Welding

Achieve fine, precise spot, and seam welding for both metals and plastics with ACSYS laser systems.

ACSYS laser processing systems facilitate welding processes of the highest quality. Depending on the material for a given application, different processes are used, but ACSYS welding systems consistently achieve reliable and efficient results without the need for additional material. Thanks to the option of flexible power and pulse design, our systems also make it possible to create special effects along with custom pulse shapes and trains.

Metal Welding

If metal components need to be joined together inseparably without the addition of material, laser welding is the most ideal solution. This method also provides exceptional flexibility. With the innovative fiber laser technology from ACSYS, the spectrum ranges from the finest spot welds to meter-long deep-welded seams with slim geometries and minimal distortion. Thanks to the very effective focal depth of our lasers, process-tolerant welding is possible even with materials of different wall thicknesses or when the alignment is not perfectly perpendicular.

ACSYS laser processing systems are capable of both metal welding processes, heat conduction welding (melt or fusion welding), and deep penetration welding (keyhole welding).

Heat Conduction Welding

In heat conduction welding, the laser only melts the surface layer of the material. The materials flow into each other and then solidify, creating a durable and lasting connection. The process achieves welding depths of typically < 1 mm and is well-suited for joining thin-walled parts. The laser produces a smooth, rounded weld seam that requires no post-processing.

Deep Welding

During deep penetration welding, the laser beam creates a vapor capillary in the material, also known as a keyhole. This extends to approximately 1.5 times the diameter of the laser beam focus and is guided through the workpiece by the system’s movement control. The molten metal flows around the capillary and solidifies behind it, forming a deep, narrow weld seam with a uniform structure.

This process joins multiple layers of material at once and achieves high welding depths. It combines excellent efficiency and high welding speeds with a very small heat-affected zone, which protects the material and prevents warping.

Plastic welding

Laser welding of plastics is carried out using the overlap welding process and works on the principle of laser absorption welding. In this method, the two joining partners are placed on top of each other. The laser beam penetrates the upper joining partner, and the energy is absorbed by the lower joining partner, which heats up. The heat is then transferred back to the upper joining partner, forming a common fusion band. As the material cools, pressure is applied from the outside to create a high-quality welded joint.

For the best results, the materials used must be the same or compatible, and a component-specific optimized laser technology must be selected for welding. Our team is happy to advise you in selecting the right setup.

Proven Expertise in Advanced Laser Welding Processes

Since our founding in 2003, we have become a recognized industry leader in high-precision laser technology, backed by a team of over 120 specialists who are dedicated to driving innovation. Our reputation is built on consistent advancement and a strong commitment to customer success.

Key factors that further reinforce our credibility in advanced laser welding processes include:

Certified standards – We feature certifications for DIN ISO 9001:2015 and DIN ISO 14001:2015, helping us to supply the highest quality systems and products

Sustainable operations – Our facilities are run by green electricity from hydropower, feature environmentally-friendly building designs, and incorporate other sustainability projects like job bike leasing and more

Strategic partnerships – We collaborate with leading laser research institutes and other global companies to drive innovation and future-oriented thinking

Global track record – We have commissioned over 2,000 laser systems for customers in demanding industries worldwide

