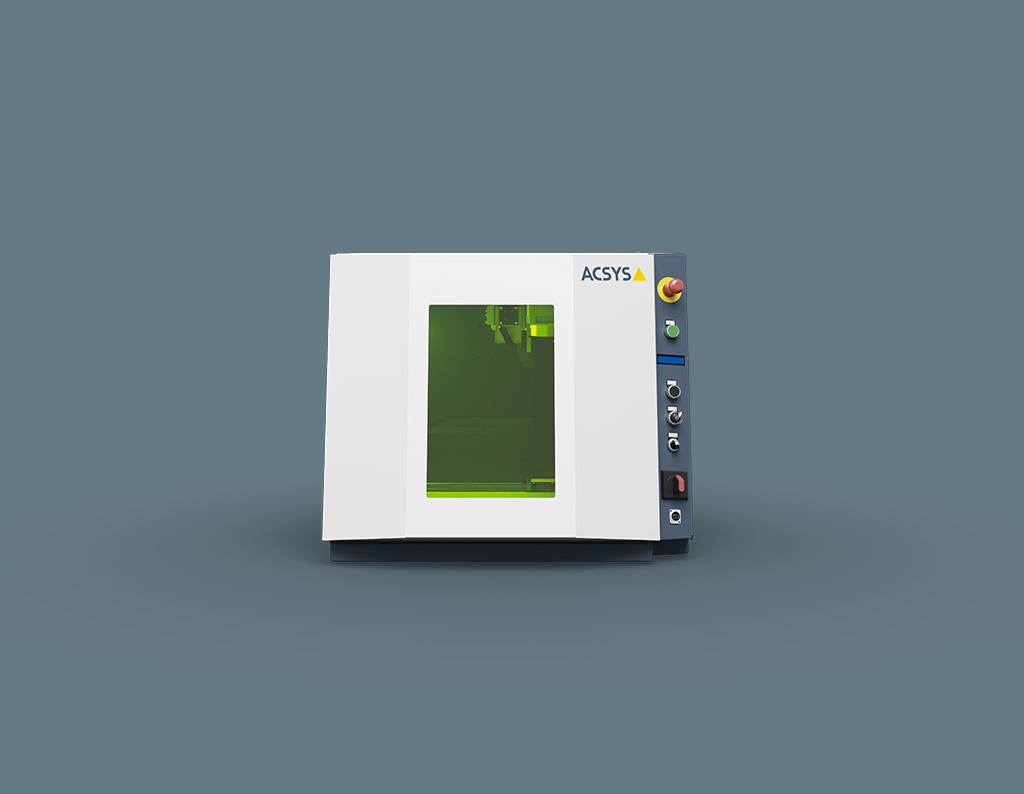

Lots of flexibility in the smallest of spaces

Do you need a versatile solution for processing individual parts and small batches? The OYSTER® is the compact answer with proven ACSYS precision. It adapts flexibly to a wide range of materials and requirements – and does so on a footprint that could hardly be smaller. It can also be upgraded with useful options, such as the innovative Live Adjust System (LAS) or customized software solutions from ACSYS.

The choice of professionals in a wide range of industries

Whether in jewelry manufacturing, medical technology, tool production or the advertising industry – OYSTER® has established itself as a reliable partner for precise marking and engraving. The optional X-axis, which significantly increases the machining area without compromising the compact external dimensions, further expands the range of applications.

