Structuring

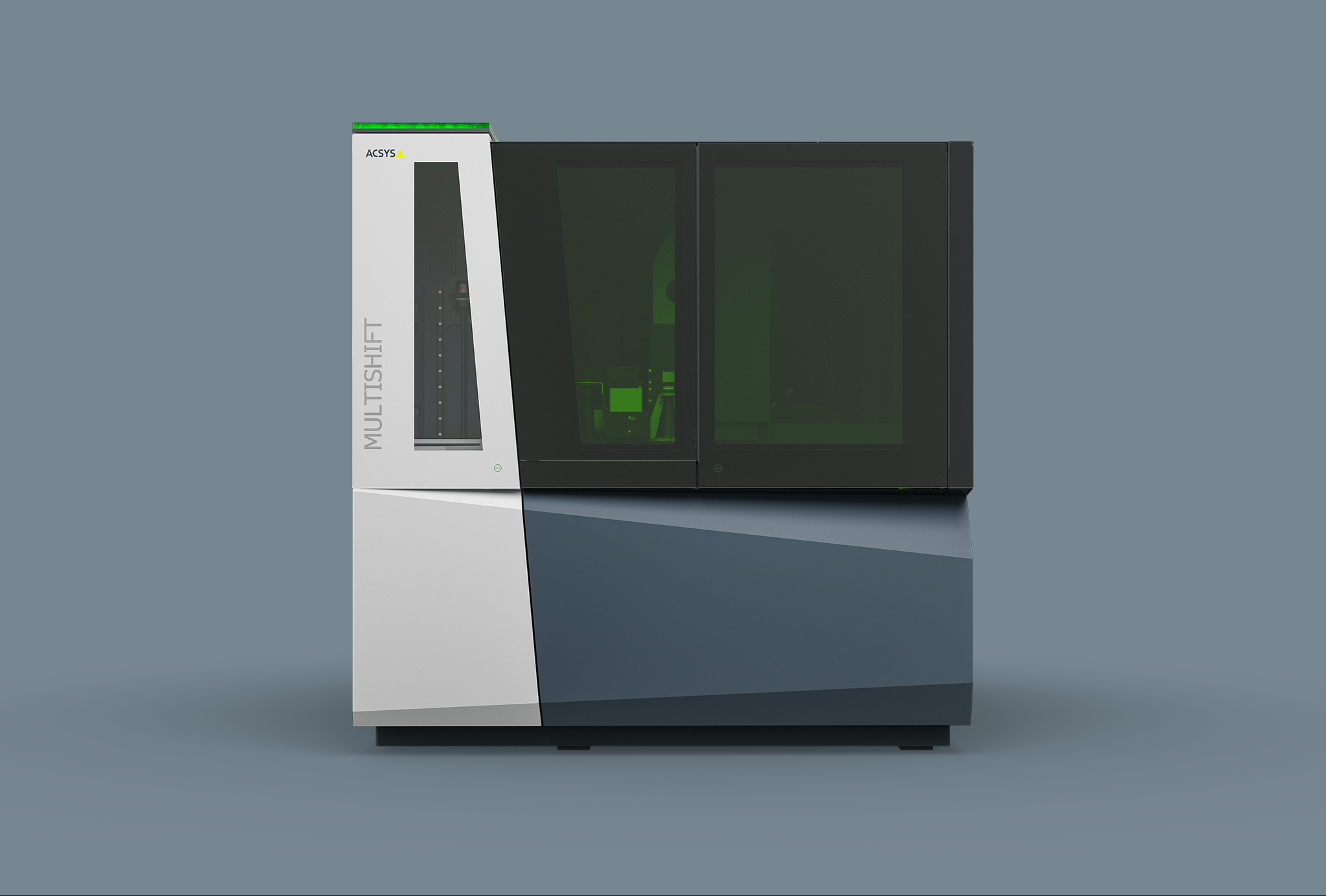

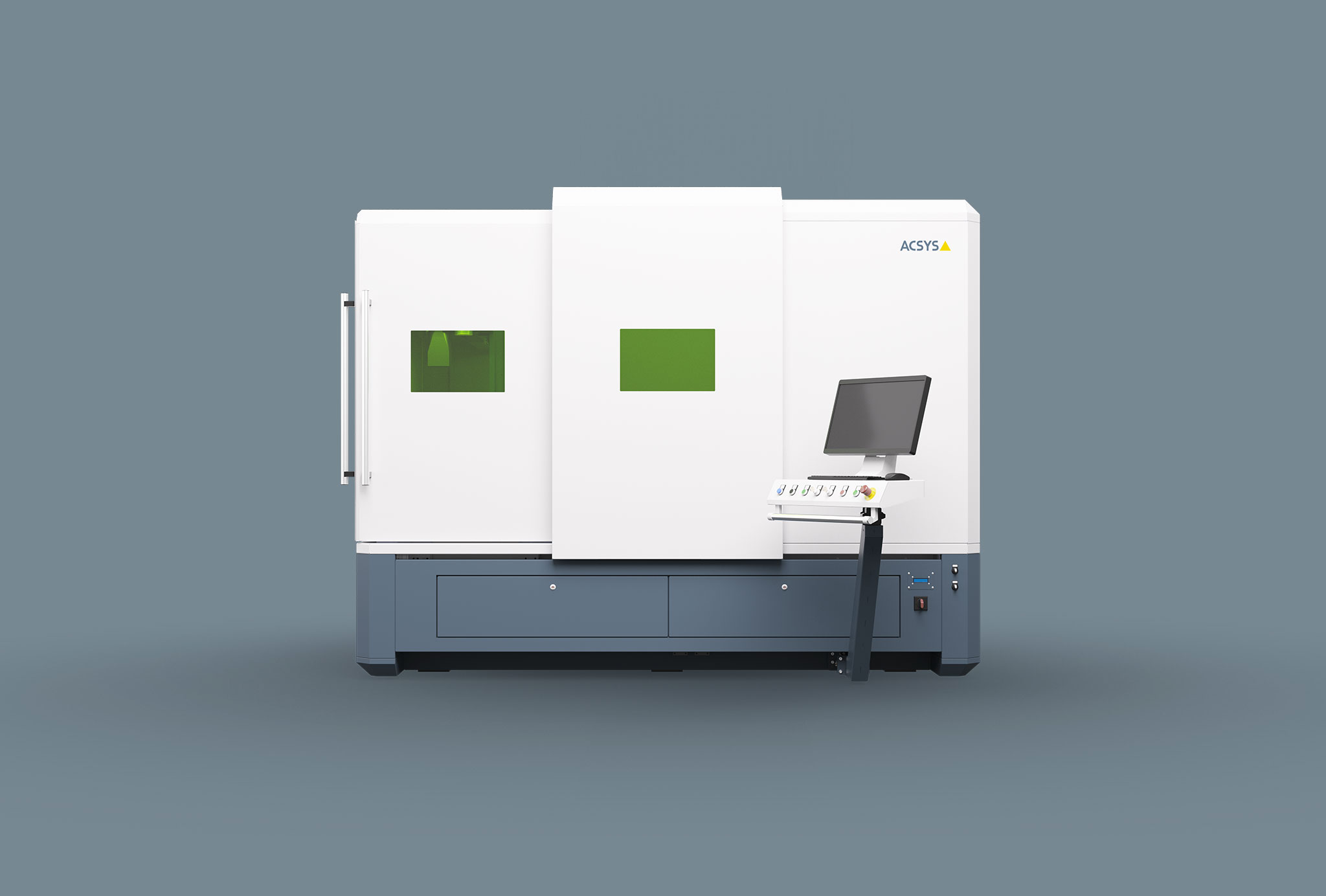

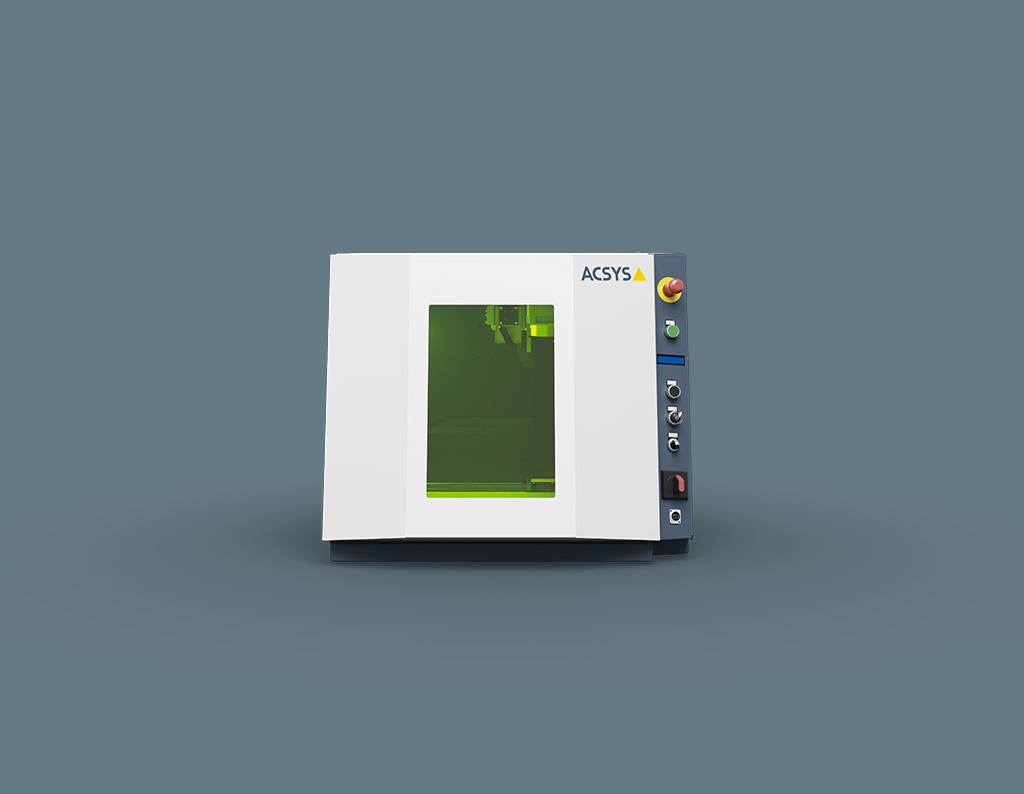

Laser Structuring Machines

Laser structuring is the process for creating microscopically structured surfaces and new surface properties.

During structuring, the material is melted in a controlled manner using a laser beam and solidified by the process