Large seamless laser processing with LFR

With the triumph of electric cars, the design-defining radiator grille in its classic application is becoming superfluous. Nevertheless, the front section remains one of the most important design elements. For some years now, BMW AG has been breaking new ground in the design and functionalization of the front area. This case study looks at the role laser technology from ACSYS plays in this and how it affects other areas of product design.

Then as now

Style-defining: the kidney

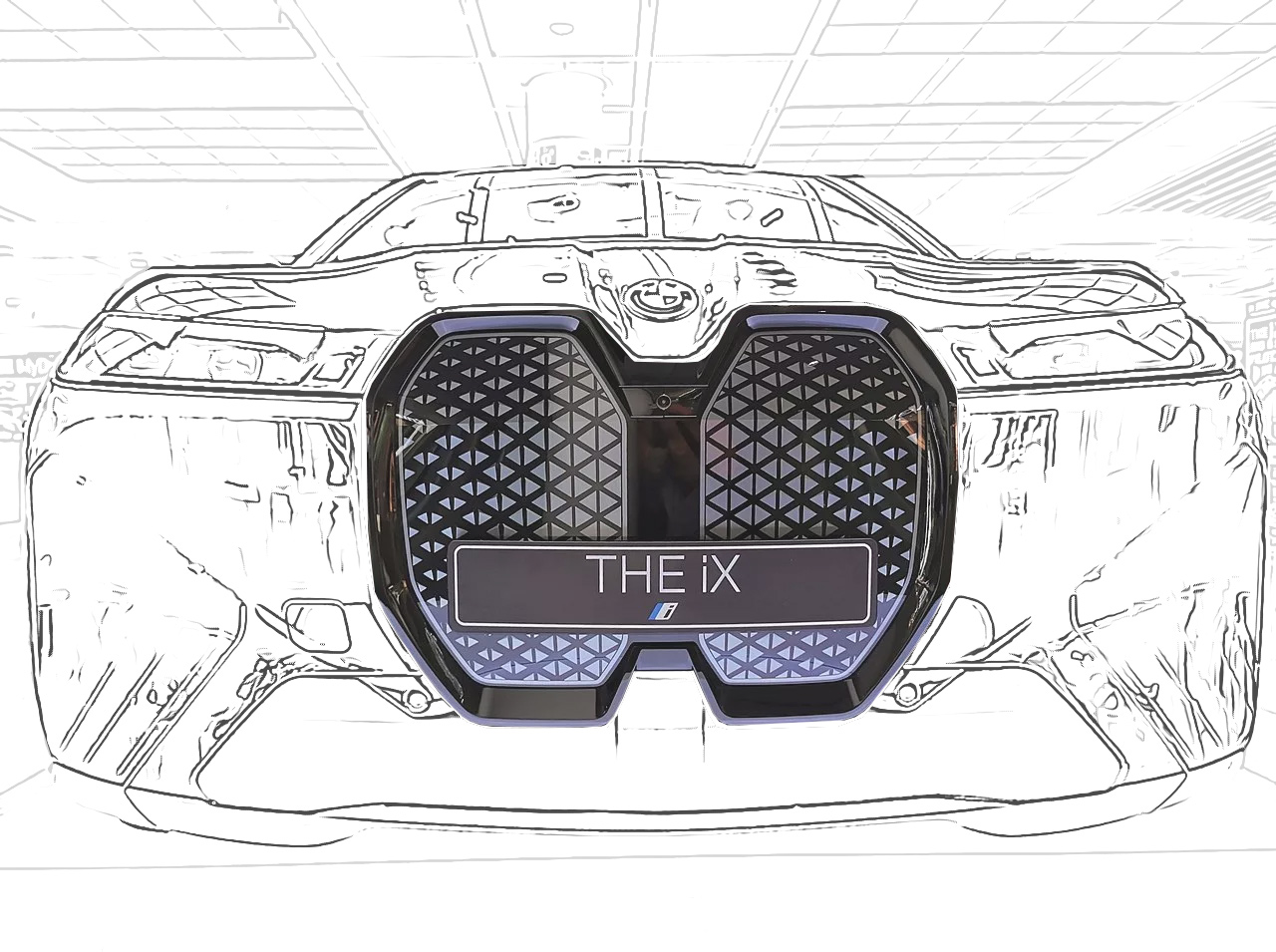

Can you imagine a BMW car without the characteristic kidney grille? Since the early 1930s, a kidney-shaped radiator grille has characterized the design of all BMW models. There is even a separate article on this. In the age of electromobility and the significantly reduced thermal radiation from electric motors, the radiator grille only has a limited temperature-regulating function. Many manufacturers have completely abandoned this component. BMW is taking a different approach. For the new development of the BMW iX, the front module was to become a design highlight with function and deliberately explore new design possibilities in the exterior.

Form and function as a challenge

Viewed from the front, the BMW iX with its realistic 3D look gives the illusion of a classic radiator front. The three-dimensional plastic component is more than just a design element. The multi-material structure contains raw parts in PC/PUR technology, as well as a heating foil that is applied very close to the surface. A key aspect is the permeability for sensors such as RADAR or LIDAR to measure distance, speed and visibility. Accordingly, it was challenging to achieve a realistic 3D appearance without compromising the desired functionalities.

First, an innovative polyurethane (PUR) flooding process is used to create the Class A surface that falls off the tool and the coloring layers are then applied on the back. However, this does not create the 3D look, nor does it guarantee functionality.

Laser technology for large-area paint removal and PVD coating

Paint removal using laser technology has been common practice in various industrial sectors for many years, for example for the creation of wheel designs in the mobility sector. For the BMW kidney, the challenge lay in the size of the component, the three-dimensional shape and the precision required to achieve the desired optical effects without having to cut it into pieces during the laser process, which leads to visible starting points in the design. The ACSYS laser experts’ answer to this challenge is Large Field Removal (LFR).

The highly developed LFR® technology allows large working areas to be treated in one go. The entire area is processed without axis movement. Thanks to continuous laser processing, the spot size of the laser remains precise and there is no visible build-up or overlapping during processing.

Partial layer ablation with Ultra Short Pulse Laser

Precise layer-by-layer removal of paints and coatings from workpieces without damaging the underlying material can be achieved primarily with femtosecond lasers (USPL). With pulse durations ranging from picoseconds to femtoseconds, they allow unprecedented control of the energy transferred to the material. In this way, ultra-short pulses can be used to create the finest structures on almost any material without significantly altering it thermally. For the BMW kidney, two 70-watt laser heads are used for simultaneous laser ablation and the associated cycle time optimization.

Conclusion

With the help of modern laser technology, new freedoms are created in the design of products and components in the interior and exterior of automobiles. Even large areas of up to 2,000 x 2,000 mm can be stripped layer by layer using the highly developed LFR® technology. And by using ultra-short pulse lasers, the finest surface structures and designs can be realized that meet the highest demands in terms of appearance and quality.

Image sources:

– Wikimedia Commons (Mateus), CC-BY

– Wikimedia Commons (Spurzem), CC-BY-SA