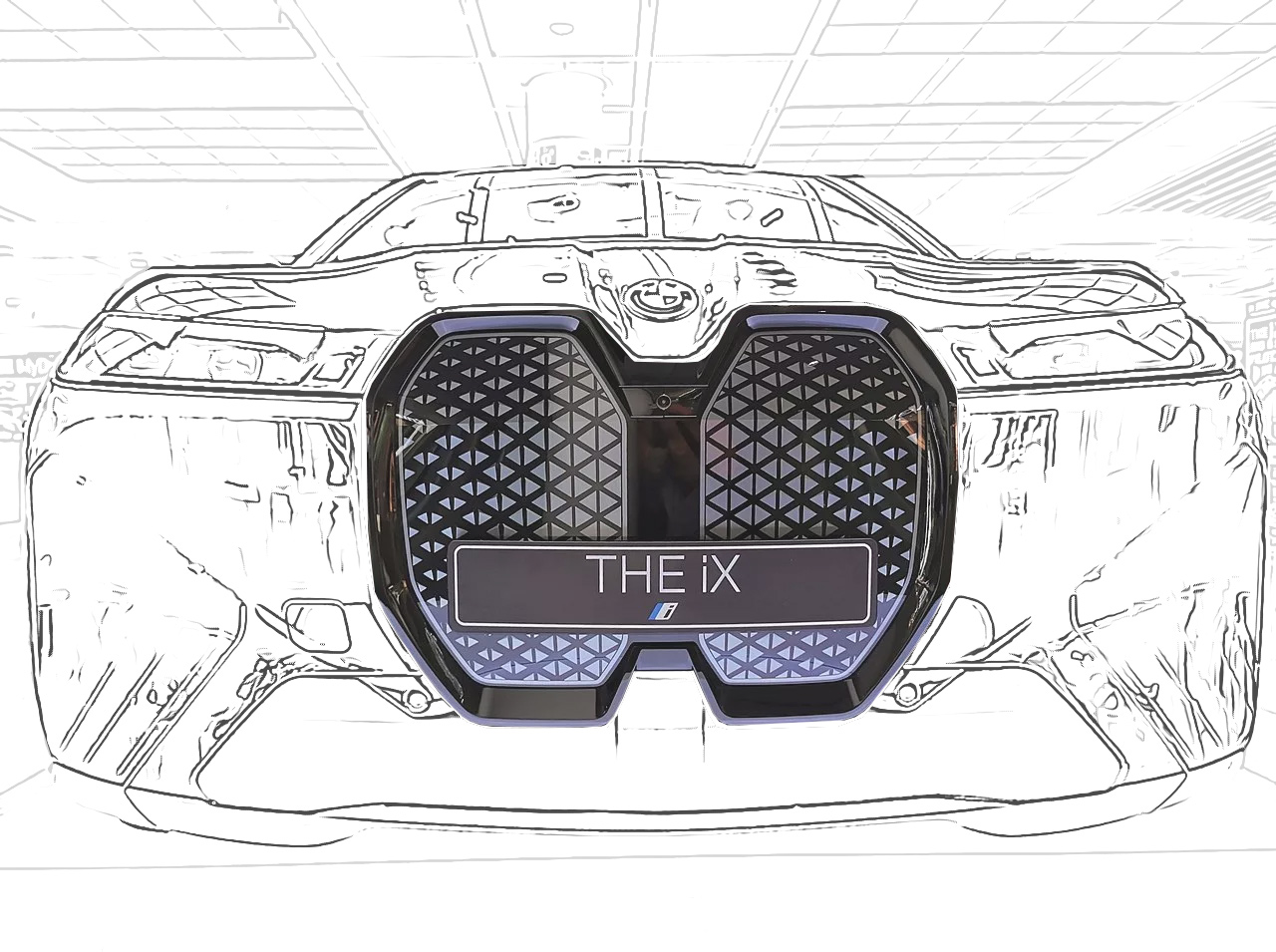

OYSTER®

Engraving, marking, structuring

The strength of the OYSTER® lies in its adaptability and precision. Whether it’s occasion marking, deep engraving or 3D engraving – it masters every challenge with flying colors. Their technological sophistication enables the processing of almost all materials, whereby the specific properties of the material determine the use and efficiency of the laser energy. Your entry into the world of laser precision.

The OYSTER® stands for:

- Versatile labeling and engraving techniques

- Fast and flexible processing of small parts

- High quality and precision

- Compact design for every workplace

- Expandability through optional X-axis

Discover precision and flexibility in compact dimensions: The OYSTER® from ACSYS.

Add-on technologies for specific requirements

Despite its compact dimensions, the OYSTER® delivers precision and efficiency in laser processing as standard. And with our unique portfolio of options, the OYSTER® can be customized to meet your individual challenges.

DFS – Double Focusing System

With the Double Focusing System (DFS), you can see at a glance whether the laser processing head is at the correct focus distance from the workpiece. The correct focus distance can be determined in this way, especially for surfaces that are difficult to access or difficult to measure.

A pilot laser marks the center of the laser processing field and also offers the advantage that either fitting rectangles or the contour lines of the layout can be displayed directly. A high-resolution camera transmits images directly from the interior to the monitor on the control panel. The Double Focusing System is also available with green laser systems.

