Marking

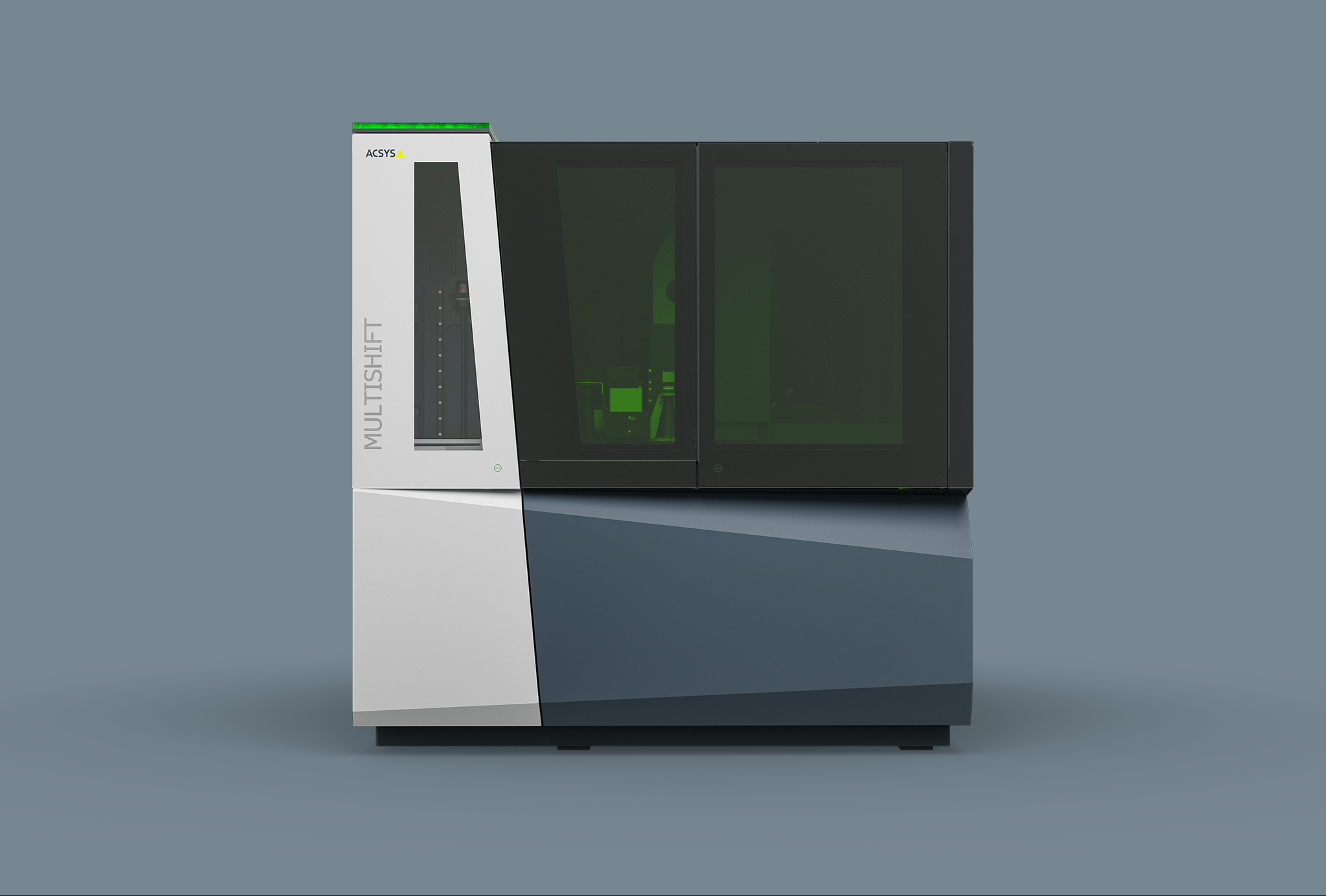

Laser Marking Machines for Complex Processes

Efficient and permanent labeling of a wide variety of materials and workpieces.

