Fully automatic labeling of terminal strips

There is more to the whole than the sum of its parts. A good example of this is the Klippon® Automated RailLaser from Weidmüller. The joint development of the global player in electrical connection technology and ACSYS enables quick and easy labeling of assembled mounting rails for efficient control cabinet construction. In the following case study we will show you what role laser technology from ACSYS plays and how the system helps to save 90% of time compared to conventional processes.

Automation from A to Z

Holistic approach as a starting point

Weidmüller views control cabinet construction as a holistic process from planning to installation and operation. Especially in times of full order books and an increasing shortage of skilled workers, it is very important to make value creation processes more and more efficient. This also applies to switch cabinet construction, where new digitalization and automation approaches play a decisive role. In order to mark pre-assembled terminal strips more efficiently and to prevent errors when separating, assigning and rasterizing individual markers and to ensure excellent marking quality, a new type of solution for an automated rail laser was to be created.

Ready to robot

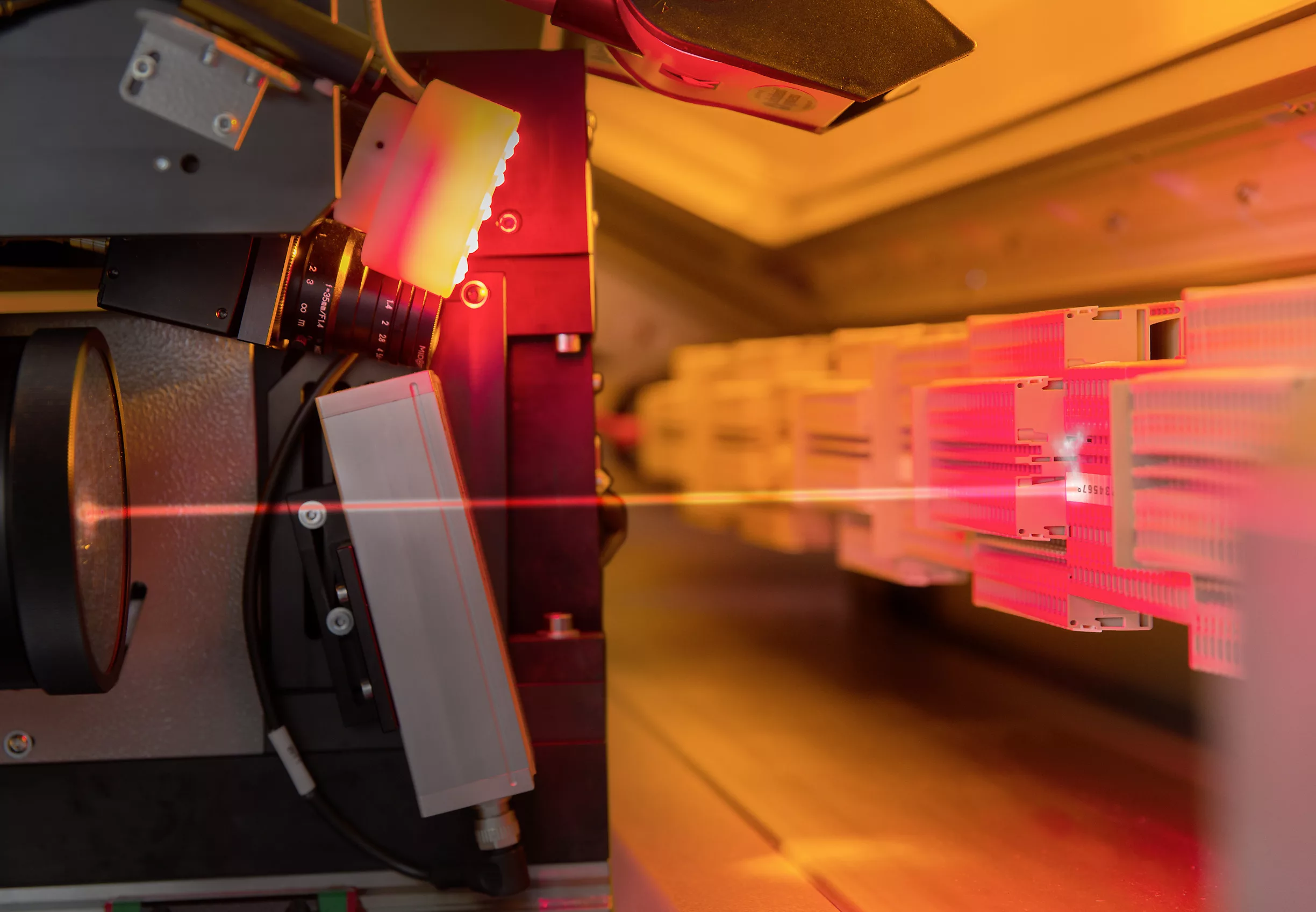

In order to further advance automatic terminal strip assembly, with the added value of a digitalized and automated process chain for machinery and production systems, a marking process was to be developed using laser technology in order to integrate fully automatic marking into the existing process chain. ACSYS contributed the corresponding know-how for high-quality laser technology as a technology and development partner. The result is the Klippon® Automated RailLaser, which has been distributed exclusively by Weidmüller since 2019.

