Engraving

Laser Engraving Machines for Complex Processes

Non-contact and wear-free process for removing material layer by layer.

Laser engraving offers a non-contact and wear-free process for removing material layer by layer, allowing organizations to permanently mark logos, graphics, serial numbers and more directly onto components.

The laser engraving process is the only modern engraving approach where the workpiece is not touched by a tool for engraving. Instead, the energy of the laser beam heats the material and vaporizes it. The laser control, optimized for engraving and special optical components, together with the AC-LASER software, enable the creation of high-precision 3D engravings companies can apply in diverse projects.

Deep engraving

With deep engraving, material is removed from the surface of the workpiece to a precisely defined depth, creating a visible and tactile mark on the workpiece. In essence, the laser beam melts the material, and the portion melted vaporizes and escapes through melt displacement. The combination of state-of-the-art laser technology and ACSYS AC-LASER software guarantees high-precision laser depth engraving.

2.5D and 3D Engraving

Just as with deep engraving, selected material is also removed from the surface of a workpiece at a chosen depth with 2.5D and 3D engraving. The difference is that the material is removed layer by layer and software-controlled at variable depths so that the desired structure is gradually revealed. In this way, predefined flank angles for embossing dies can be produced just as efficiently as complex three-dimensional surface structures, such as in mold making and other applications.

Micro-engraving

Smaller, more precise, and virtually forgery-proof, micro-engraving can be used to produce intricate structures and three-dimensional geometries in µ format. ACSYS uses state-of-the-art femtosecond lasers for this application. These lasers remove less than 1 µm of material per laser pulse, producing engravings with a correspondingly fine depth resolution. The micro-engraving process is used, for example, in the production of embossing stamps or quality seals for proof of authenticity, as well as within the jewelry industry.

Industries We Commonly Work With

Virtually any field can benefit from laser engraving, since the process delivers precise, permanent, and repeatable markings that can serve both functional and aesthetic purposes.

Some sectors, however, more frequently work with laser systems, and we’re proud of our extensive history with industries like:

Automotive – Vehicle manufacturers regularly use laser engraving machines to incorporate logos and branding, add serial numbers and additional traceability information, and permanently mark other key aspects. Along with this, the interior trim of vehicles often undergoes a graining process via laser engraving due to the process’s economic viability.

Medical technology – Equipment in the healthcare field needs to be reliable and sterile, and the non-contact approach that laser systems provide for engraving means tools can be expertly marked without marring their structural integrity. This helps medical supply companies adhere to industry regulations when engraving diverse types of information on tools and parts.

Machining and industrial – These fields use all forms of laser systems within their operations, often incorporating laser engravers into their production lines. This allows them to mark products and parts with serial numbers, bar codes, graphics, logos, safety information, and much more.

Minting and printing – Operations that mint and work with coins and similar products often use laser engraving systems due to their precision, speed, and repeatability. Plus, our patented Pulse Forging® technology allows operators to laser polish surfaces without changing tools. Other possibilities include relief engraving, frosting and surface finishing, hallmarking, intaglio engraving, and more.

Jewelry making – Precise laser fine engraving and complex 3D laser engraving are both excellent options for this sector, allowing companies to engrave watch backs, rings, pendants, bracelets, and much more. Branding, logos, instructions, and, most vital of all for this industry, personalized messages can all be engraved to the customers’ specifications.

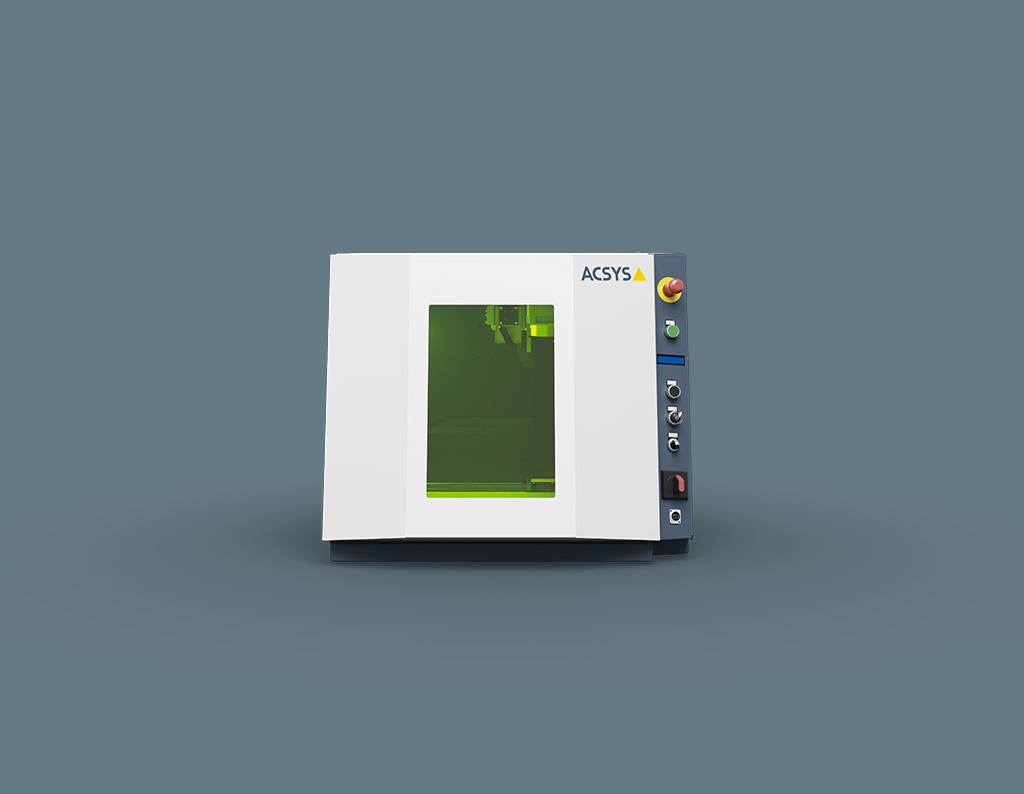

Laser Engraving Products and solutions

Laser systems and applications of the future.

Together with scientific institutions and innovative companies, we research and develop technologies and applications for novel solutions with laser technology in various areas. We’re proud to be leaders in the laser engraving space, and we look forward to continuing to advance the field.

Discover innovations from our team and be sure to contact us today to discuss laser engraving options.