Applications of Ultra-Short Pulse (USP) Laser Processing in Industry

The use of ultra-short pulse lasers (USP) offers a wide range of possibilities in advanced material processing. USP lasers operate with pulse durations in the low picosecond to femtosecond range, enabling ultra-precise machining with virtually no thermal damage. Compared to traditional marking and engraving lasers with nanosecond pulses, USP lasers dramatically increase productivity while minimizing heat-affected zones on the workpiece surface. This makes the technology especially beneficial for processing sensitive or complex materials.

Femtosecond lasers, a specific type of USP laser, are frequently used to create ultra-fine structures with sub-micron precision. They enable cold, contact-free processing that prevents material stress, deformation, or contamination – even in the hardest materials.

From microstructuring to the precise machining of metals, plastics, ceramics, and glass, the applications are vast. USP laser processing reduces material distortion and improves processing speed, offering clear advantages over conventional manufacturing methods.

In tool and mold making, USP lasers can contour and round cutting edges and flanks of tools made from PCD or tungsten carbide, or texture hardened embossing and injection molds with maximum accuracy. In medical technology, USP lasers are used to manufacture high-precision implants and surgical instruments, meeting the highest safety and quality standards. In micro-mechanics, they are ideal for creating complex, delicate components, such as lubrication channels, microstructures, and bearing surfaces, that demand the utmost precision.

Selective material removal enables thin layers to be ablated without damaging the substrate – a major benefit in the production of encoder discs or masks, without the need for complex lithography and etching processes.

In the automotive industry, USP lasers support the processing of lightweight yet robust materials, boosting efficiency and performance. The aerospace sector also relies on this technology to manufacture highly accurate components with zero material loss. Furthermore, watch and jewelry manufacturers benefit from USP laser technology through its ability to engrave intricate, detailed designs without post-processing – enabling the creation of personalized, premium-quality pieces.

This versatility makes USP laser processing a key enabling technology across a wide spectrum of high-tech industries.

Manufacturers gain from the increased productivity and enhanced quality standards made possible by USP laser systems. As part of modern industrial production, USP laser processing marks a technological leap forward – opening the door to new dimensions of precision, performance, and innovation.

Experience the perfection of USP laser technology with ACSYS. Discover how precision, efficiency, and flexibility come together in a single tool – transforming your production into a future-ready success story.

Highest precision with USPL

Laser systems that set standards

Advantages of Femtosecond lasers

Femtosecond lasers from ACSYS can be used to process a wide variety of materials in the nanoscale range without significant thermal input. This unique advantage of ultra-short pulse lasers creates new areas of application in laser processing in almost all sectors and industries. Functionalized surfaces inspired by nature provide anti-fogging or anti-fouling effects and the finest microstructures on medical implants help them to grow together better with the surrounding tissue. Tools can be made more resistant and components tribologically optimized. With USPL, metallic surfaces can not only be provided with the finest engraving patterns, but also polished at the same time. See for yourself the many possibilities of precision machining with ACSYS Femtosecond Lasers. Customers all over the world engrave, mark, structure, weld and cut their products with high-precision laser technology from ACSYS. You too can benefit from our expertise as a technology leader, especially for ultra-short pulse lasers (USPL).

High precision

Femtosecond lasers from ACSYS are able to process materials with an extraordinarily high level of precision, allowing the finest structures and details to be created. Targeted control of the laser energy means that even complex 3D structures can be realized with a high degree of accuracy and reliability.

Low heat input

The so-called “cold processing” is a major advantage of USPL. Due to the ultra-short laser pulse, only a small amount of energy is transferred to the workpiece, resulting in minimal heat generation. This prevents deformation or damage to the material.

Flexibility with materials

With ACSYS Femtosecond Lasers you can process a wide range of materials, including metals, semiconductors, polymers and ceramics. This opens up numerous areas of application, ranging from microstructuring to polishing and finishing, and enables new types of products or product designs.

Sustainable and efficient

Thanks to their high energy efficiency and low material consumption, Femtosecond lasers from ACSYS minimize theCO2 footprint of production and save valuable resources. In contrast to conventional production methods, they also reduce the use of chemicals and harmful substances to a minimum or can even be used as a fully-fledged alternative for chemical processing.