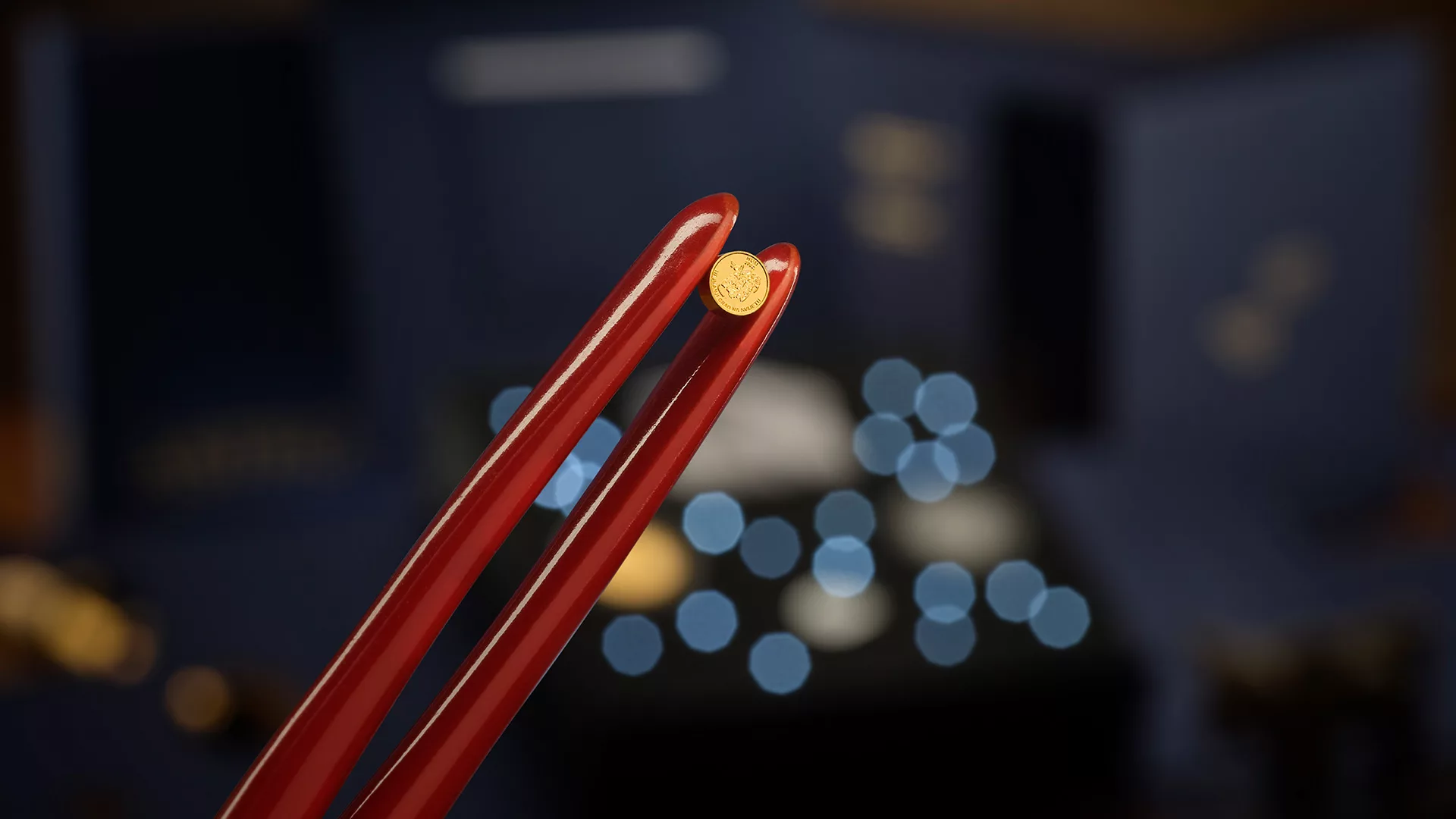

Dividing heads

ACSYS offers you various dividing heads for precise angular positioning and further turning of workpieces. Each of the devices is NC-controlled and has an electric rotary axis as well as a manually or electrically adjustable swivel axis. Dividing heads are used for the internal and external marking of rings and cylindrical or conical workpieces. They are available with manual feed or automatic feed with automatic loading.

