Machine & tool construction

High-Precision Laser Machines for Machining

and Tooling

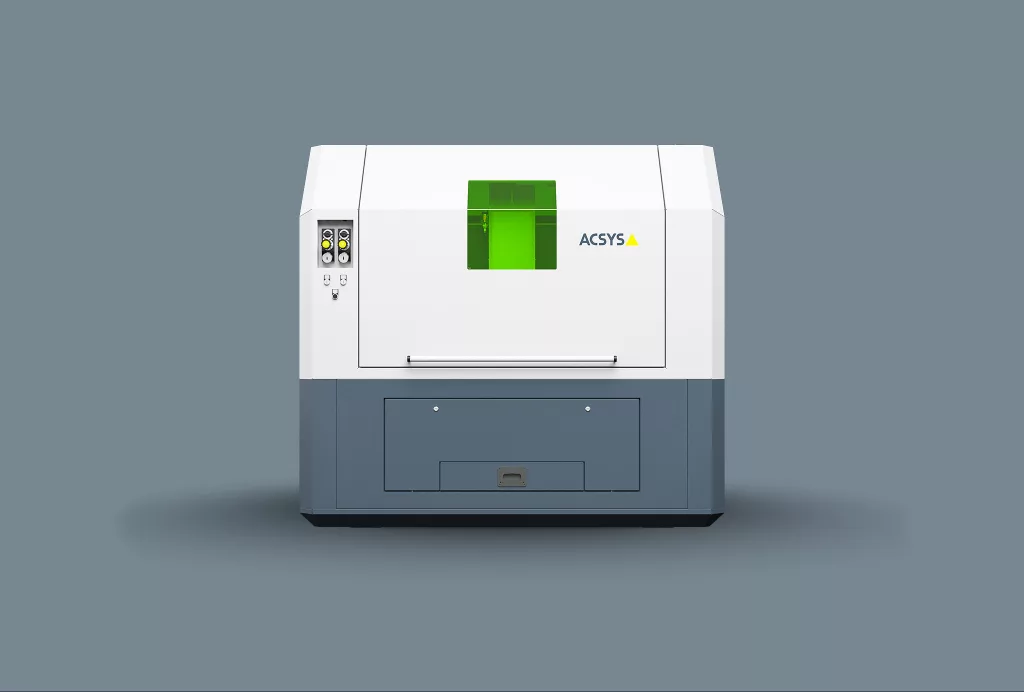

Laser processing systems from ACSYS perform important tasks in machine and tool construction. The spectrum includes laser integration in machines and systems, versatile laser applications for the manufacture of tools, and the cleaning, repair and functionalization of materials. Leading manufacturers in machine and tool construction rely on the unique combination of laser technology, software, and process know-how from ACSYS for efficient and precise laser marking, laser engraving, laser structuring, laser cutting and laser welding.

Automation

Process automation is playing an increasingly important role, especially in machine and tool construction. That is why we offer laser processing solutions tailored to your needs and individual challenges from a single source. Anyone can promise you this, but we have proven it in practice in numerous projects – it is not for nothing that market and quality-leading companies have been relying on ACSYS solutions for more than 20 years.

Our systems can help with mechanical automation, such as rotary tables, conveyor belts, or film handling with rollers for winding and unwinding, optical solutions and special solutions, such as wafer handling or the separation of bulk goods, and software solutions with automatic pallet recognition via RFID and corresponding parameterization of the system. Using effective laser systems in these processes allows you to benefit from:

- High precision and repeat accuracy

- Optimized operations that cut down on time and resources

- Reduced costs

- Maximized efficiency for production

Spot and Seam welding

Metals and plastics can be joined particularly finely, precisely, and permanently with ACSYS laser systems. Laser welding is carried out without the addition of material, which means that the processed materials retain their original properties. And with the flexible power and pulse design, special effects as well as special pulse shapes and trains can also be created.

Wheter for the smallest spots or meter-long weld seams, ACSYS laser welding systems for tool, machine, and mold making deliver:

- High-quality, precise, and efficient welds

- Increased weld and part stability

- Repeat accuracy, facilitating streamlined production

- Reliable operator control

- Both metal and plastic welding capabilities

Permanent Markings

Laser marking ensures that important information is permanently applied to tools, molds and machines. Particularly in tool and mold making, where rough conditions prevail due to corrosion, abrasion or dirt, marking with laser technology offers significant advantages over conventional methods. In addition, ACSYS laser systems offer the option to feed barcodes, serial numbers and logos into the software.

Benefit from a wide range of different laser systems, automation and processes to achieve high-quality, permanent markings and engravings – even in series production with high throughput.

There are numerous subsets of laser marking that ACSYS systems excel at, with some options including:

Laser Cutting

Laser technology can be used to cut metals and plastics, or, more precisely, to thermally separate them. ACSYS laser systems really come into their own when performing the precise cutting of flat materials with high edge quality. Our laser systems are also capable of high-precision and fast interpolated laser cutting. There are generally three laser cutting processes. These differ in the additional gas that is introduced into the parting line axially to the focused laser beam. And fine cutting with ultra short pulse laser (USPL) takes precision, edge radius, and quality to a whole new level.

Miro Engraving and Surface Functionalization

Self-cleaning, antibacterial, or non-icing surfaces are just a few examples of laser-based surface functionalization. The latest findings from bionics are used, such as via direct laser interference patterning (DLIP) to improve the adhesion of coatings, increase the corrosion resistance of materials, or minimize friction. ACSYS ultra short pulse lasers (USPL) help you to increase the service life of tools, improve precision and efficiency in production, and establish sustainable alternatives to conventional processes.

Our laser systems are adept at:

- Creating precise chip grooves that diamond grinding simple can’t match

- Producing wear-free and reliable results

- Facilitating laser texturing for improved friction and better wear resistance

- Using DLIP methods to improve adhesion or create liquid-repellent surfaces

Products and solutions

Improve Your Machining with Modern Laser Technologies

- Laser marking and laser engraving can let you clearly mark logos, branding, and product information, protect yourself from counterfeiting, and facilitate easy part traceability

- Laser structuring alters the optical, mechanical, haptic, or biological properties of your tooling or products, opening the door to completely new functionalities

- Laser cutting uses a contactless approach to create complex geometries on everything from metals to plastics to organic compounds

- Laser welding lets you produce precise welds on both metals and plastics, enhanced by flexible power and pulse designs that can create custom pulse shapes

Contact ACSYS

Our team is ready to provide you with reliable laser systems that can augment your processes and streamline operations. Contact us today to talk with one of our laser experts and we can make a recommendation for your facility.