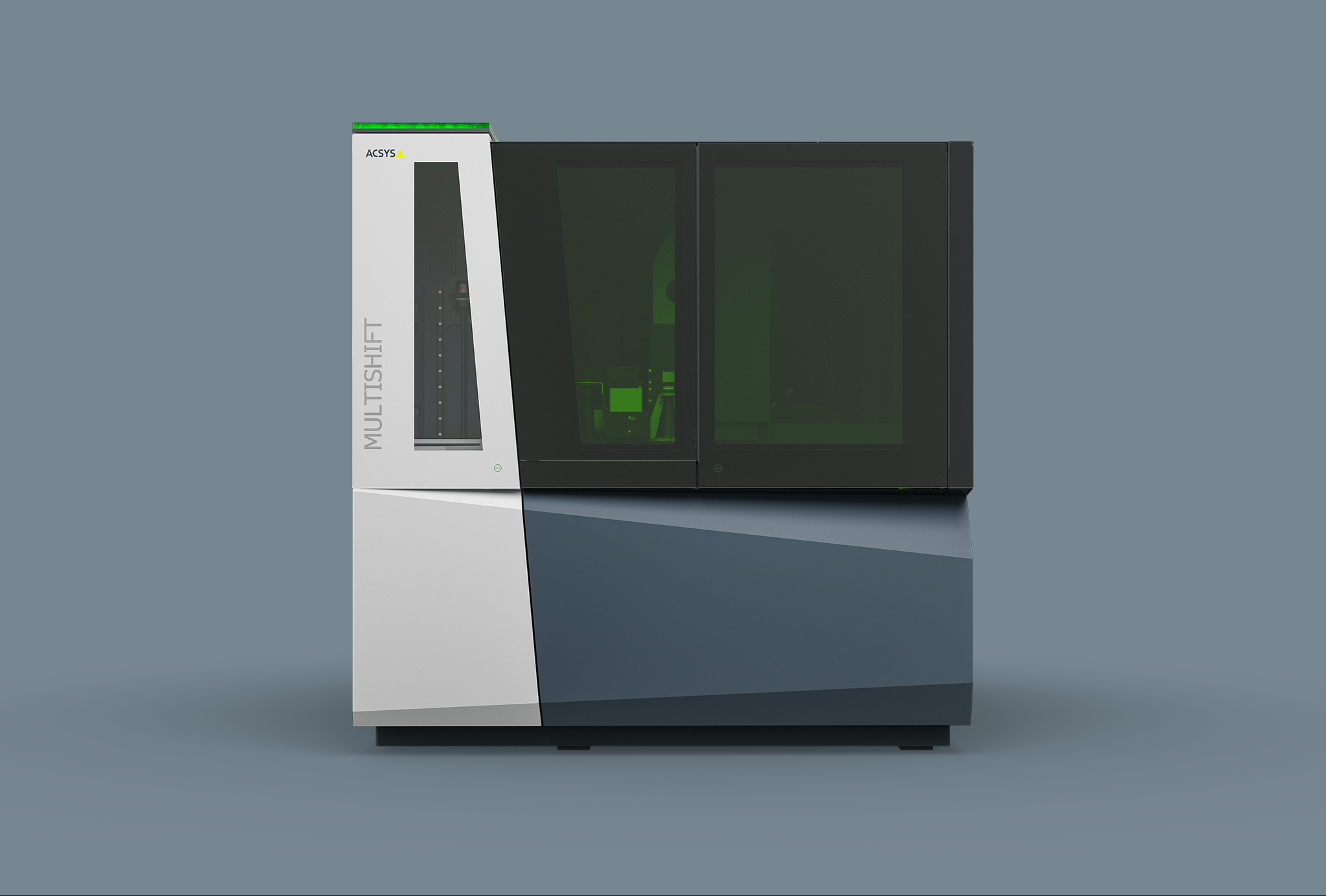

Femtosecond Laser Systems

ACSYS products and solutions are a combination of hardware and software perfectly tailored to your processes. Our femtosecond lasers open up a new dimension in precision processing for engraving, marking, structuring, welding and cutting using laser technology.

Your ACSYS expert for Mint & Print

How can I help?

Let’s get in touch.

Alexander Aminidis

Head of Global Business Unit Mint & Print

Telephone: +49 7154 80875 33

E-Mail: a.aminidis@acsys.de