LAS – Live Adjustment System

The camera-supported Live Adjustment System significantly reduces your set-up effort and enables the exact positioning of even the smallest workpieces in the system. The principle: a high-resolution camera transmits images directly from the interior to the monitor on the control panel. With the help of the infinitely variable digital zoom function, you can bring all the details of a workpiece onto the screen and place layouts with absolute precision. The target result is displayed as a preview. If required, new layouts, markings, barcodes or data matrix codes can even be created and implemented directly on the monitor – without additional workpiece measurement.

The LAS is also available as a dual camera system for the highest precision requirements. The first camera shows an image of the workpiece inserted for processing. This is the basic LAS function. The second camera provides a view directly through the beam path of the laser and delivers a high-resolution partial image of the workpiece region to be processed.

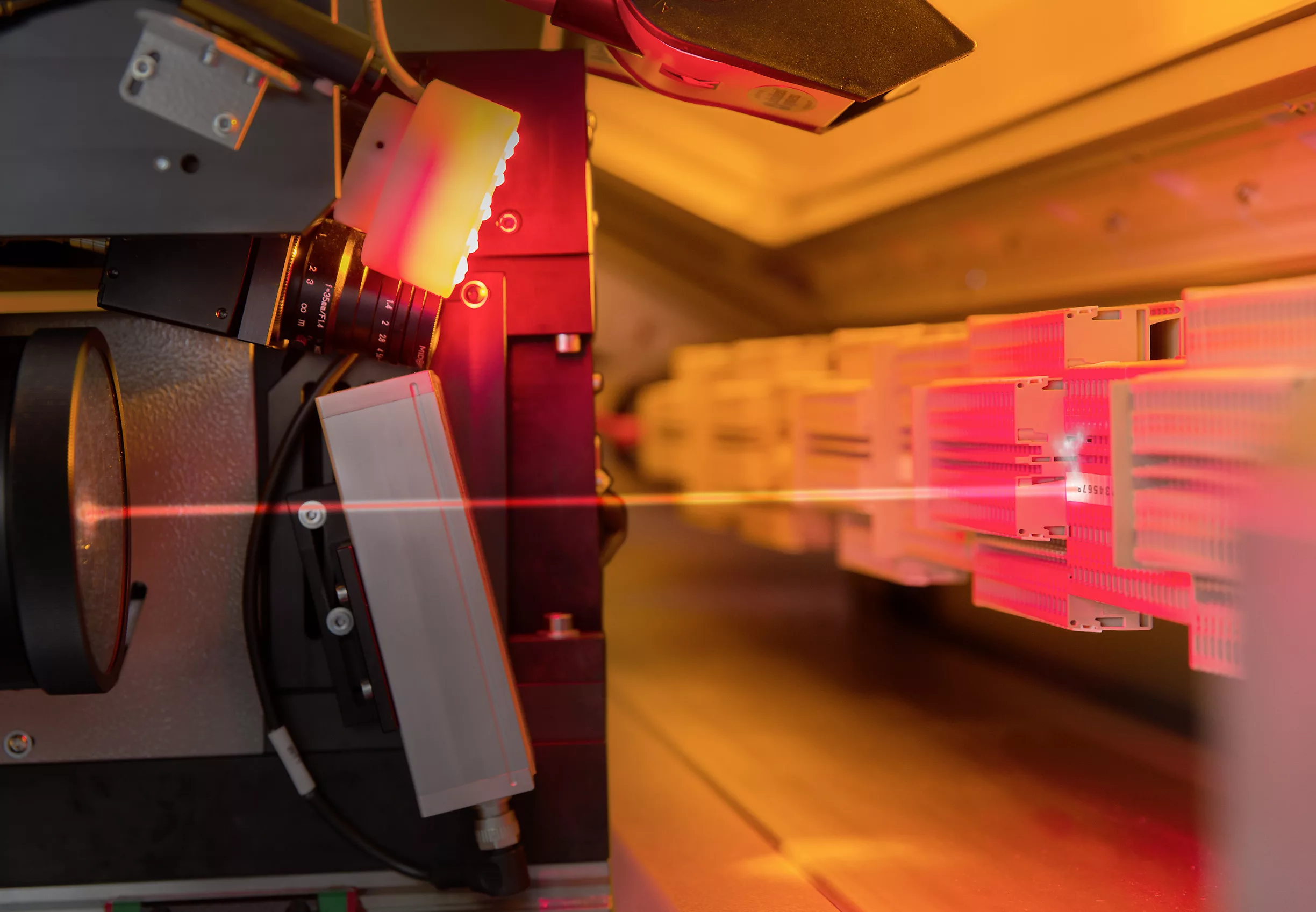

PLD – Pilot Laser Module

The Pilot Laser Module (PLD) generates a visual pointing laser that makes it much easier to position the workpiece correctly under the laser processing head. The clearly visible red light beam of the pilot laser offers several advantages: On the one hand, it marks the center of the laser processing field and also indicates a fitting rectangle according to the layout specification. Optionally, the fitting rectangles of all layout elements and, in the case of small layouts, the contour lines of the layout can also be displayed directly.

