Tailor-made laser solutions for your requirements

Customers all over the world engrave, mark, structure, weld and cut their products with high-precision laser technology from ACSYS. You too can benefit from our expertise as a technology leader. Your ACSYS advantage: We look at your entire process and optimize it with the help of individually tailored hardware and software.

Our expert team is adept at supplying laser systems to meet a diverse range of application needs, including the following:

- Laser marking – Create clear, crisp, and permanent marks for your products to incorporate logos and branding, add designs, present traceability information, and more. Our systems can also perform related processes like temper marking, deep lettering, foaming, and carbonization, giving you a wide range of output options.

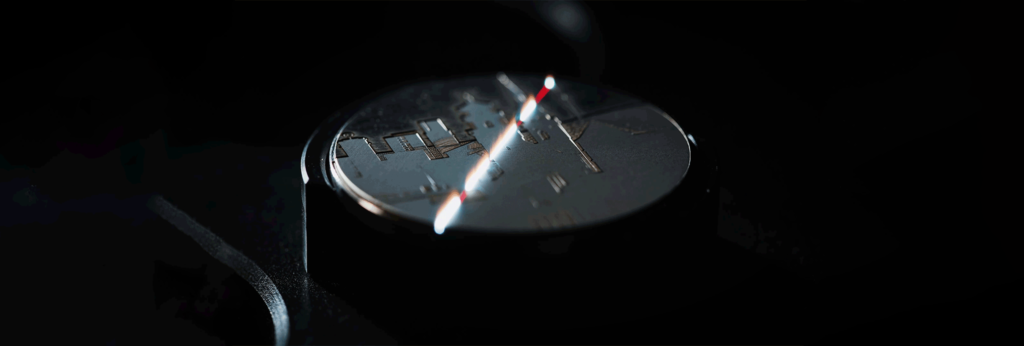

- Laser engraving – Similar to laser marking, laser engraving produces permanent marks but actually removes a small portion of the original material to create an attractive, recessed space ideal for designs, branding, product information, and more. Our systems can also facilitate deep engraving, 2.5D and 3D engraving, and micro-engraving.

- Laser structuring – By melting materials in a controlled manner via a pulsed laser beam, operatives can alter the microscopic structures of a material to produce new surface properties, impacting optical, mechanical, haptic, or biological aspects. ACSYS systems can also facilitate microstructuring, surface functionalization, laserfrosting, and polishing and finishing.

- Laser welding – If you have metal or plastic components in need of welding, ACSYS laser processing systems can provide high-quality results. Plus, with our flexible power options and pulse design, our systems can even produce special effects and special pulse shapes and trains.

- Laser cutting – A contactless process, and one which works on metals, plastics, and organic compounds alike, laser cutting offers precise and gentle cutting that will ensure reliable and repeatable results. Available subsets include laser flame cutting, laser fusion cutting, and laser remote cutting.

Tailor-made laser solutions for your requirements. All of these laser system options help us to serve diverse sectors, such as the medical field, jewelry making, coin minting, industrial operations, the automotive field, and more. Our systems can also be used with diverse materials, including most metals, plastics, gems, wood, glass, and more . Contact our team about materials and application types and we can point you in the right directions.

Always the right application

Engraving

Non-contact and wear-free process for removing material layer by layer

Marking

Efficient and permanent labeling of a wide variety of materials and workpieces

Structuring

Process for creating microscopically structured surfaces and new surface properties

Welding

Fine and precise spot and seam welding of metals and plastics

Cutting

Contactless separation process for creating complex geometries

We develop the solutions and applications of the future.

To this end, we work together with scientific institutions and cooperate with innovative companies from various sectors.