Universal labeling options

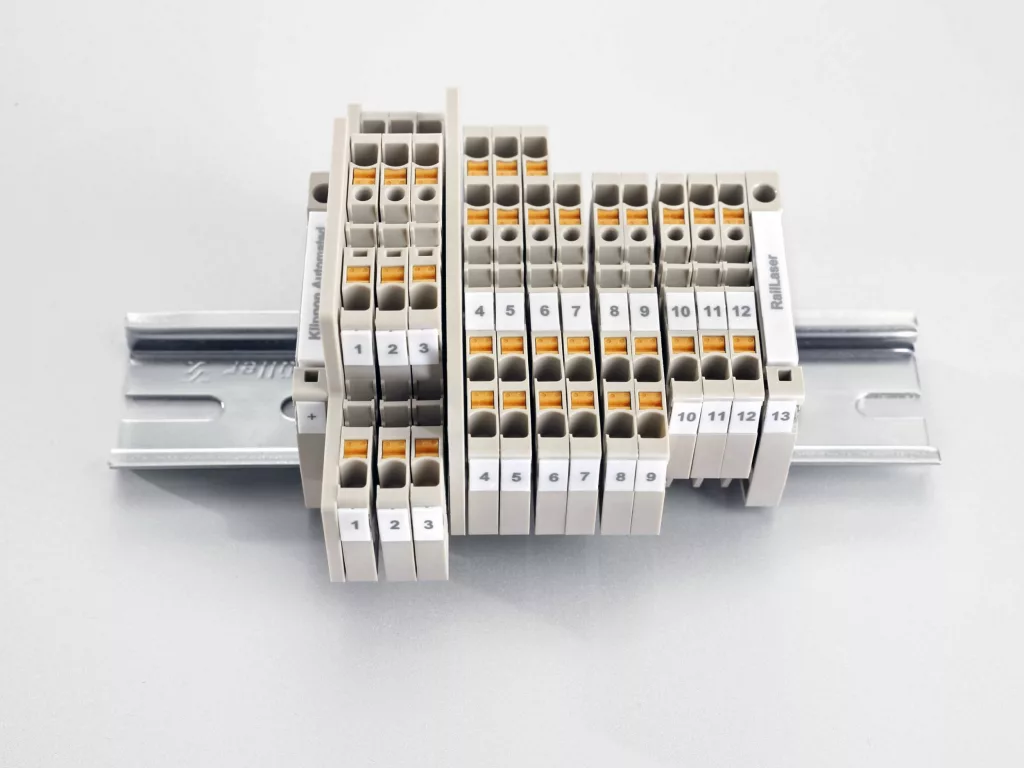

Thanks to the innovative laser technology, no special markers are required. In addition to the pre-installed white markers, all markers from the Weidmüller standard portfolio with a wide range of colors and materials can also be used. In combination with the Weidmüller Configurator (WMC) software, the laser system enables the fully automatic marking of pre-assembled terminal strips. The use of terminal blocks with pre-attached markings eliminates the need to separate, assign and mount individual markings. This enables time savings of up to 90% in marking processes. The laser marking of the terminal strips meets the highest standards of labeling quality.

Maximum flexibility

Thanks to the universal mounting rail holder and direct laser processing, it is possible to mark terminals, blocks and other mounting rail components very precisely, even with complex geometries. The mounting rails can be marked from 100 mm to 1,200 mm in length, with a height of between 7.5 mm and 15 mm and a total weight of up to 15 kg.

Conclusion

From recognizing the data matrix code on the back of the mounting rail, to setting the correct parameters for material and marking, as well as coordinating the hardware, software and necessary process steps, ACSYS Lasertechnik provided the necessary expertise and, together with Weidmüller, created a unique system concept for the Klippon® Automated RailLaser

Your ACSYS laser expert

Do you have any questions?

I am happy to help.

Manfred Kaiser

Sales

Telephone: +49 162 2999 026

E-Mail: m.kaiser@acsys.de