Laser marking provides efficient, precise, and permanent labeling for a wide variety of materials and workpieces.

Laser marking process is specifically designed for labeling or marking workpieces, and its main advantage is that almost any type of material can be marked with accuracy. The resulting laser markings are waterproof, smudge-proof, and durable, and can be applied quickly, individually, and automatically. These qualities make laser marking both highly efficient and the preferred choice for permanent part identification.

Tempering marking

When metal is heated, its color changes, with hues varying depending on the temperature and the duration of the heating. This phenomenon is known as the tempering effect. For example, unalloyed tool steel turns a white-yellow at a tempering temperature of 200 °C, purple-red at 270 °C, and gray at 660 °C, with other shades in between. The laserallows tempering temperatures to be achieved quickly and precisely, and it enables metal surfaces and structures to be produced in different colors without the use of additives. The markings remain temperature-stable up to the lowest tempering temperature used and these marks can be applied with maximum accuracy. ACSYS laser systems position the colors with micrometer precision.

Deep lettering / engraving marking

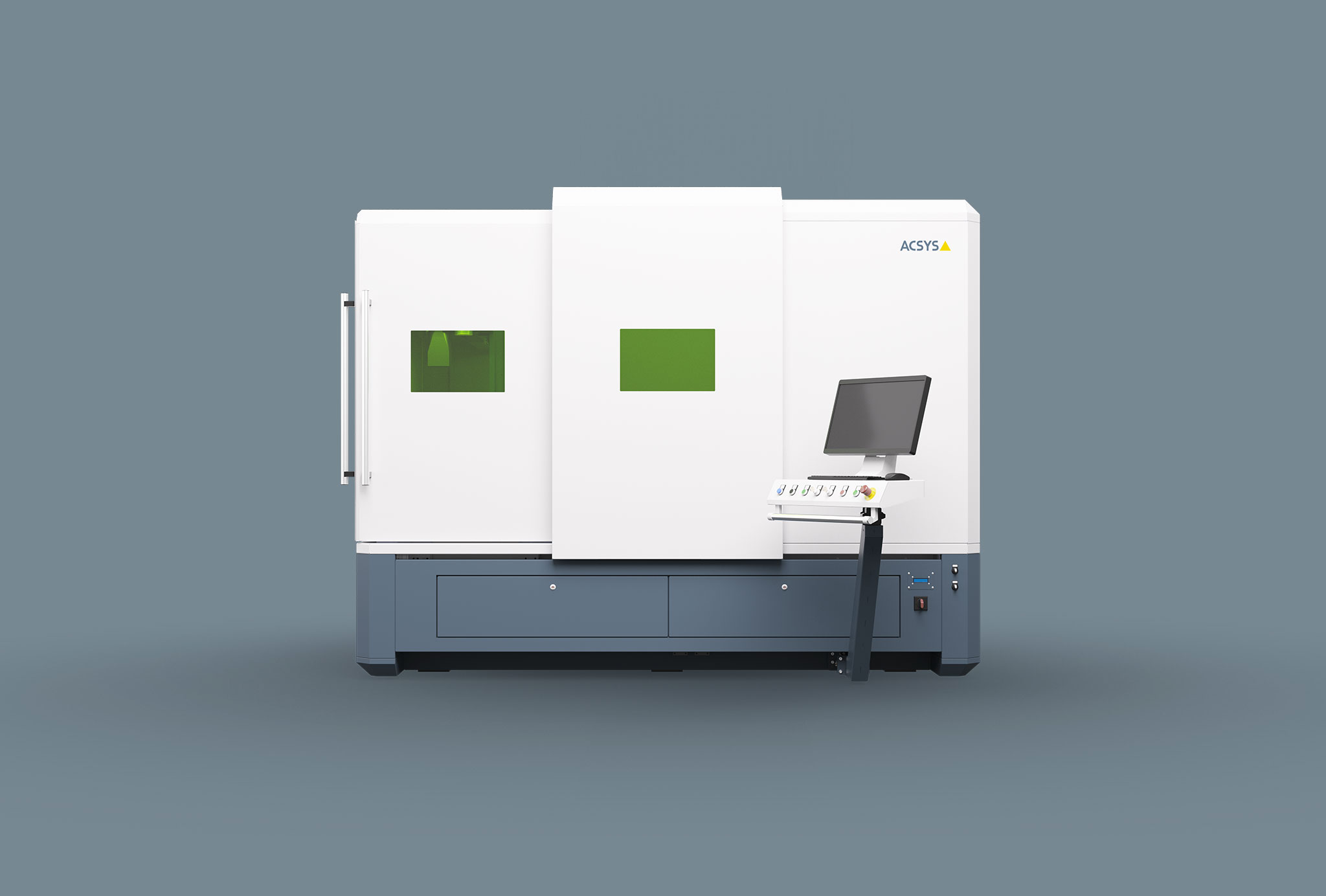

Deep marking is based on the same principle as laser engraving. In this process, material is selectively melted and vaporized via the thermal energy of the laser beam. This laser-induced removal by melt displacement results in a slightly deeper mark on the machined workpieces. Laser systems from ACSYS can even handle the process fully automatically, meaning that blanks can be marked during non-productive times without operating personnel. In addition, large-scale deep marking on flat or round parts is also possible.

Foaming

This process is particularly suitable for marking technically suitable plastics. How it works is that the laser beam melts the surface of the plastic, causing gas bubbles to form in the material and become trapped as it cools. This increases the volume of the plastic in the processed areas, which then appear slightly raised. One of the strengths of ACSYS laser systems is that, thanks to their multi-axis functionality, they can even mark large plastic webs in one piece.

Carbonize

