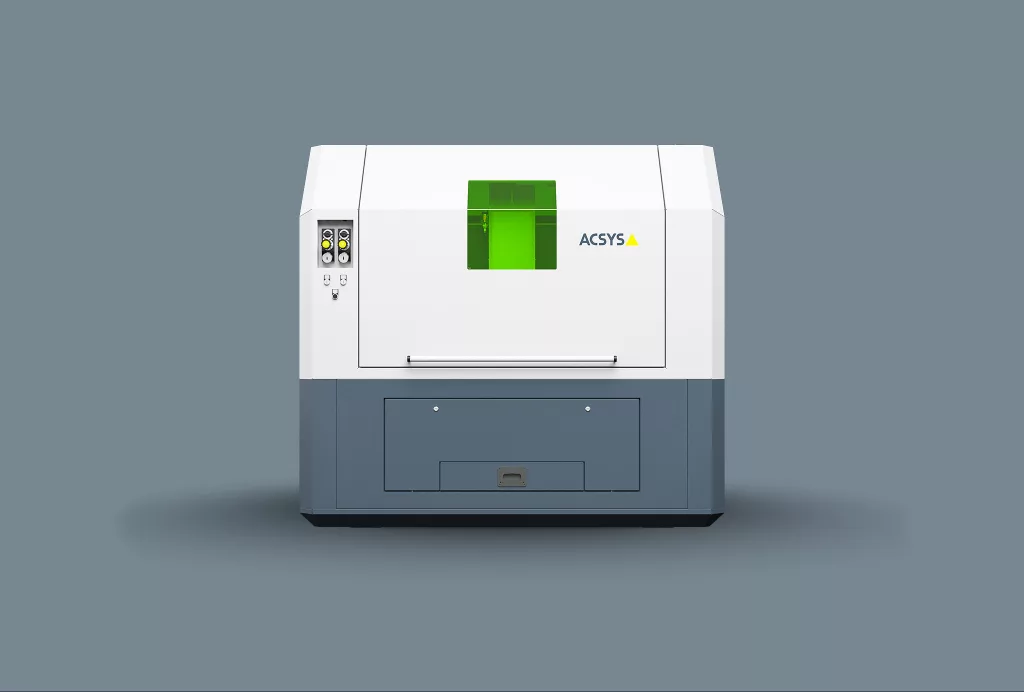

Machine & tool construction

Laser processing systems from ACSYS perform important tasks in machine and tool construction. The spectrum ranges from laser integration in machines and systems, through versatile laser applications for the manufacture of tools, to the cleaning, repair and functionalization of materials. Leading manufacturers in machine and tool construction rely on the unique combination of laser technology, software and process know-how from ACSYS for efficient and precise laser marking, laser engraving, laser structuring, laser cutting and laser welding.

Automation

Process automation is playing an increasingly important role, especially in machine and tool construction. That is why we offer laser processing solutions tailored to your needs and individual challenges from a single source. Anyone can promise you this, but we have proven it in practice in numerous projects – it is not for nothing that market and quality-leading companies have been relying on ACSYS solutions for more than 20 years. The spectrum ranges from mechanical automation, such as rotary tables, conveyor belts or film handling with rollers for winding and unwinding, to optical solutions and special solutions, such as wafer handling or the separation of bulk goods, through to software solutions with automatic pallet recognition via RFID and corresponding parameterization of the system.