control in such a way that a defined surface structure is created. Structuring can change the optical, mechanical, haptic, or biological properties of the processed components. ACSYS laser systems work with pulsed lasers such as innovative femtosecond lasers for structuring.

Large field removal: paint removal on large and complex components

Seamless laser processing of components with an area of up to 1,250 mm × 1,250 mm in one piece with the highly developed Large Field Removal technology.

Laser ablation: material removal with laser technology

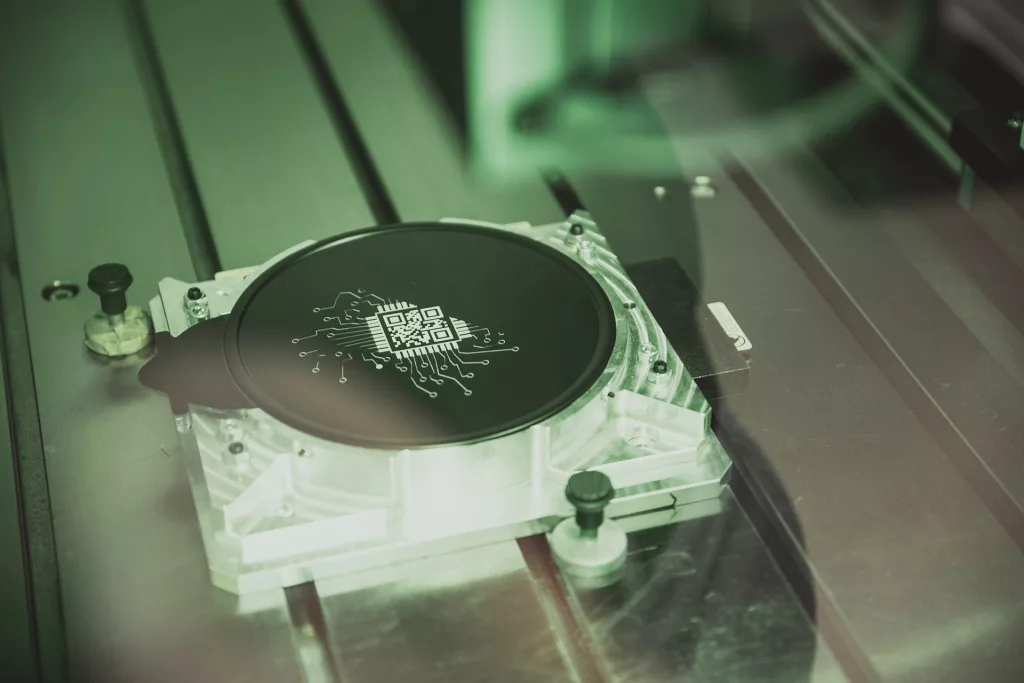

Laser ablation refers to the removal of material with the help of ultra-short pulsed laser radiation. The process is suitable for high-precision structuring and texturing of surfaces.

