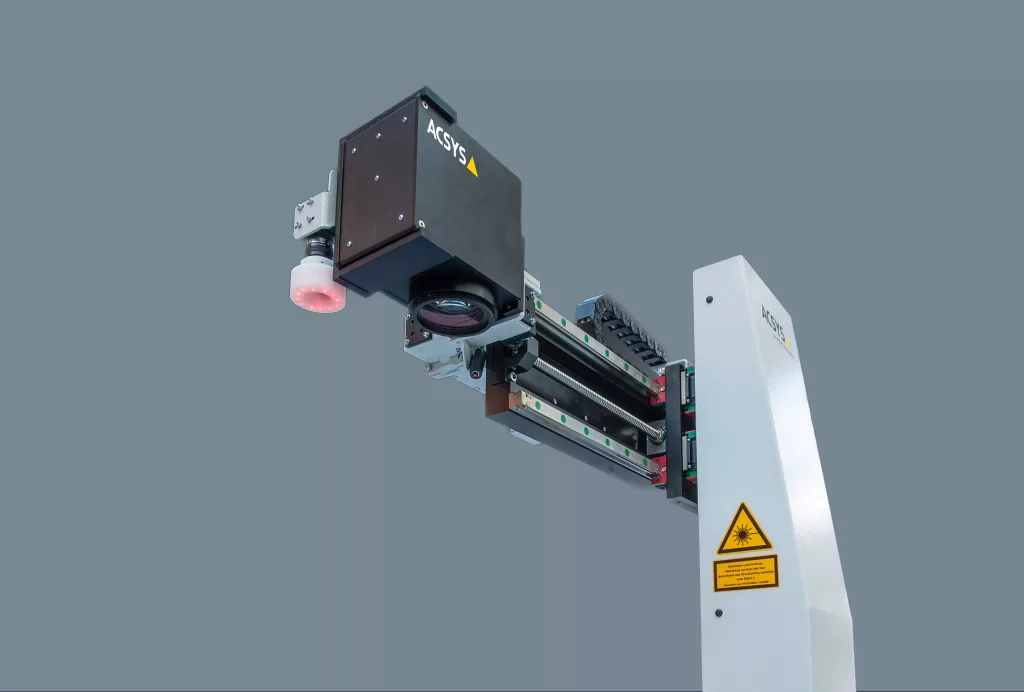

Accuracy classes and their special features

The precision of laser systems depends on several factors, as well as the area of application. Accuracy is important when engraving and marking in order to create clear and legible markings on different materials. When laser structuring surfaces, precision is required to create microscopic textures that can influence specific properties such as friction or adhesion. Precise cuts, weld seams and drill holes play a central role in the production of complex components. The accuracy is influenced by aspects such as the stability of the laser beam, the precision of the movement systems and the finely dosed control of the energy output. Different applications require specific levels of precision, which ACSYS covers with different accuracy classes.

Accuracy class 1

Standard

Normal spindle drives without additional measuring systems are used in the standard range. With an accuracy of ±25 µm over a travel distance of 300 mm in each axis, precision is already at a high level. As a rule, axle systems made of aluminum are used.

Accuracy class 2

Precision package

Based on the standard system, additional measuring systems are used on the X and Y axes. The accuracy of the precision package is ±10 µm over a travel distance of 300 mm for the X and Y axes and ±25 µm for the Z axis and table.

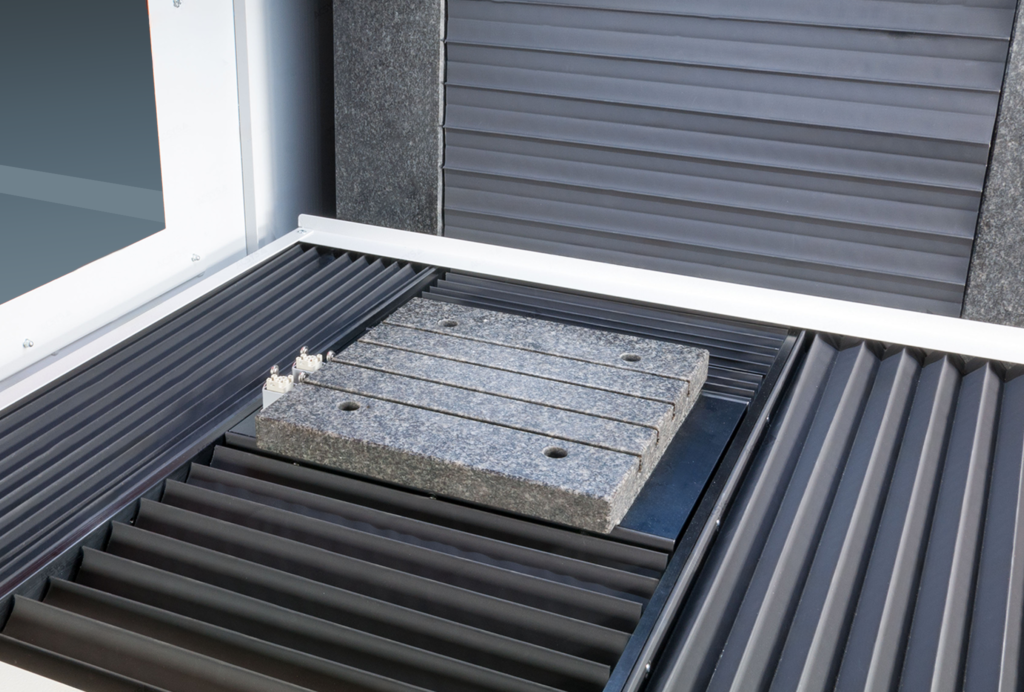

Accuracy class 3

µ package

The highest accuracy class always comes with a granite structure and additional measuring systems in all axes (X, Y, Z), except for cutting applications. The precision is ±10 µm in all axes and the table.

Your ACSYS laser expert

Do you have any questions?

I am happy to help.

Ardalan Masoumi

Business Development Manager

Telephone: +49 7154 80875 531

E-Mail: a.masoumi@acsys.de