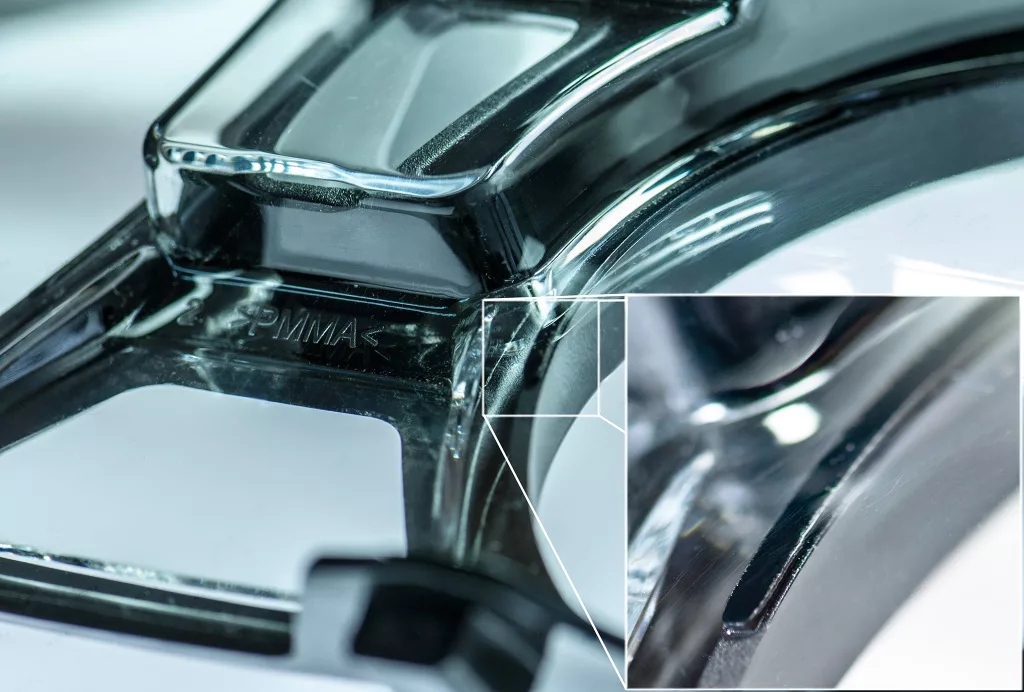

Spot and seam welding

Metals and plastics can be joined particularly finely, precisely and permanently with ACSYS laser systems. Laser welding is carried out without the addition of material, which means that the processed materials retain their original properties. And with the flexible power and pulse design, special effects as well as special pulse shapes and trains can also be created. Whether the smallest spots or meter-long weld seams: ACSYS laser welding systems deliver the highest quality and repeat accuracy for tool, machine and mold making.

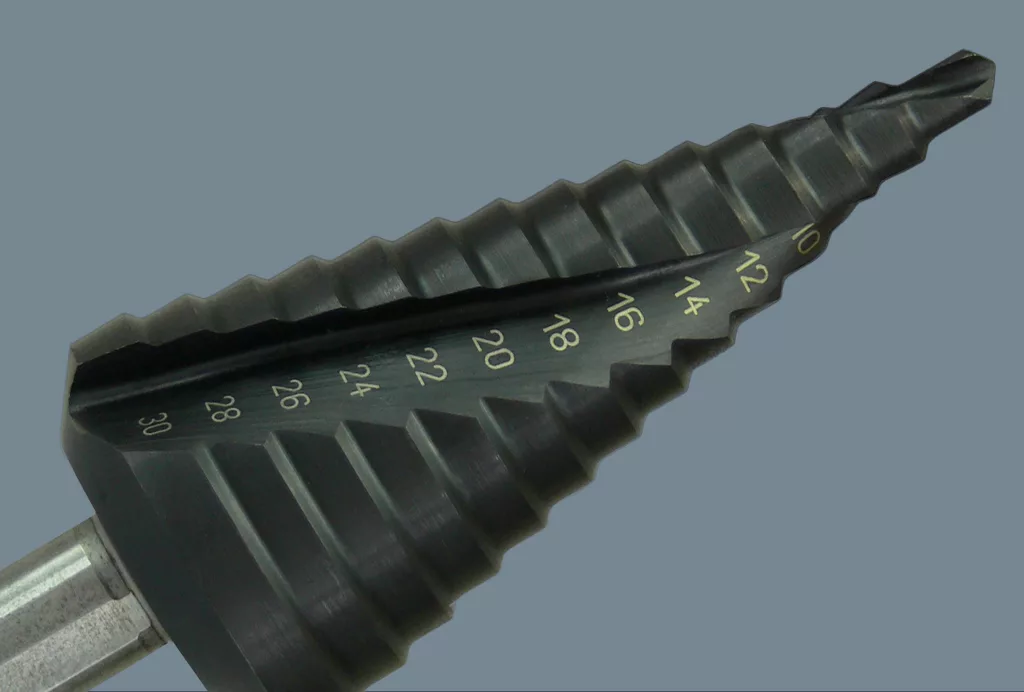

Permanent markings

Laser marking ensures that important information is permanently applied to tools, molds and machines. Particularly in tool and mold making, where rough conditions prevail due to corrosion, abrasion or dirt, marking with laser technology offers significant advantages over conventional methods. In addition, ACSYS laser systems offer the option to feed barcodes, serial numbers and logos into the software. Benefit from a wide range of different laser systems, automation and processes to achieve high-quality, permanent markings and engravings – even in series production with high throughput.

Laser cutting

Laser technology can be used to cut metals and plastics – or more precisely, to thermally separate them. ACSYS laser systems really come into their own when it comes to the precise cutting of flat materials with high edge quality. Our laser systems are also capable of high-precision and fast interpolated laser cutting. There are generally three laser cutting processes. These differ in the additional gas that is introduced into the parting line axially to the focused laser beam. And fine cutting with Ultra Short Pulse Laser (USPL) takes precision, edge radius and quality to a whole new level.