During carbonization, the laser radiation penetrates the material and is absorbed by color pigments. These react chemically, resulting in a permanent color change in the material itself. The surface of the workpiece remains virtually unchanged. It is important to note that the effect described can only be achieved with plastic materials, some paints, and technical ceramics. The effect depends largely on the wavelength of the laser radiation, and the color changes can be controlled by selecting the pigments and the base material.

Industries That Commonly Benefit from ACSYS Laser Markers

Our laser marking machines are built for efficiency, precision, and repeatability, qualities prized by a wide range of industries. Here are just a few of the sectors that regularly use our laser markers and their common laser marking applications:

Medical technology – UDI codes, serial numbers, device IDs, lot codes, scale markings

Jewelry manufacturing – Purity marks, serial numbers, microtext, custom inscriptions

Minting and printing – Mint marks, die IDs, serial numbers, security patterns

Automotive – Part numbers, date codes, lot codes, VIN components

Industrial machining – Tool IDs, barcodes, logos, calibration scales

Why ACSYS Is the Top Choice for Laser Marking

Customizable Solutions

Combining tailored hardware, software, and automation, our team can supply complete turnkey systems designed to match your specific parts and materials. From development and design to full integration, we deliver laser marking systems that are precisely customized to your specifications.

Extensive Expertise

Our company is backed by 20 years of experience and the expertise of more than 120 skilled professionals in high-precision laser processing who’ve work with a wide variety of sectors.

Certifications

We are proud to be both DIN ISO 9001:2015 and DIN ISO 14001:2015 certified, showing our commitment to maintaining the highest quality standards in the laser industry.

Comprehensive Laser Capabilities

As a leading supplier of high-precision processes in the field of laser technology, we are proud to offer capabilities beyond laser marking, including:

Products and solutions

Service, support and customer service

Contact ACSYS for Laser Marking Services and Dedicated Customer Support. We’re proud to offer laser marking services that you can rely on. Please get in contact with our team today to discuss capabilities and systems for your application!