And with the help of the AC-LASER software, reference points and cutting edges can be precisely traced, allowing the laser process to be simulated before actual processing. In this way, the accuracy can be checked in advance and, if necessary, adjusted and simulated again without consuming material.

Smart software solutions for optimal results

ACSYS’ own software enables you to fully exploit the potential of your OYSTER®. In addition to numerous functions for controlling the laser processes and for automation, our software offers a wide range of interfaces and customization options, adapted to your individual requirements on request. The user-friendly interface is easy to operate and provides a wealth of information and functions for optimizing the laser process.

AC-LASER

Achieve outstanding results with the powerful modules of the AC-LASER software. Thanks to the graphical user interface, you can implement any requirement in the shortest possible time without having to compromise on design or quality. Intelligent image processing functions reduce set-up times to a minimum.

The AC-LASER software enables productivity without compromise. The close integration and uniform functionality of different modules enables you to consistently implement your ideas and requirements.

Performance features

- Camera image

The LAS – Live Adjust System enables precise positioning of even the smallest workpieces.

- Multi-axis functions

Up to 7 controlled axes can be moved simply at the click of a mouse or fully automatically.

- 3D functionality

Extensive processing options for 3D engraving with integrated depth control and digitizing functions.

- Special programming

Customer-specific layout and sequence programming as well as database connections.

- Professional text layout tools

Line spacing, spacing and typeface changes can be programmed and modified with any font installed on Windows.

- Material parameter wizard

Simple search for suitable laser parameters for a wide range of materials. Automatic creation of a parameter scale from data in an extensive parameter database.

- Barcode and DataMatrix code

Comprehensive processing module for barcodes and DataMatrix codes.

- Dual laser control

The software can manage and control two laser sources in parallel.

- Split layout

Intelligent segmentation. Large-area engravings on flat or round parts are “intelligently” separated and optimized.

- Multiple Execution

Intelligent batch processing. The laser machine can control its tasks fully automatically overnight or at weekends and process several blanks automatically.

Barcode, DataMatrix & QR code

In addition to 1D codes (barcode / barcode), 2D codes such as QR, DataMatrix, Aztec, Code One and dot codes or stacked codes are increasingly being used for marking workpieces. ACSYS offers special software modules for the generation of barcodes, DataMatrix and QR codes, which allow codes to be generated automatically on the fly. Especially when it comes to compliance with ISO 29158, durable and high-quality markings are required, particularly for printed circuit boards, in medical technology or for components in the mobility sector, as well as for the marking of wear tools.

Custom Programming

Do you need to integrate third-party software? Or do you need to connect databases or spreadsheets live? Our in-house developed software allows a wide range of customizations, from cloud connection to machine-to-machine communication with OPC/UA.

Exploit the full potential of your ACSYS laser system with our customizable software. In addition to numerous functions for controlling the laser processes and for automation, we offer you customized interfaces and customer-specific programming.

Database Integration

Whether serial numbers, product markings, data matrix and QR codes or personalization – connecting our laser systems to existing databases is now almost a standard requirement. Thanks to an open database interface, a wide range of database formats from different manufacturers can be connected. In addition to various SQL databases and flat file formats, proprietary database management systems can also be connected to ACSYS laser systems. We will be happy to advise you on the database connection of relational, object-oriented and object-relational databases.

Material Parameter Wizard

The material parameter wizard makes it easy to search for suitable laser parameters for a wide range of materials. The automatic creation of a parameter scale on the respective material and the subsequent adjustment in the software quickly and easily lead to the best results.

Professional Text Layout Tools

With the help of our convenient layout tools, you can easily combine text, graphics and images to create individual designs. Whether circular texts with individually selectable fonts or different geometric objects and patterns – you have complete design freedom for engraving, marking and structuring your products. And thanks to the intuitive graphical user interface, operation is easy even for inexperienced users.