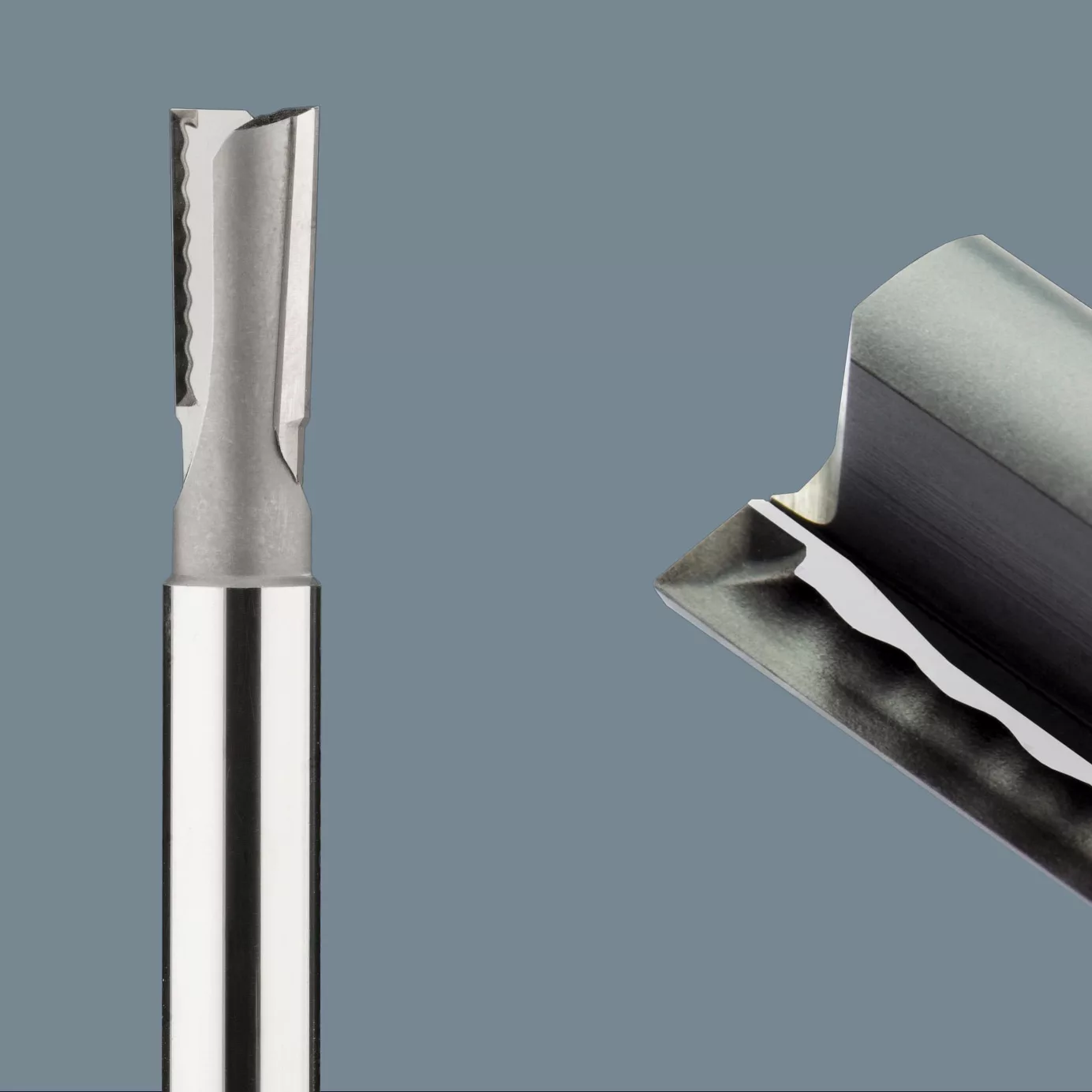

Miro engraving & surface functionalization

Self-cleaning, antibacterial or non-icing surfaces are just a few examples of laser-based surface functionalization. The latest findings from bionics are used, for example, via Direct Laser Interference Patterning (DLIP) to improve the adhesion of coatings, increase the corrosion resistance of materials or minimize friction. ACSYS Ultra Short Pulse Lasers (USPL) help you to increase the service life of tools, improve precision and efficiency in production and establish sustainable alternatives to conventional processes.

Products and solutions

Your ACSYS laser expert

Do you have any questions?

I am happy to help.

Manfred Kaiser

Sales

Telephone: +49 162 2999 026

E-Mail: m.kaiser@acsys.de