Microstructuring

Microstructuring can be used to create complex 3D geometries and micro- and nanoscale structures on almost any surface. ACSYS uses femtosecond lasers for this purpose. These allow a pulse duration of less than one picosecond. The heat input is so minimal that even sensitive materials such as plastics, glass, semiconductors or biological tissue can be provided with microstructures.

Surface Functionalization

The surfaces of many workpieces can also be specifically functionalized using laser structuring. ACSYS laser systems, for example, use a process called direct laser interference patterning (DLIP). This creates interference patterns that can improve the adhesion of coatings, increase the corrosion resistance of materials, or minimize surface friction.

Laserfrosting

Laserfrosting is primarily used for the production of polished molding tools such as dies for coin or medal production. It is the alternative of choice to classic frosting, in which a polished surface is partially masked and then sandblasted under a microscope. This is a very complex process, which the laser can perform much faster, more cost-effectively, and more precisely.

Polishing / Finishing

With ACSYS femtosecond lasers and our patented Pulse Forging® technology, you can make surfaces clean, smooth and shiny – similar to polishing. Neither the material properties nor the hardness of the treated material are changed. In combination with direct laser engraving, precise engravings with filigree gradients and finely polished surfaces are possible without changing tools. Pulse Forging® works more accurately than any other process and smoothes even the smallest structures with a surface accuracy of SA 0.1µm.

Products and solutions

Benefits of Laser Structuring

Laser structuring makes methods that manufacturers have used previously more efficient, precise, and non-toxic. Beyond being efficient, laser structuring offers many other benefits and advantages, including:

- Easy automation capabilities

- Complete surface preparation in a single operation

- Low operating costs and low maintenance

- Non-contact laser processing

- Masking no longer needed when replacing grit blasting operations

- Chemical and mechanical changes on the surface lead to stronger adhesive properties

Types of Applications

Laser structuring is appropriate for many materials, including metals, plastics, ceramic, and glass. Thus, versatility of laser structuring allows it to be used for various applications, which includes the following.

Adhesive Bonding

Laser structuring can be used to help prepare surfaces for adhesive bonding. For example, you may use this method to prepare bonded surfaces of batteries in vehicles. By using structuring for this application, you’ll reap benefits such as better bond strength, improved wettability, slower aging of joints, and more.

Thermal Spray Coating

The laser structuring method is also used before the thermal spray coating process, as it requires good bonding quality between the coating and the substrate. Laser structuring offers both surface roughening and surface cleaning, making it so contaminants don’t interfere with the bonding process.

Mechanical Seals

Laser structuring helps improve the performance of mechanical seals by creating patterns that reduce friction, retain lubricants, and increase the seal’s durability.

Laser Cladding

This method helps with the clad material’s adhesion to the surface through defect-free, precise surface preparation.

How ACSYS Stands Out for Laser Structuring

As a leading supplier of high-precision standard and special machines in the field of laser technology, ACSYS is dedicated to delivering top-performing solutions. When you choose ACSYS, you’ll receive benefits that include:

A dedicated team – With more than 20 years of experience and a team of 120 employees, ACSYS can tackle even the toughest projects. Our thirst for knowledge and pioneering spirit have made us a technological leader in laser micromachining.

Industry experience – From working with small to large parts, and offering diverse systems and turnkey solutions precisely tailored to applications across many industries, ACSYS can handle it all. We’ve created custom solutions for mobility, medical technology, machine and tool construction, jewelry and more!

Certification – We develop systems and methodologies that rise to the occasion and get the job done. We are committed to providing only the highest quality products, and our nominations, awards, and certificates showcase our capabilities.

Corporate social responsibility – We see it as our responsibility to society, our employees, and future generations to see the big picture while working on a small scale. That’s why we are committed to social issues as well as the environment.

Get Started on Your Structuring Applications Today!

If you’d like to explore how laser structuring can be used to create a custom solution for you,

reach out to our team today. We look forward to hearing from you!