Welding

Fine and precise spot and seam welding of metals and plastics.

Fine, precise and permanently joined: ACSYS laser processing systems stand for welding processes of the highest quality. Different processes are used depending on the material, but ACSYS welding systems always work particularly efficiently without adding material. What’s more, thanks to the option of flexible power and pulse design, it is even possible to create special effects as well as special pulse shapes and trains.

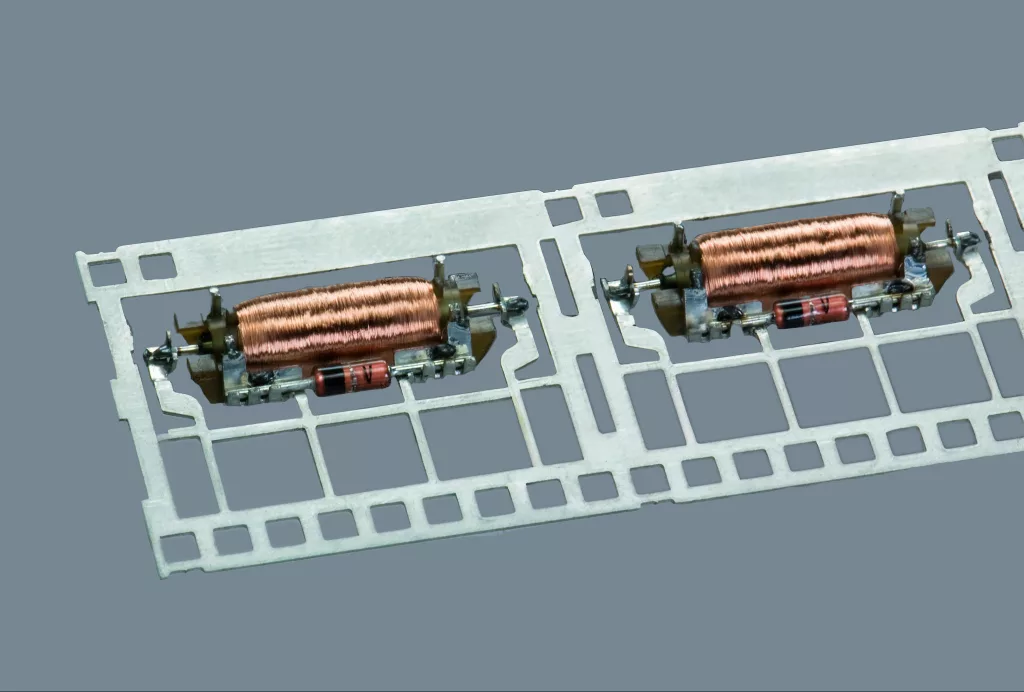

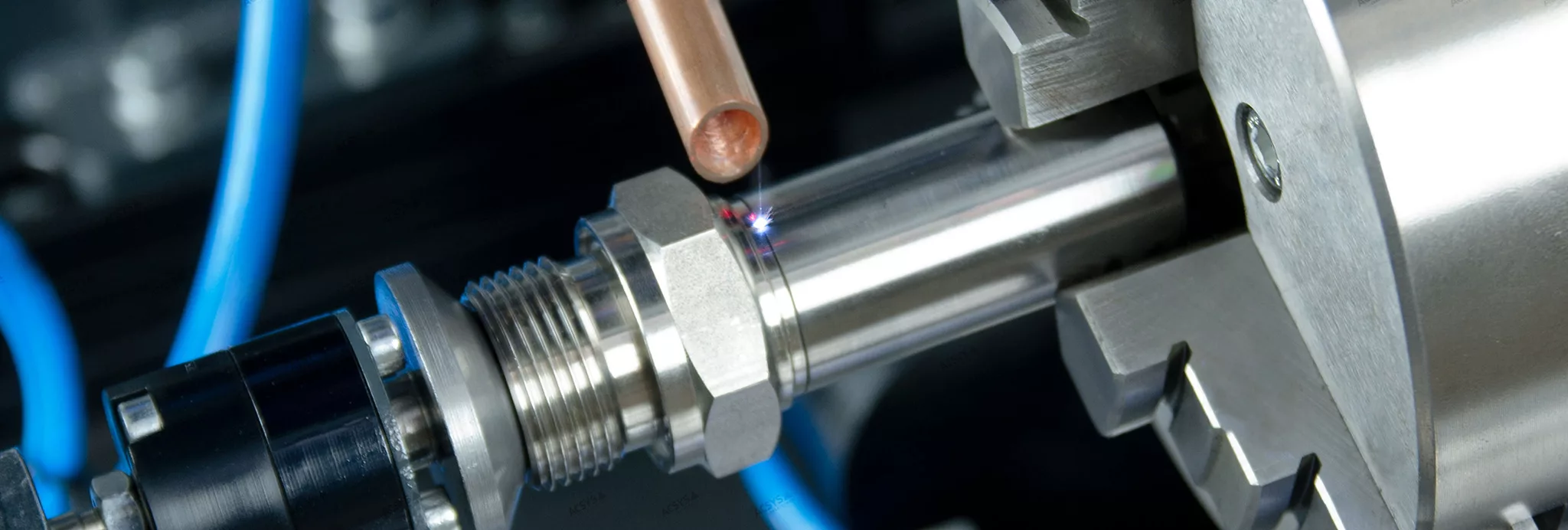

Metal welding

If metal components are to be joined together inseparably without the addition of material, there is no alternative to laser welding. It also offers enormous flexibility. With the innovative fiber laser technology from ACSYS, the spectrum ranges from the finest spot welds to meter-long deep-welded seams with slim geometries and minimal distortion. Thanks to the very effective focal depth of our lasers, process-tolerant welding is possible even with materials with different wall thicknesses or when the alignment is not perfectly perpendicular.

Good to know: ACSYS laser processing systems are capable of both metal welding processes: heat conduction welding (Melt Welding / Fusion Welding) and deep penetration welding (Keyhole Welding).

Heat conduction welding

In heat conduction welding, the laser only melts the materials on the surface. The materials flow into each other, the melt solidifies. The result is a lasting connection. The process achieves welding depths of typically < 1 mm and is suitable for joining thin-walled parts. The laser produces a smooth, rounded weld seam that requires no post-processing.

Deep welding

During deep penetration welding, the laser beam creates a vapor capillary in the material, also known as a keyhole. This reaches approx. 1.5 times the diameter of the laser beam focus and is drawn through the workpiece using the system’s movement system. The molten metal flows around the capillary and solidifies on its back. The result is a deep, narrow weld seam with a uniform structure.

This process is used to join several layers of material at once and to achieve high welding depths. It is characterized by a high degree of efficiency and high welding speeds. The very small heat-affected zone protects the material and prevents warping.

