Cutting

Laser Cutting Machines for Complex Processes

Contactless cutting process for creating complex geometries.

At ACSYS, we supply a contactless cutting process that’s able to create complex geometries. This includes laser systems with a thermal cutting process that can work with almost all materials, including metals, plastics, and organic compounds.

Our laser cutting systems are used, for example, to produce inlays and templates as well as precisely cut components. Our systems are also capable of high-precision and fast interpolated laser cutting. There are generally three laser cutting processes, which differ in terms of the additional gas that is introduced into the parting line axially to the focused laser beam.

An Overview of Our Laser Cutting Capabilities

Laser flame cutting

Oxygen is used as the cutting gas in laser flame cutting. The oxygen is blown in at pressures of up to six bar and oxidizes the base material in the kerf. This generates additional heat energy, which accelerates the cutting process even further. The laser flame cutting process is suitable for cutting thicker sheets or producing parts quickly and efficiently, the visual appearance of which can be altered by subsequent surface finishing.

Laser fusion cutting

Nitrogen or argon is used as a reaction-inhibiting cutting gas for laser fusion cutting. The inert gases guarantee a virtually oxide-free cutting edge. They are forced into the kerf at pressures of up to 20 bar, blow out the molten metal, and cool the cutting edge in the process. The laser fusion cutting process is therefore ideal for cutting thin sheets and for workpieces that must meet high optical requirements without further processing.

Laser remote cutting

No cutting gases are used for remote laser cutting or sublimation cutting. The separation process is suitable for composite materials. The laser vaporizes these in layers, creating a fine cutting gap. One of the many strengths of the process with ACSYS systems is that we rely on fiber lasers in combination with a highly dynamic galvo scanner. This moves the laser beam and enables contour speeds of over 100 m/min – even with complex contours and high precision requirements. Additionally, the laser-cut edges have low burrs and minimal roughness. This makes the process the ideal alternative to punching; the quality is impressive, and there is no need for time-consuming production and regrinding of the punching tools.

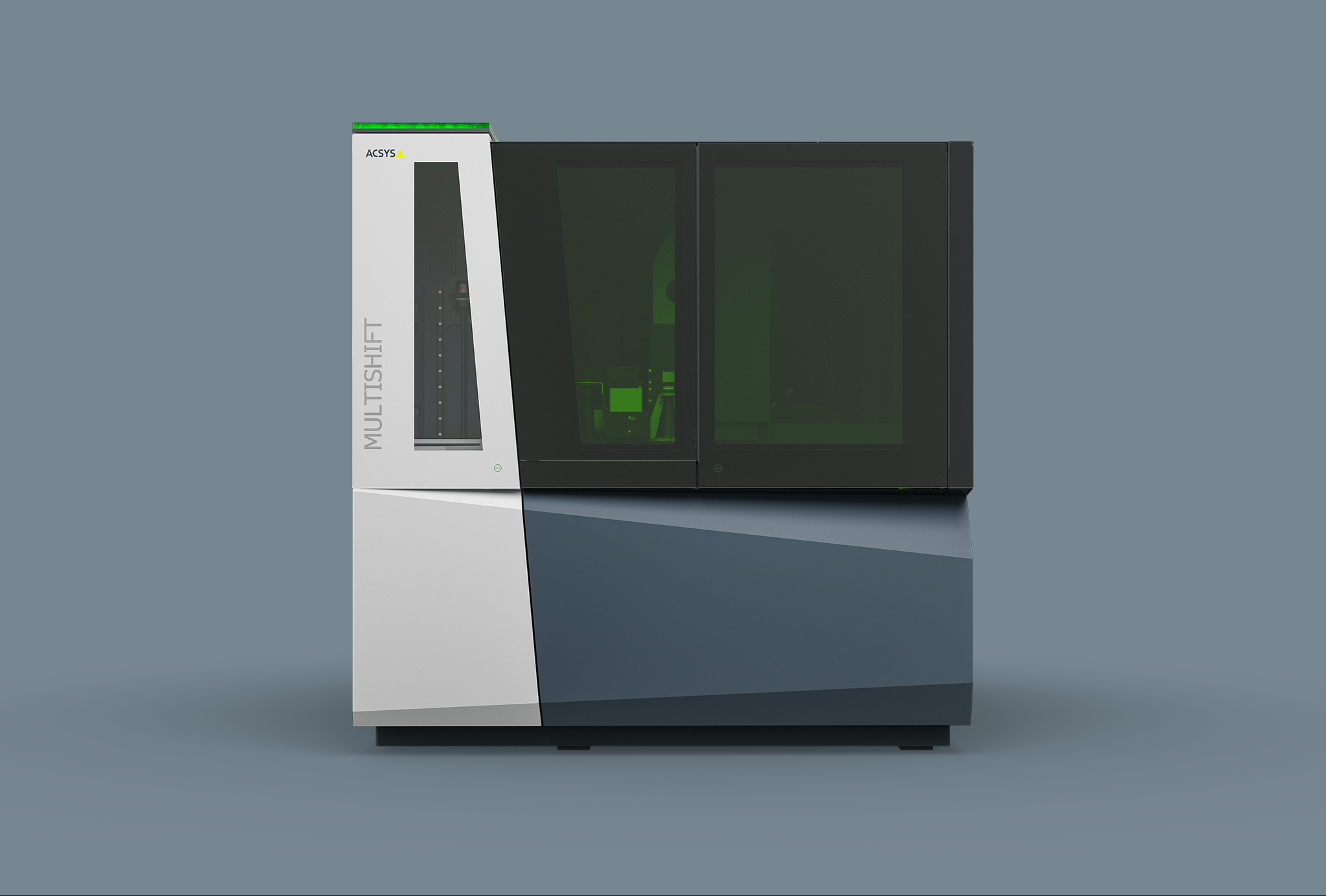

Products and solutions

Why We’re Your Destination for Laser Cutting and More

With over 20 years of experience and a passion for working with lasers, the team at ACSYS is dedicated to providing the highest quality laser cutting systems for our clientele. This includes supplying both standard and special machines that can accommodate your precise application needs.

With a team of over 120 specialists who are committed to designing innovative components, we’re proud to collaborate with some of the leading laser research institutes, as well as other global companies, to drive future-forward thinking. On top of that, our facilities feature environmentally friendly building designs and run on 100% green electricity from hydropower, as we are passionate about maintaining sustainable operations.

Industries We Serve

We provide laser cutting systems for a vast array of industries, including the following:

- Mobility

- Medical technology

- Machine and tool construction

- Minting and printing

- Jewelry making

- And more

So, no matter the industry or the project at hand, you can trust that our team of experts can provide you with a definitive laser cutting solution to streamline your operations.

Contact Us for Laser Cutting Systems

If you’ve been searching for laser cutting systems for your industrial applications, reach out to our team today to discuss options. And if you have any additional questions about our product offerings, contact us directly, as we’re happy to help.

Always stay up to date

In our Infocenter you will find the latest news, trade fairs & events as well as case studies and white papers.