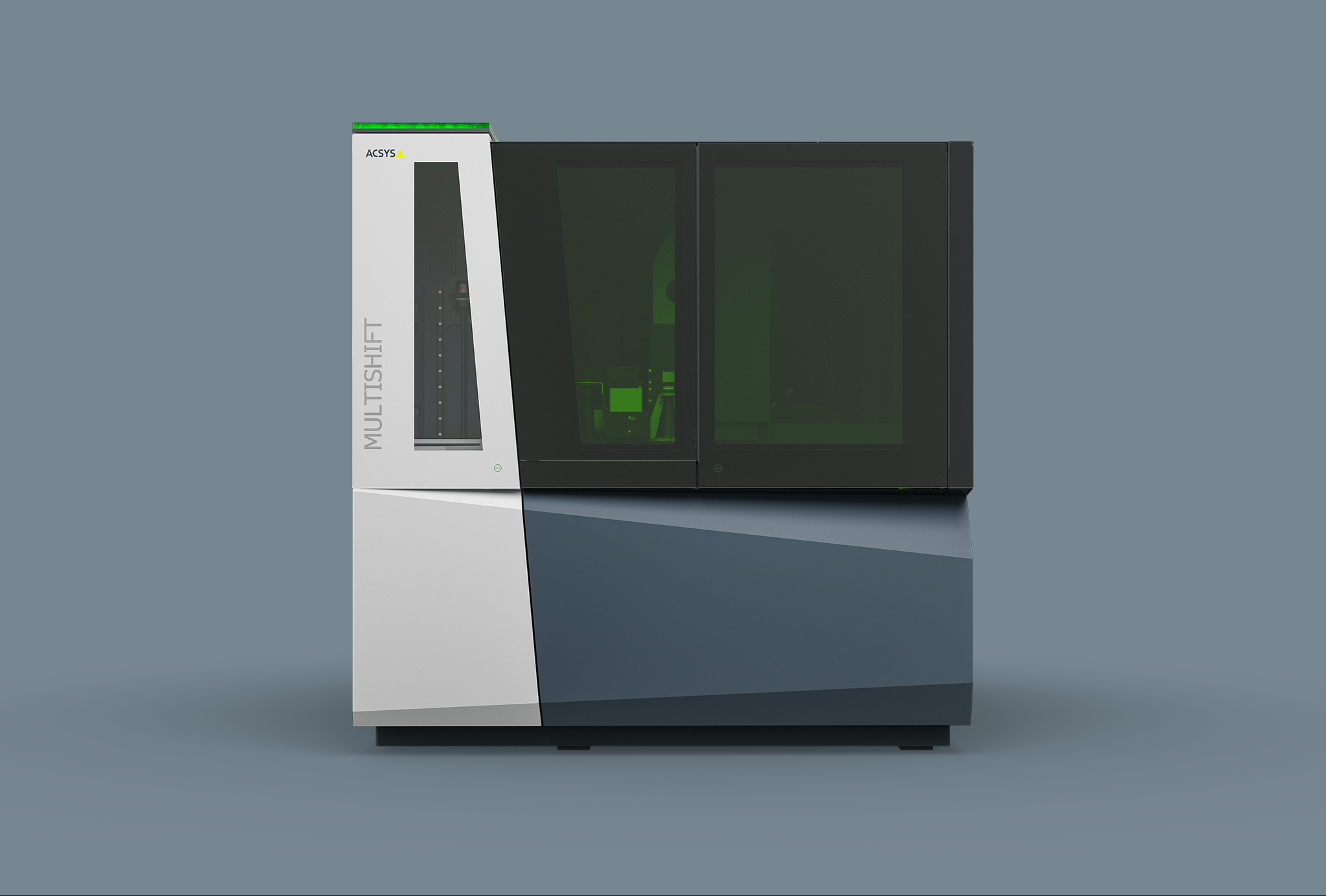

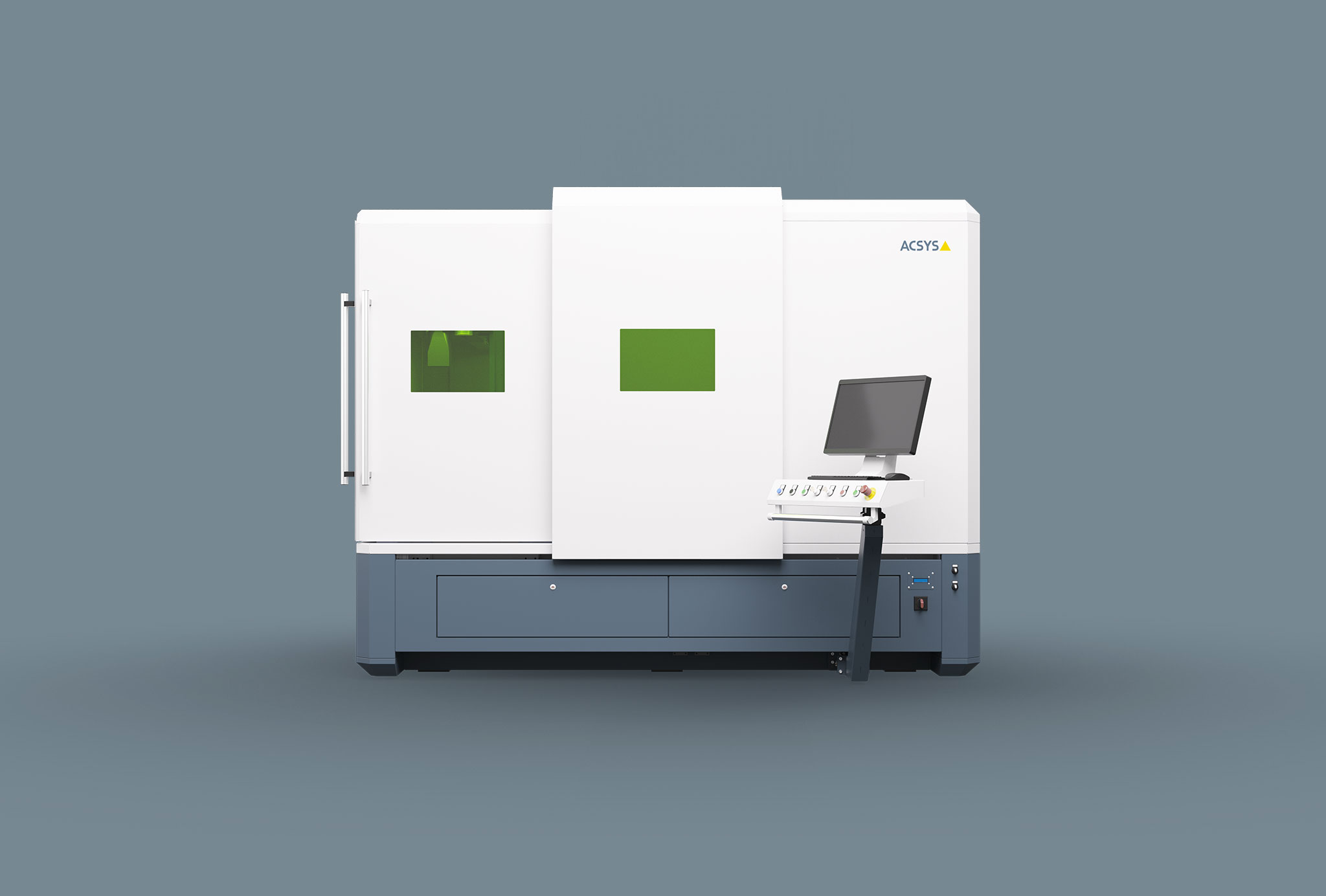

Products and solutions

Want to Know More About the Capabilities of Our Laser Welding Systems?

Are you looking for laser welding systems with diverse functionalities? Customer-specific adaptations are almost always possible with laser systems from ACSYS. Get in touch with our team today to discuss your needs and how we can tailor a solution for you.