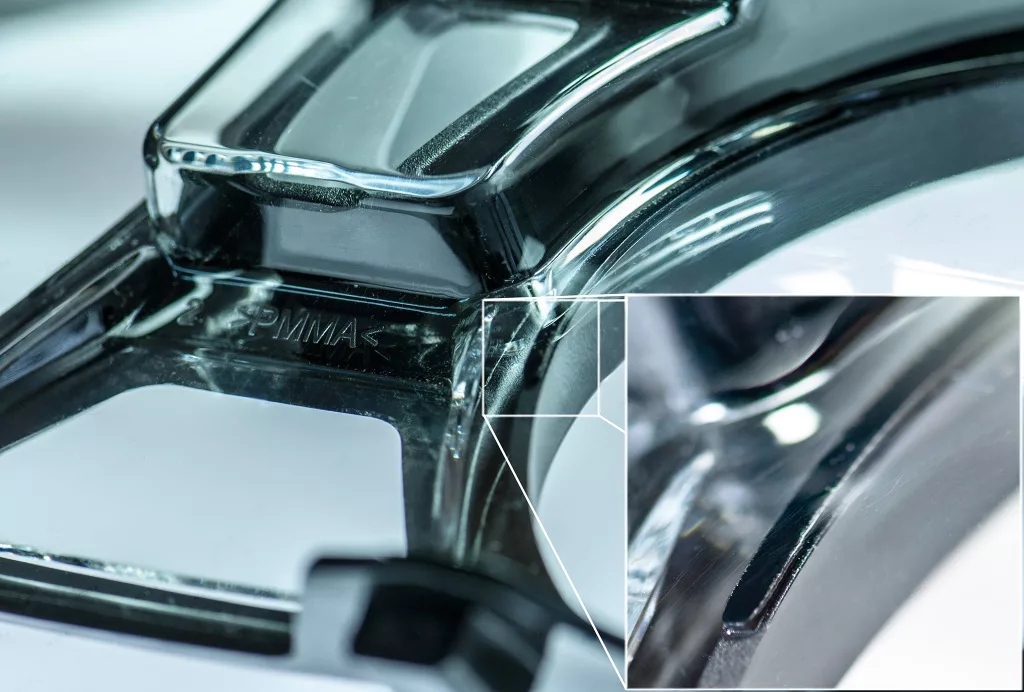

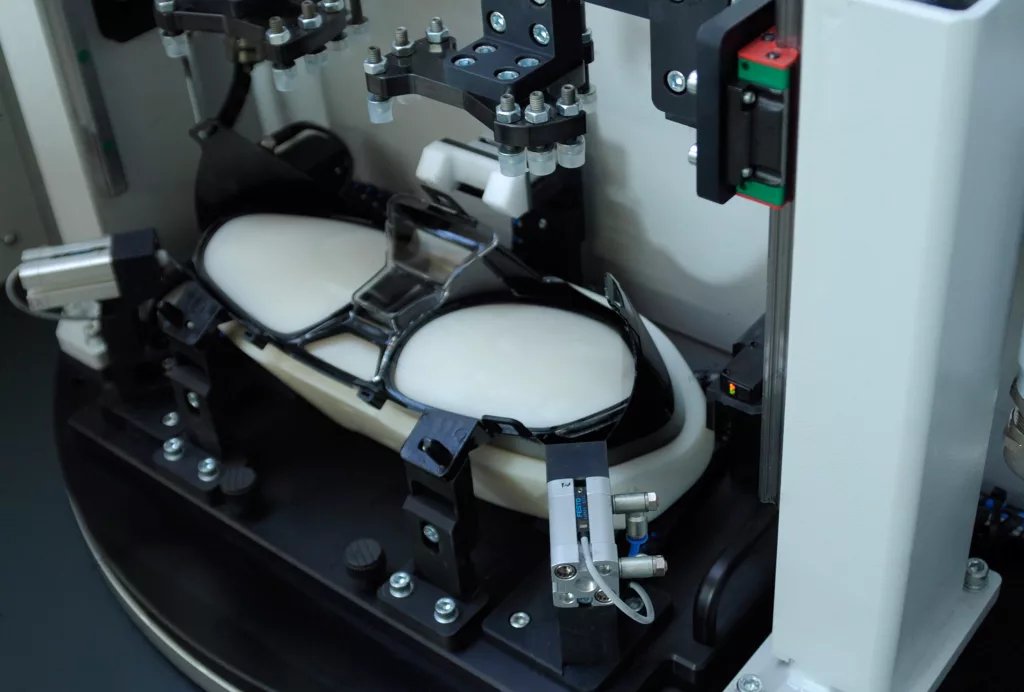

Plastic welding

Laser welding of plastics is carried out using the overlap welding process. It works on the principle of laser absorption welding. The process: The two joining partners are overlapped on top of each other. The laser beam penetrates the upper joining partner and the energy is absorbed by the lower joining partner. This heats up. It transfers the heat to the upper joining partner so that a common fusion band is formed. While this cools, pressure is applied from the outside to create a high-quality welded joint.

Important: The same or compatible plastic materials and a component-specific optimized laser technology must be selected for welding. We will be happy to advise you.

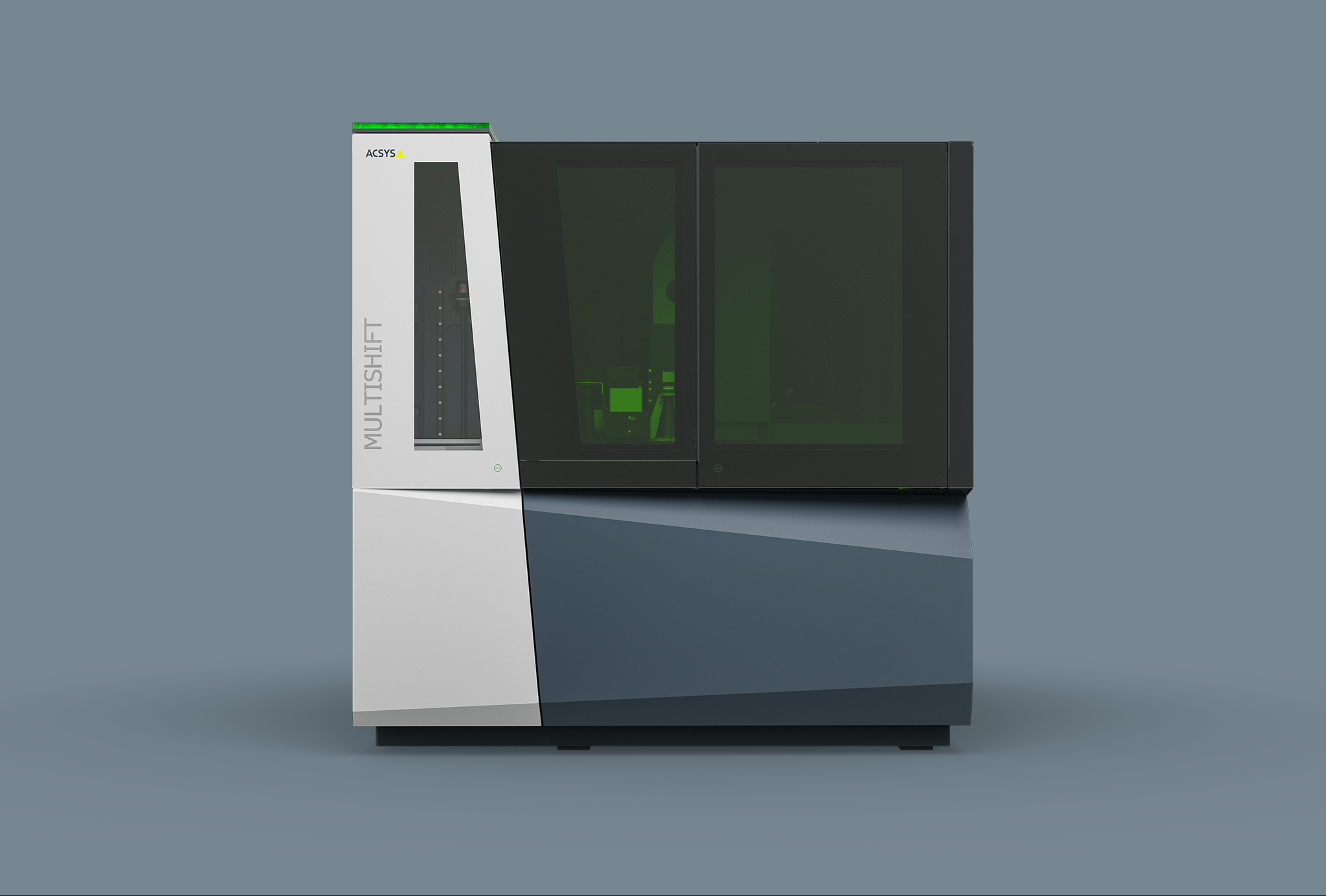

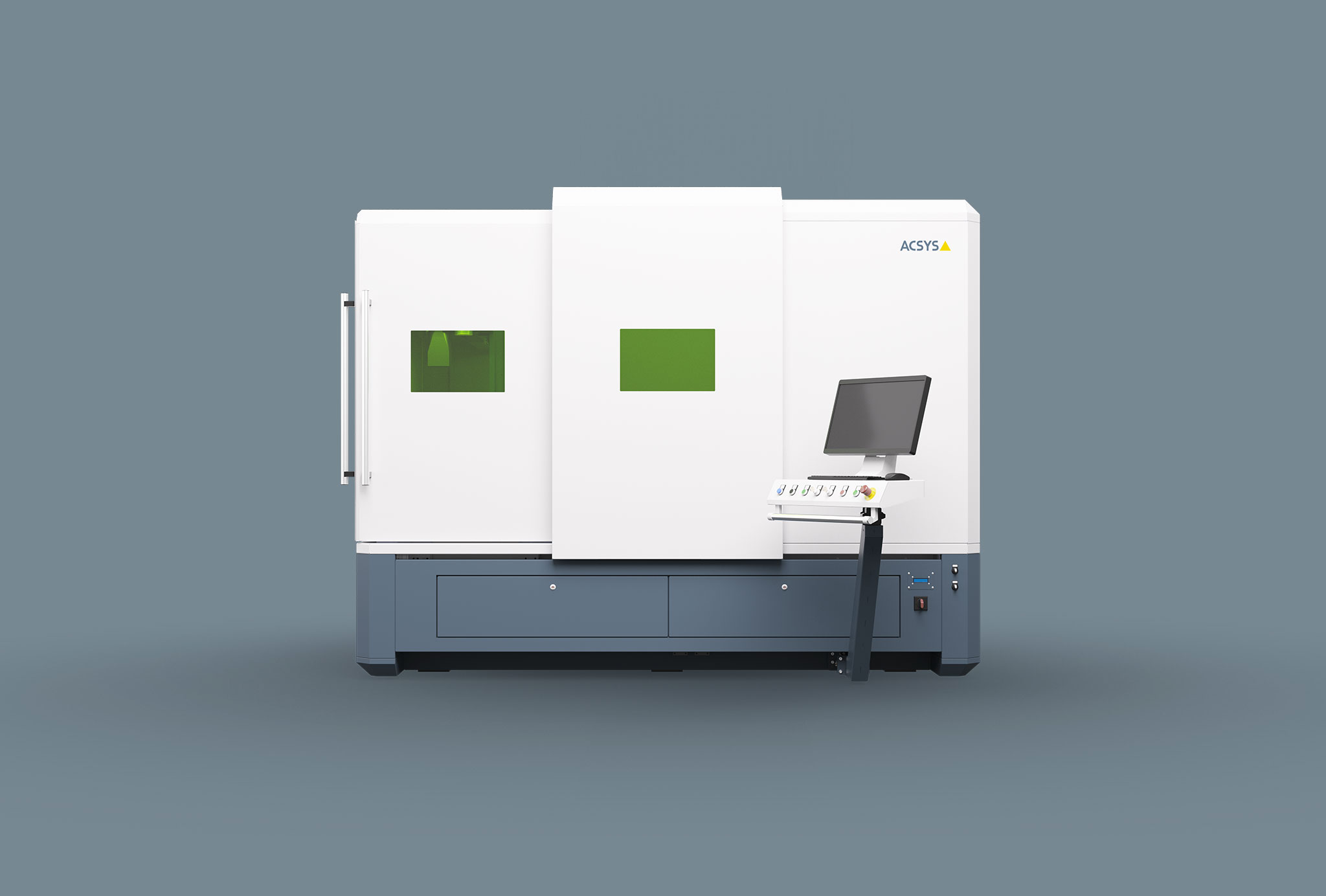

Products and solutions

Would you like a little more?

Customer-specific adaptations are almost always possible with laser systems from ACSYS.